High-porosity tobacco sheet which has mint fragrance and is applied to low-temperature cigarette and production process

A technology of tobacco sheet and low-temperature cigarette, which is applied in the directions of tobacco, application, and preparation of tobacco, can solve the problems of affecting the forming of tobacco sheet by rolling method, ineffective atomization and volatilization, and poor thermal conductivity of tobacco substances, and achieves the health of operators. The effect of reducing, the production process is mature and simple, and the process is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A tobacco sheet with mint flavor and high porosity applied to low-temperature cigarettes, characterized in that:

[0029] (1) mint leaves are dried and pulverized into powder with a particle size of 30-100 mesh;

[0030] (2) Get the tobacco raw material and dry and pulverize it into a powder with a particle size of 30-100 meshes. The tobacco raw material includes any one or several mixtures of tobacco leaves, tobacco stems, and tobacco dust;

[0031] (3) According to the formula of the following mass percentages, the raw material of tobacco sheet is prepared: 60% of tobacco raw material powder, 20% of glycerin, 5% of CMC, 0.4% of ammonium bicarbonate, 11 mint leaf powder in step (1) %, water 3.6%;

[0032] (4) The raw materials in the step (3) are mixed evenly according to the proportion, and the tobacco sheet A with a thickness of 0.10-0.15 mm is manufactured by a conventional rolling method production process.

Embodiment 2

[0034] A tobacco sheet with mint flavor and high porosity applied to low-temperature cigarettes, characterized in that:

[0035] (1) mint leaves are dried and pulverized into powder with a particle size of 30-100 mesh;

[0036] (2) Get the tobacco raw material and dry and pulverize it into a powder with a particle size of 30-100 meshes. The tobacco raw material includes any one or several mixtures of tobacco leaves, tobacco stems, and tobacco dust;

[0037](3) According to the formula of the following mass percentages, the raw material of tobacco sheet is prepared: 58% of tobacco raw material powder, 22% of glycerin, 5% of sodium alginate, 0.6% of sodium bicarbonate, mint leaves in step (1) 10% powder, 4.4% water;

[0038] (4) The raw materials in the step (3) are mixed evenly according to the proportion, and the tobacco sheet B with a thickness of 0.10-0.15mm is manufactured by a conventional rolling method production process.

Embodiment 3

[0040] A tobacco sheet with mint flavor and high porosity applied to low-temperature cigarettes, characterized in that:

[0041] (1) mint leaves are dried and pulverized into powder with a particle size of 30-100 mesh;

[0042] (2) Get the tobacco raw material and dry and pulverize it into a powder with a particle size of 30-100 meshes. The tobacco raw material includes any one or several mixtures of tobacco leaves, tobacco stems, and tobacco dust;

[0043] (3) According to the formula of following mass percentages, the raw material of tobacco flakes is prepared: 55% of tobacco raw material powder, 12% of propylene glycol, 12% of glycerin, 5% of guar gum, 0.6% of aluminum potassium sulfate in step (2), step (1) Mint leaf powder 12%, water 3.4%;

[0044] (4) The raw materials in the step (3) are mixed evenly according to the proportion, and the tobacco sheet C with a thickness of 0.10-0.15 mm is manufactured by a conventional rolling method production process.

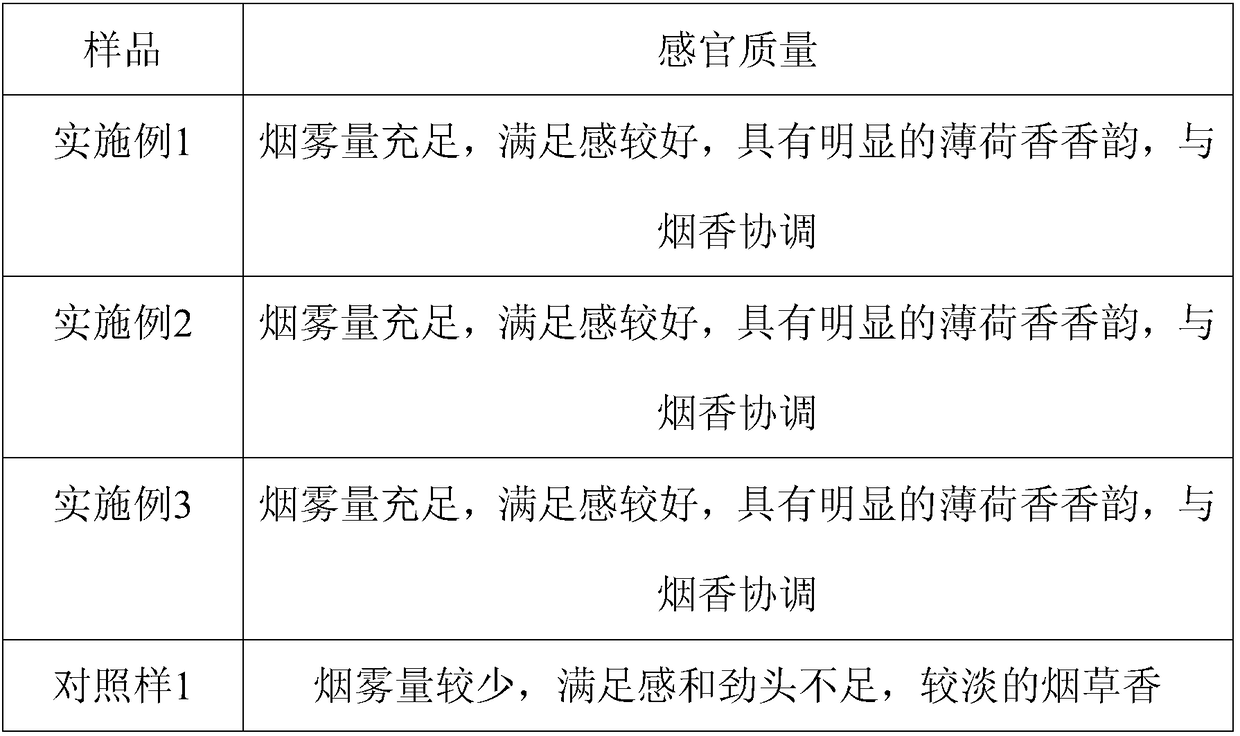

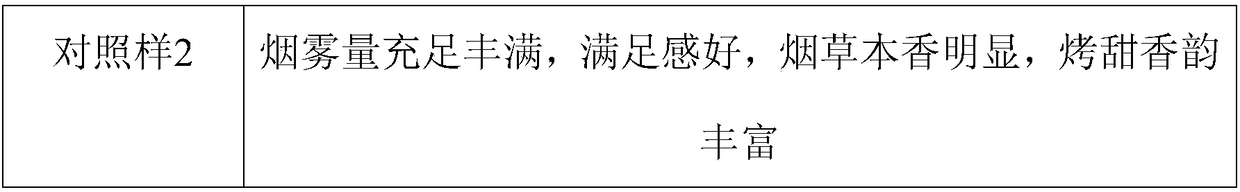

[0045] The to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com