Quakeproof wafer grinder

A grinding machine and wafer technology, which is applied in grinding machine tools, grinding devices, grinding machine parts, etc., can solve the problems of poor wafer grinding stability, wafer skew, and reduced wafer grinding pass rate, etc. Chip removal time, increase yield, avoid excessive wafer processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

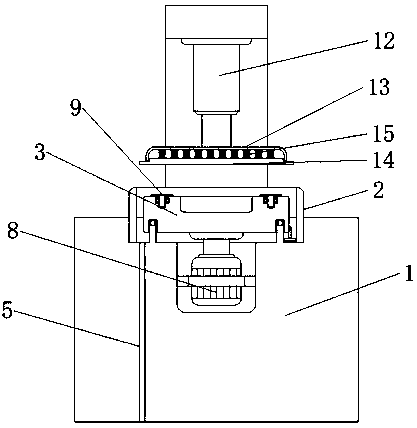

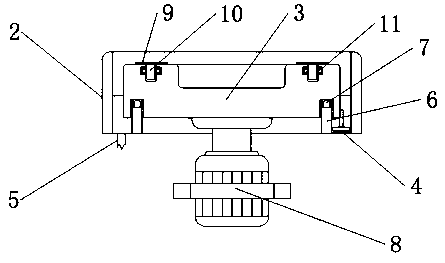

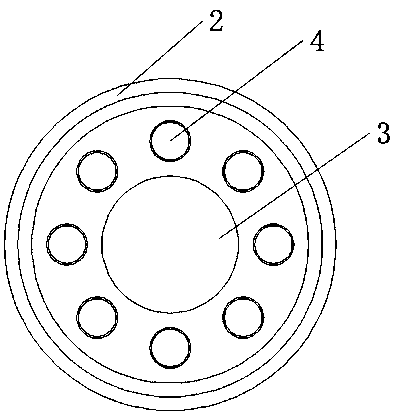

[0016] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: a shockproof wafer grinder, comprising a wafer grinder body 1, the upper surface of the wafer grinder body 1 is provided with a grinding seat 2, and the grinding seat 2 is fixed on the wafer by welding On the upper surface of the grinding machine body 1, the inside of the grinding seat 2 is provided with a runner 3, and the outer surface of the runner 3 is provided with a cleaning brush 4, and one end of the cleaning brush 4 is fixed on the outer surface of the runner 3 by welding, and the grinding seat 2 A debris discharge pipe 5 is opened inside of the wafer grinder body 1 , and the debris discharge pipe 5 runs through the interior of the wafer grinder body 1 and extends to the bottom of the wafer grinder body 1 .

[0017] In order to improve the balance of the rotation of the runner 3 and improve the precision of wafer processing, in this embodiment, preferably, the inner s...

Embodiment 2

[0022] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: a shockproof wafer grinder, comprising a wafer grinder body 1, a grinding seat 2 is arranged on the upper surface of the wafer grinder body 1, the grinding seat 2 and the wafer grinder body 1 Integral structure, the inside of the grinding seat 2 is provided with a runner 3, the outer surface of the runner 3 is provided with a cleaning brush 4, one end of the cleaning brush 4 is fixed on the outer surface of the runner 3 by welding, and the inside of the grinding seat 2 A debris discharge pipe 5 is opened, and the debris discharge pipe 5 runs through the interior of the wafer grinder body 1 and extends to the bottom of the wafer grinder body 1 .

[0023] In order to improve the balance of the rotation of the runner 3 and improve the precision of wafer processing, in this embodiment, preferably, the inner surface of the grinding base 2 is provided with a limiting ring 6, and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com