Magnetic treatment and vulcanization process cooperative processing device and method for heavy-metal-containing wastewater

A technology of collaborative treatment and magnetic treatment, applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, water/sewage treatment, etc. Environmental benefits, reduced reaction time, enhanced solubility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Cu in wastewater 2+ , Pb 2+ , Zn 2+ The concentration is 1g / L.

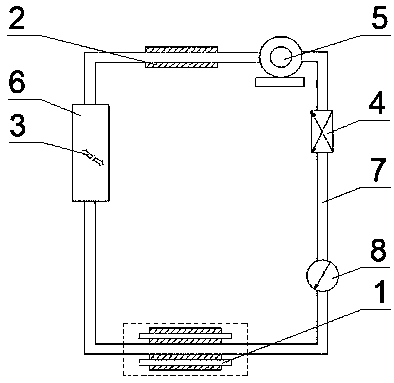

[0036] Step 1. Inject the waste water to be treated into the water tank 6, the magnetization intensity is 0.2T m, the length of the magnet 1 is 0.5m, and the magnetic induction intensity is set to 0.4T;

[0037] Step 2: Turn on the water pump 5, adjust the flow rate of the waste water to 3m / s through the valve 4 by means of the flowmeter 8, the volume of the waste water to be treated is 100L, and the cross-sectional area of the water pipe is 0.1m 2 , the magnetization time is 335s;

[0038] Step 3, turn on the stirring device 3 and the heating device 2, set the rotating speed of the stirring device 3 to 200r / min, set the temperature of the heating device 2 to 40°C, add Na at a concentration of 2.5g / L and a flow rate of 200L / h 2 S, heavy metal ion Cu was measured after 30 min 2+ , Pb 2+ , Zn 2+ The precipitation rates were 86.2%, 84%, and 81%, respectively.

Embodiment 2

[0040] Cu in wastewater 2+ , Pb 2+ , Zn 2+ The concentration is 1.5g / L.

[0041] Step 1. Inject the waste water to be treated into the water tank 6, the magnetization intensity is 0.4T m, the length of the magnet 1 is 0.5 m, and the magnetic induction intensity is set to 0.8T;

[0042] Step 2, turn on the water pump 5, adjust the flow rate of the waste water to 5 m / s through the valve 4 by means of the flow meter 8, the volume of the waste water to be treated is 100L, and the cross-sectional area of the water pipe is 0.1m 2 , the magnetization time is 200s;

[0043] Step 3, turn on the stirring device 3 and the heating device 2, set the rotating speed of the stirring device 3 to 200r / min, set the temperature of the heating device 2 to 70°C, and add Na with a concentration of 2.8g / L and a flow rate of 300L / h 2 S, heavy metal ion Cu was measured by sampling after 40min 2+ , Pb 2+ , Zn 2+ The precipitation rates were 90.3%, 87.8%, and 83.3%, respectively.

Embodiment 3

[0045] Cu in wastewater 2+ , Pb 2+ , Zn 2+ The concentration is 2g / L.

[0046] Step 1. Inject the waste water to be treated into the water tank 6, the magnetization intensity is 0.5T·m, the length of the magnet 1 is 0.5m, and the magnetic induction intensity is set to 1T;

[0047] Step 2: Turn on the water pump 5, adjust the flow rate of the waste water to 6m / s through the valve 4 by means of the flowmeter 8, the volume of the waste water to be treated is 100L, and the cross-sectional area of the water pipe is 0.1m 2 , the magnetization time is 170s;

[0048] Step 3, turn on the stirring device 3 and the heating device 2, set the rotating speed of the stirring device 3 to be 500r / min, use the temperature regulator 3 to set the temperature of the heating device 2 to be 55°C, set the concentration to 4.5g / L, and the flow rate to be 250L / min h added to Na 2 S, heavy metal ion Cu was measured by sampling after 60 min 2+ , Pb 2+ , Zn 2+ The precipitation rates were 96.5%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com