Side-chain sulfonated polysulfone proton exchange membrane and preparing method thereof

A technology of proton exchange membrane and sulfonated polysulfone, which is applied in the field of side chain type sulfonated polysulfone proton exchange membrane and its preparation, can solve the problems of poor dimensional stability of proton exchange membrane and the like, and achieves improved dimensional stability and good dimensional stability. The effect of improving the water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The method for preparing a side chain type sulfonated polysulfone proton exchange membrane of the present invention has the following specific steps:

[0037] Step 1. Prepare modified polysulfone (APS) with double bonds in the side chain. The specific steps are as follows:

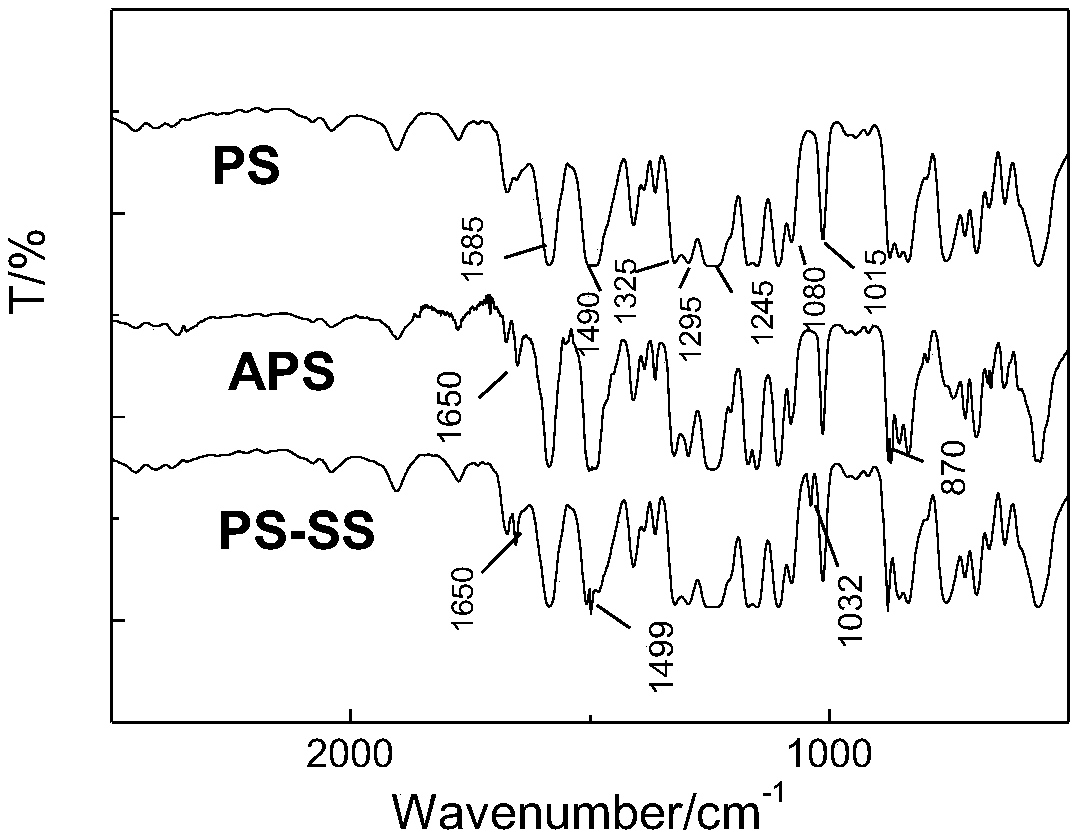

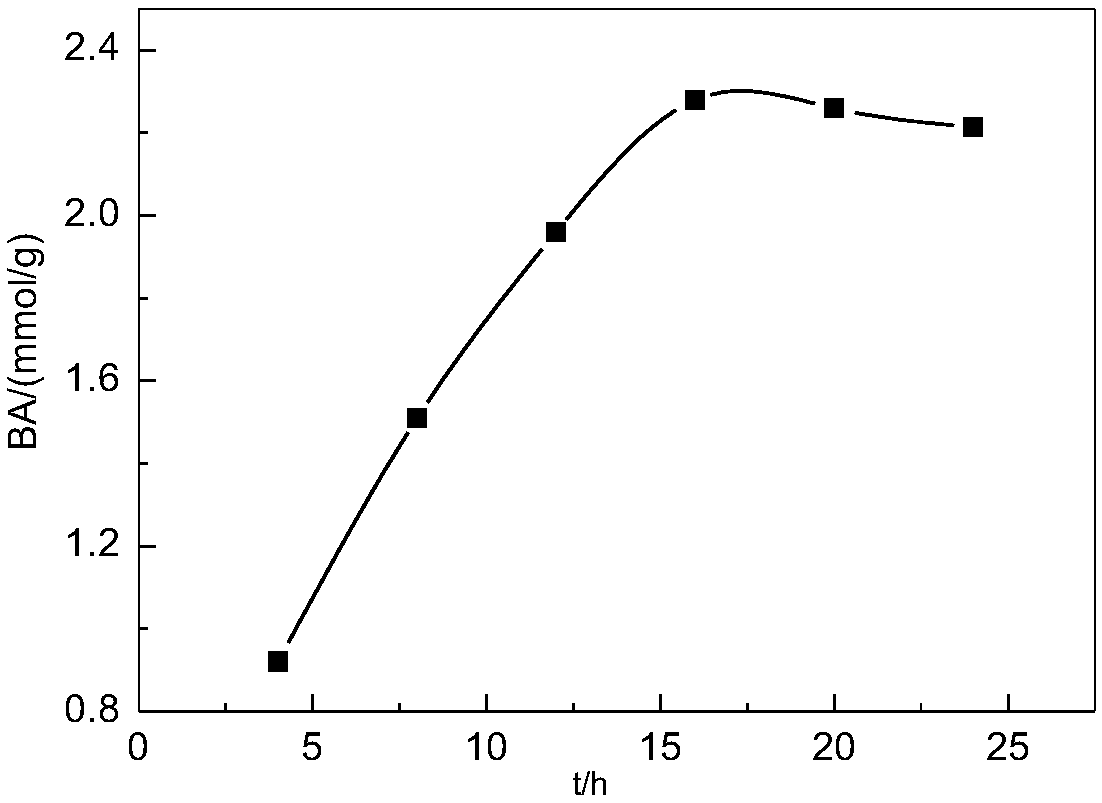

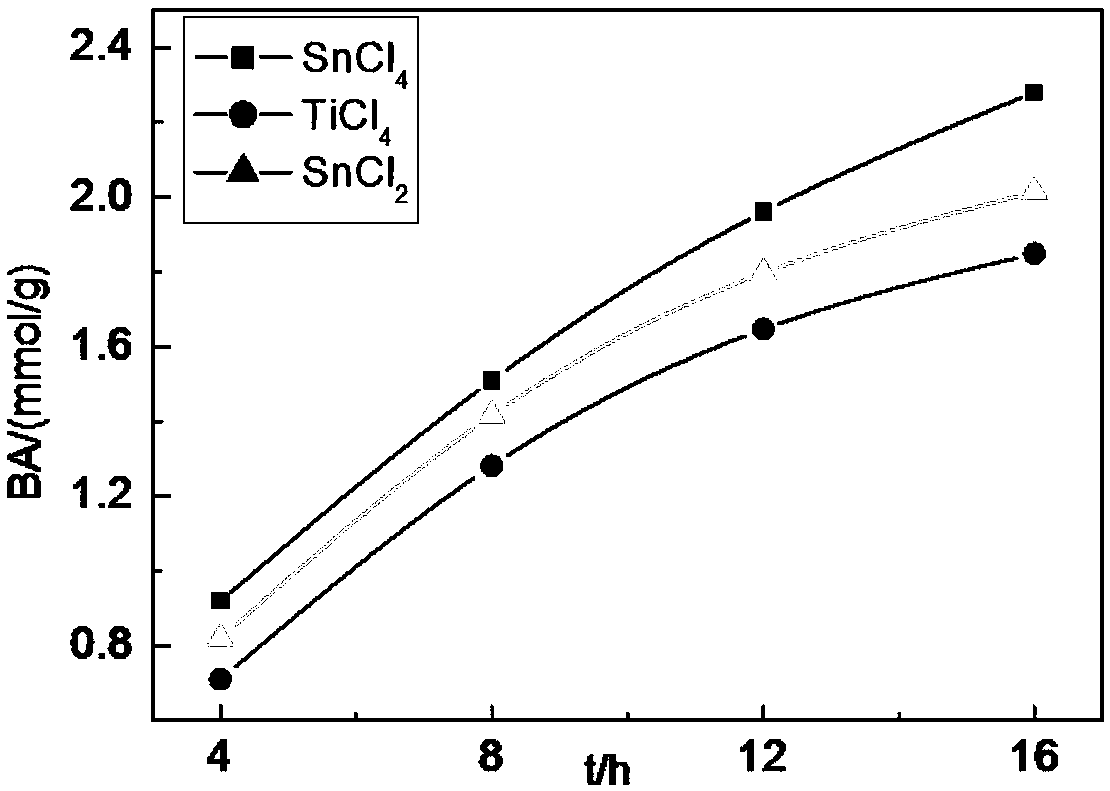

[0038] Step 1.1, after mixing the polysulfone resin (PS) and chloroform uniformly, stir to dissolve the polysulfone resin completely, then add methacryloyl chloride and tin tetrachloride, and react at 50℃~60℃ for 16h to obtain Mixture a;

[0039] Among them, the mass ratio of polysulfone resin, chloroform, methacrylic acid chloride and tin tetrachloride is 1:45:0.42:0.58;

