Fattening goat total mixed ration taking soybean straws as coarse fodder and preparation method

A soybean straw and roughage technology, applied in animal feed, animal feed, animal husbandry, etc., can solve the problems of less than 3%, unreasonable eating of soybean straw, waste of precious resources, etc., to achieve low cost, avoid animal picky eaters, The effect of improving feed remuneration and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

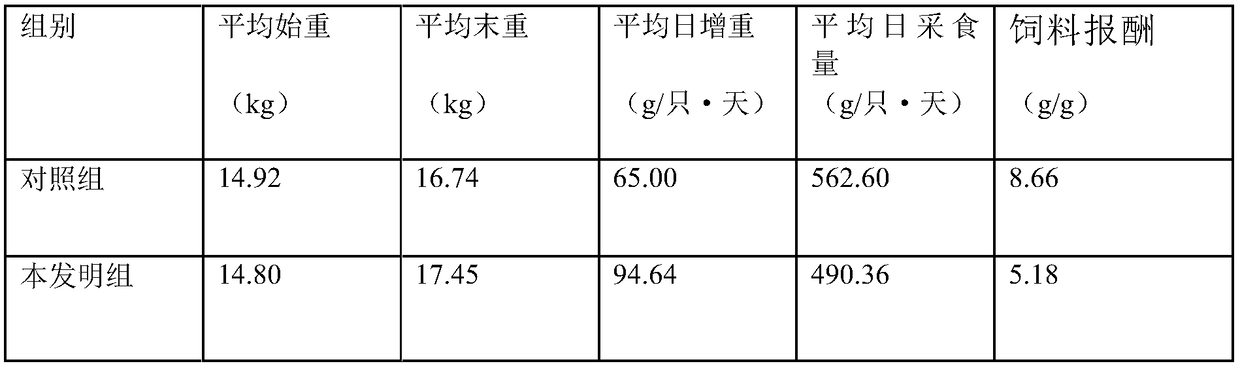

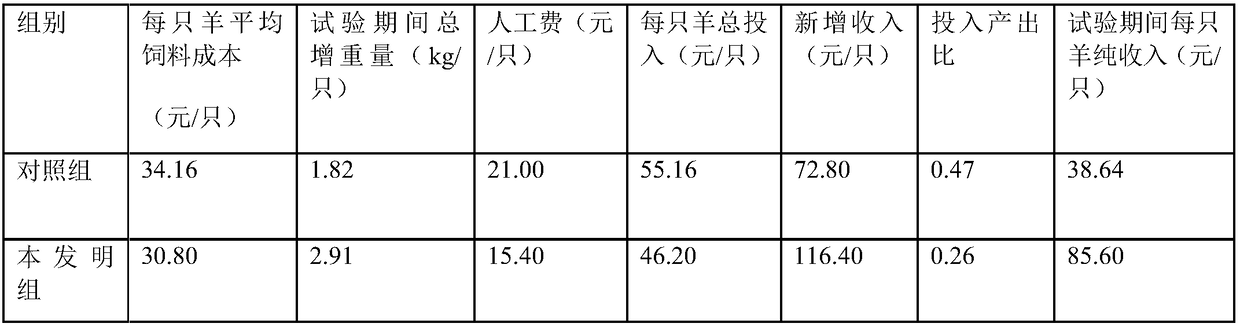

Examples

Embodiment 1

[0023] A total mixed ration (TMR) for fattening goats with soybean straw as the main roughage raw material, comprising the following raw materials in parts by weight: soybean straw powder 30, silage corn straw 35, corn grits 21, soybean meal 8, wheat bran 5, Salt 0.4, urea 0.2, additive 0.4.

[0024] The concrete preparation steps of described full mixed diet are:

[0025] (1) Preparation of soybean stalk powder: take the residues such as stalks, stems and leaves after harvesting the crop soybeans, remove mud and dry them in the sun, cut them to 3 cm with a hay cutter, and then pulverize them into powder with a grinder.

[0026] (2) Preparation of silage corn stalks: Harvest the remaining stalks after harvesting the corn at the milky stage, adjust the water content to 60% in the air for a day, and cut them into 3 cm sections with a hay cutter; chop the chopped corn The straw is directly sprayed into the silo, and the crushed straw is stepped on several times for each increase...

Embodiment 2

[0030] A total mixed ration (TMR) for fattening goats with soybean stalks as the main roughage raw material, comprising the following raw materials in parts by weight: soybean stalk powder 50, silage corn stalks 15, corn grits 25, soybean meal 5, wheat bran 4, Salt 0.4, urea 0.3, additive 0.3.

[0031] The specific preparation steps of the total mixed diet are as follows:

[0032] (1) Preparation of soybean stalk powder: take the residues such as stalks and stems and leaves after harvesting soybeans, remove mud and dry them in the sun, cut them to 3.5 cm with a hay cutter, and then pulverize them into powder with a grinder.

[0033] (2) Preparation of silage corn stalks: Harvest the remaining stalks after harvesting the corn at the milky stage, dry them in the air for a day, adjust the water content to 65%, and cut them into 3 cm sections with a hay cutter; chop the chopped corn The straw is directly sprayed into the silo, and the crushed straw is stepped on several times for...

Embodiment 3

[0037] A total mixed ration (TMR) for fattening goats with soybean stalks as the main roughage raw material, comprising the following raw materials in parts by weight: soybean stalk powder 40, silage corn stalks 25, corn grits 18, soybean meal 8, wheat bran 8, Salt 0.5, urea 0.3, additive 0.2.

[0038] The concrete preparation steps of described full mixed diet are:

[0039] (1) Preparation of soybean stalk powder: take the residues such as stalks and stems and leaves after harvesting soybeans, remove mud and dry them in the sun, cut them to 4 cm with a hay cutter, and then pulverize them into powder with a grinder.

[0040] (2) Preparation of silage corn stalks: Harvest the remaining stalks after harvesting the corn at the milky stage, dry them in the sun for a day, adjust the water content to 70%, and cut them into 4 cm sections with a hay cutter; chop the chopped corn The straw is directly sprayed into the silo, and the crushed straw is stepped on several times for each in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com