Photo-thermal driving nickel-based catalyst as well as preparation method and application thereof

A nickel-based catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc., can solve the problems of limited large-scale application, rapid deactivation, etc. The effect of improving stability and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

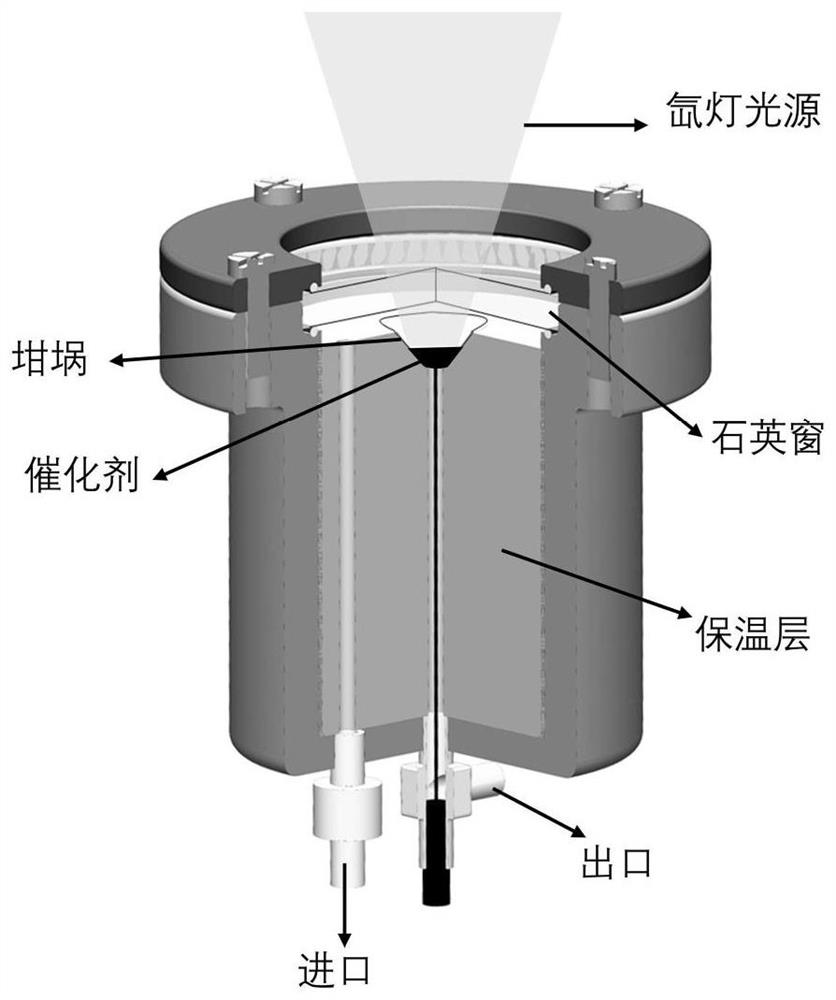

[0031] A preparation method of a photothermally driven methane dry reforming nickel-based core-shell structure catalyst is specifically prepared by the following method:

[0032] (1) Dissolve 0.164g magnesium nitrate hexahydrate, 0.135g aluminum nitrate hexahydrate, 0.12g silicon dioxide powder, and 2.7g urea in 8mL deionized water to form a first solution;

[0033] (2) Add 9 mL of ethanol to the first solution, and magnetically stir for 20 min at room temperature to form a suspension;

[0034] (3) Add 8mL of 0.1mol / L nickel nitrate solution to the suspension, then sonicate and stir for 5h;

[0035] (4) Transfer the stirred solution in (3) into a polytetrafluoroethylene liner, and put it into a high-pressure reactor for 36 hours at 190 °C;

[0036] (5) Centrifuge the mixed solution obtained after hydrothermal treatment in (4) at 8000 r / min, and wash the obtained precipitate three times with water and ethanol;

[0037] (6) drying the precipitate obtained in (5) at 80 °C overn...

Embodiment 2

[0048] A preparation method of a photothermally driven methane dry reforming nickel-based core-shell structure catalyst is specifically prepared by the following method:

[0049] (1) Dissolve 0.141g magnesium nitrate hexahydrate, 0.169g aluminum nitrate hexahydrate, 0.12g silicon dioxide powder, and 2.7g urea in 8mL deionized water to form a first solution;

[0050] (2) Add Lml of ethanol to the first solution, and magnetically stir at room temperature for 20 min to form a suspension;

[0051] (3) Add 8ml of 0.1mol / L nickel nitrate solution to the suspension, then sonicate and stir for 5h;

[0052] (4) Transfer the stirred solution in (3) into a polytetrafluoroethylene liner, and put it into an autoclave at 180°C for 40 hours of reaction;

[0053] (5) Centrifuge the mixed solution obtained after hydrothermal treatment in (4) at 8000 r / min, and wash the obtained precipitate three times with water and ethanol;

[0054] (6) drying the precipitate obtained in (5) at 80°C overnig...

Embodiment 3

[0059] A preparation method of a photothermally driven methane dry reforming nickel-based core-shell structure catalyst is specifically prepared by the following method:

[0060] (1) Dissolve 0.103g magnesium nitrate hexahydrate, 0.225g aluminum nitrate hexahydrate, 0.12g silicon dioxide powder, and 2.7g urea in 8mL deionized water to form a first solution;

[0061] (2) Add 8 mL of ethanol to the first solution, and magnetically stir for 20 min at room temperature to form a suspension;

[0062] (3) Add 4mL of 0.2mol / L nickel nitrate solution to the suspension, then sonicate and stir for 5h;

[0063] (4) Transfer the stirred solution in (3) into a polytetrafluoroethylene liner, and put it into a high-pressure reactor for 30 hours at 200°C;

[0064] (5) Centrifuge the mixed solution obtained after hydrothermal treatment in (4) at 8000 r / min, and wash the obtained precipitate three times with water and ethanol;

[0065] (6) drying the precipitate obtained in (5) at 80 °C overni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com