[0040] Step 1.2, after step 1.1, use a precipitant to precipitate the solid matter in the mixed liquid a, and then centrifuge the mixed liquid a to separate the solid and liquid, and wash the obtained solid material with deionized water 3 to 5 times , Put it in an oven at 40℃~60℃ and dry for 10h~15h to obtain modified polysulfone (APS) ...

Embodiment 1

[0066] The method for preparing a side chain type sulfonated polysulfone proton exchange membrane of the present invention has the following specific steps:

[0067] Step 1. Prepare modified polysulfone (APS) with double bond at the end of the side chain. The specific steps are as follows:

[0068] Step 1.1, after mixing the polysulfone resin (PS) and chloroform uniformly, stir to dissolve the polysulfone resin completely, then add methacrylic acid chloride and tin tetrachloride, and react at 50°C for 16 hours to obtain a mixed solution a ;

[0069] Among them, the mass ratio of polysulfone resin, chloroform, methacrylic acid chloride and tin tetrachloride is 1:45:0.42:0.58;

[0070] Step 1.2, after step 1.1, the solid matter in the mixed solution a is precipitated with a precipitant, and then the mixed solution a is centrifuged to separate the solid and liquid, and the obtained solid matter is washed 4 times with deionized water and put in Dry in an oven at 40°C for 10 hours to obta...

Embodiment 2

[0080] The method for preparing a side chain type sulfonated polysulfone proton exchange membrane of the present invention has the following specific steps:

[0081] Step 1. Prepare modified polysulfone (APS) with double bond at the end of the side chain. The specific steps are as follows:

[0082] Step 1.1, after mixing the polysulfone resin (PS) and chloroform uniformly, stir to dissolve the polysulfone resin completely, then add methacryloyl chloride and tin tetrachloride, and react at 52°C for 16 hours to obtain a mixed solution a ;

[0083] Among them, the mass ratio of polysulfone resin, chloroform, methacrylic acid chloride and tin tetrachloride is 1:45:0.42:0.58;

[0084] Step 1.2, after step 1.1, the solid matter in the mixed solution a is precipitated with a precipitant, and then the mixed solution a is centrifuged to separate the solid and liquid, and the obtained solid matter is washed 4 times with deionized water and put in Dry in an oven at 60°C for 12 hours to obtain m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com