Water pressure testing device for valves and test method thereof

A hydrostatic test and valve technology, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, fluid tightness testing, etc., can solve problems such as increasing pre-tightening force, leakage, and large overall structure size , to achieve the effect of reducing the overall size and ensuring no leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the drawings and embodiments. Due to limited space, the described embodiments are some, not all, embodiments of the present invention.

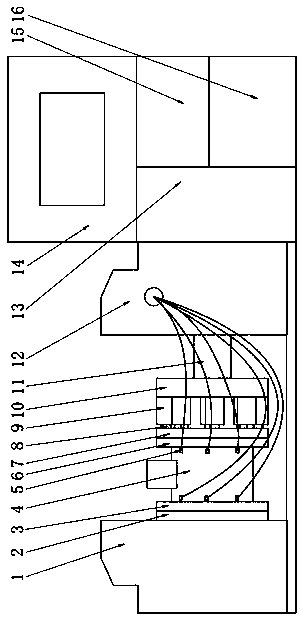

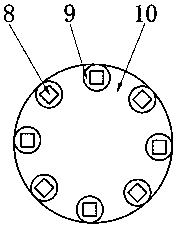

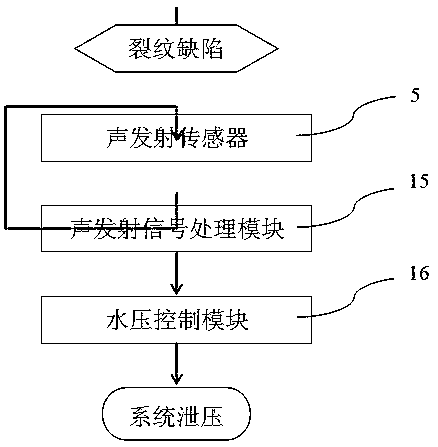

[0027] Such as Figure 1-3 As shown: the left support 1 is equipped with a pressure test left flange 2, and the right support 12 is equipped with a hydraulic cylinder. The piston rod 11 is assembled in the hydraulic cylinder and can move axially within a certain stroke range. A support plate 10 is installed at the end of the piston rod 11, and a certain number of fine-tuning oil cylinders 9 are installed on the support plate 10. The fine-tuning oil cylinders 9 are evenly distributed on the circumference, and the number is determined according to the size of the flange and the stress, and the range is 4-10. One, choose 4-6 fine-tuning oil cylinders 9 when the valve test pressure is low, choose 7-10 fine-tuning oil cylinders 9 when the test pressure is high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com