Method for preparing gamma-aminobutyric acid by taking lepidotrigla abyssalis as raw material

A technology of aminobutyric acid and matchmaker fish, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as environmental pollution, discarding, waste of resources, etc., to improve economic benefits, save production costs, reduce Effects of Environmental Pollution Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

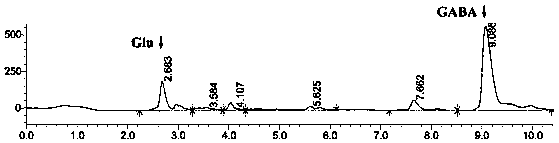

Image

Examples

Embodiment 1

[0023] (1) Remove the head, tail, fin, bone and skin of fresh matchmaker fish raw material, mix the fish meat and viscera with a homogenizer and grind into a homogenate, add water (w / v) twice the volume of the homogenate to obtain a raw material solution ;

[0024] (2) Add 2.0% (w / v) glucose to the raw material solution, adjust the pH value to 6.5, and obtain the culture solution after high temperature and high pressure sterilization.

[0025] (3) After the obtained culture solution was cooled to room temperature, the activated Enterococcus avium suspension was inoculated with 1.0% amount (v / v), and then fermented and cultivated at 37° C. for 21 hours, so that Enterococcus avium entered a stable phase, and obtained The culture solution of Enterococcus avium (in the first stage, the optimum growth conditions of Enterococcus avium in the mixed medium of matchmaker fish meat and offal are: glucose addition 2.0%, pH value 6.5, culture temperature 37 ℃, culture time 21 hours). Ent...

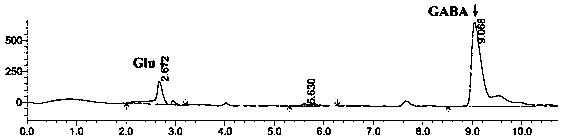

Embodiment 2

[0030] (1) The viscera of the fresh matchmaker fish is taken from the raw material, ground into a homogenate with a homogenizer, and water (w / v) twice the volume of the homogenate is added to obtain a raw material solution;

[0031] (2) Add 2.0% (w / v) glucose to the raw material solution, adjust the pH value to 6.5, and obtain the culture solution after high temperature and high pressure sterilization.

[0032] (3) After the obtained culture solution is cooled to room temperature, after inoculating the activated Enterococcus avium bacterial suspension by 1.0% amount (v / v), ferment and cultivate at 37° C. for 21 hours, so that Enterococcus avium enters a stable phase, and obtains Culture medium of Enterococcus avium.

[0033] (4) Subsequently, 1.5% sodium glutamate was added to the culture solution rich in Enterococcus avium, the pH value was adjusted to 6.0, and it was fermented and cultivated at 37°C for 4 days to obtain a GABA-rich fermentation solution with a GABA concentra...

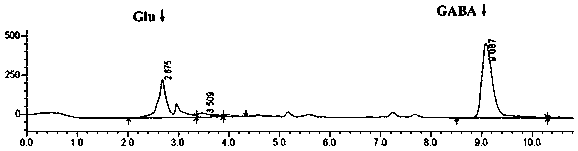

Embodiment 3

[0037] (1) After the head, tail, fin, bone and skin of the fresh matchmaker fish raw material are removed, the fish meat is ground into a homogenate with a homogenizer, and water (w / v) 5 times the mass of the homogenate is added to obtain a raw material solution;

[0038] (2) Add 1.0% (w / v) glucose to the raw material liquid, adjust the pH value to 5.5, and obtain the culture liquid after high temperature and high pressure sterilization.

[0039] (3) After the gained culture solution is cooled to room temperature, after inoculating the suspension of activated Lactobacillus brevis by 1.0% amount (v / v), ferment and cultivate at 37°C for 18 hours, so that Lactobacillus brevis enters a stable phase, (the first stage, the optimal growth conditions of Lactobacillus brevis in the matchmaker fish meat medium are: glucose addition 1.0%, pH value 5.5, culture temperature 37°C, culture time 18 hours) to obtain a culture solution rich in Lactobacillus brevis. (The fermentation strain Lactob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| body length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com