Hydrophobic and oil-absorption modified sponge composite material and preparation method thereof

A composite material and oil modification technology, which is applied in the field of composite materials, can solve the problems of unsuitable oil absorption, etc., and achieve the effect of improving hydrophobicity and oil absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

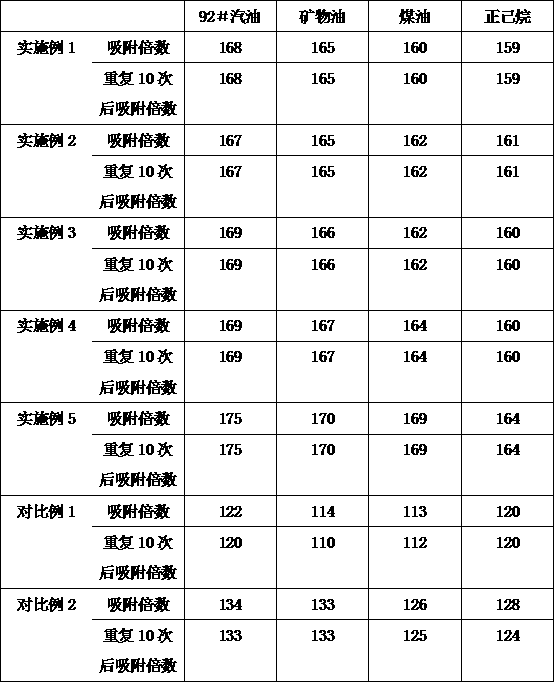

Examples

Embodiment 1

[0030] A method for preparing a hydrophobic and oil-absorbing modified sponge composite material, the specific steps are as follows:

[0031] (1) Add polyvinyl alcohol hollow microspheres to the graphene oxide aqueous solution, stir evenly, add tetraethyl orthosilicate and sodium polyacrylate, ultrasonically oscillate, add sponge to make it soak, let it stand for 20 minutes, take it out Solidification causes multiple membranes to form inside and outside the sponge;

[0032] (2) Reduction, washing, and then heating to 1300°C to remove the polyvinyl alcohol hollow microspheres, forming holes in the membrane to obtain a graphene composite sponge;

[0033] (3) Mix and stir tetrapropoxysilane, vinyltriethoxysilane and monophenylenedioctyl phosphite to make an impregnation solution, add the graphene composite sponge into the impregnation solution, immerse at 120°C for 20 minutes, take out Drain to obtain a hydrophobic and oil-absorbing modified sponge composite material.

[0034] ...

Embodiment 2

[0043] A method for preparing a hydrophobic and oil-absorbing modified sponge composite material, the specific steps are as follows:

[0044] (1) Add polyvinyl alcohol hollow microspheres to the graphene oxide aqueous solution, stir evenly, add tetraethyl orthosilicate and sodium polyacrylate, ultrasonically oscillate, add sponge to make it soak, let it stand for 30 minutes, take it out Solidification causes multiple membranes to form inside and outside the sponge;

[0045] (2) Reduction, washing, and then heating to 1400°C to remove the polyvinyl alcohol hollow microspheres, forming holes in the membrane to obtain a graphene composite sponge;

[0046] (3) Mix and stir tetrapropoxysilane, vinyltriethoxysilane and monophenylenedioctyl phosphite to make an impregnation liquid, add the graphene composite sponge into the impregnation liquid, immerse at 140°C for 30 minutes, take out Drain to obtain a hydrophobic and oil-absorbing modified sponge composite material.

[0047] Wher...

Embodiment 3

[0056] A method for preparing a hydrophobic and oil-absorbing modified sponge composite material, the specific steps are as follows:

[0057] (1) Add polyvinyl alcohol hollow microspheres to the graphene oxide aqueous solution, stir evenly, add tetraethyl orthosilicate and sodium polyacrylate, ultrasonically oscillate, add sponge to make it soak, let it stand for 20 minutes, take it out Solidification causes multiple membranes to form inside and outside the sponge;

[0058] (2) Reduction, washing, and then heating to 1400°C to remove the polyvinyl alcohol hollow microspheres, forming holes in the membrane to obtain a graphene composite sponge;

[0059] (3) Mix and stir tetrapropoxysilane, vinyltriethoxysilane and monophenylenedioctyl phosphite to make an impregnation solution, add the graphene composite sponge into the impregnation solution, immerse at 120°C for 30 minutes, take out Drain to obtain a hydrophobic and oil-absorbing modified sponge composite material.

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com