Method for preparing metal matrix composites by pulsed electric field assisted vacuum sheath rolling

A pulsed electric field, composite material technology, applied in the field of iron, magnesium, copper, titanium-based composite materials sintered, graphene or carbon fiber particle reinforcement phase aluminum field, can solve the wetting difficulty, reinforcement phase such as ceramic particles and metal matrix materialization Due to the large difference, the temperature and holding time are difficult to meet the sintering standards, etc., to achieve excellent comprehensive performance, improve sintering efficiency, and reduce deformation stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

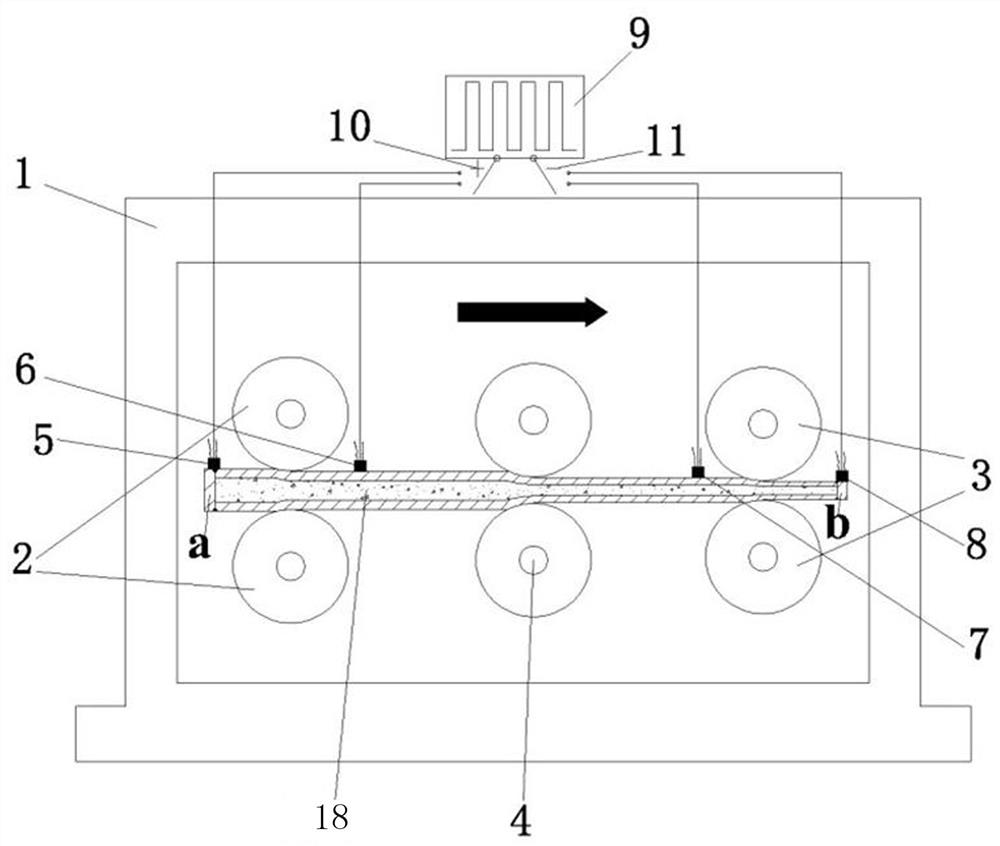

[0047] Preparation of B based on spark plasma sintering and vacuum sheath rolling 4 The method for C particle reinforced aluminum matrix composite material, comprises the steps:

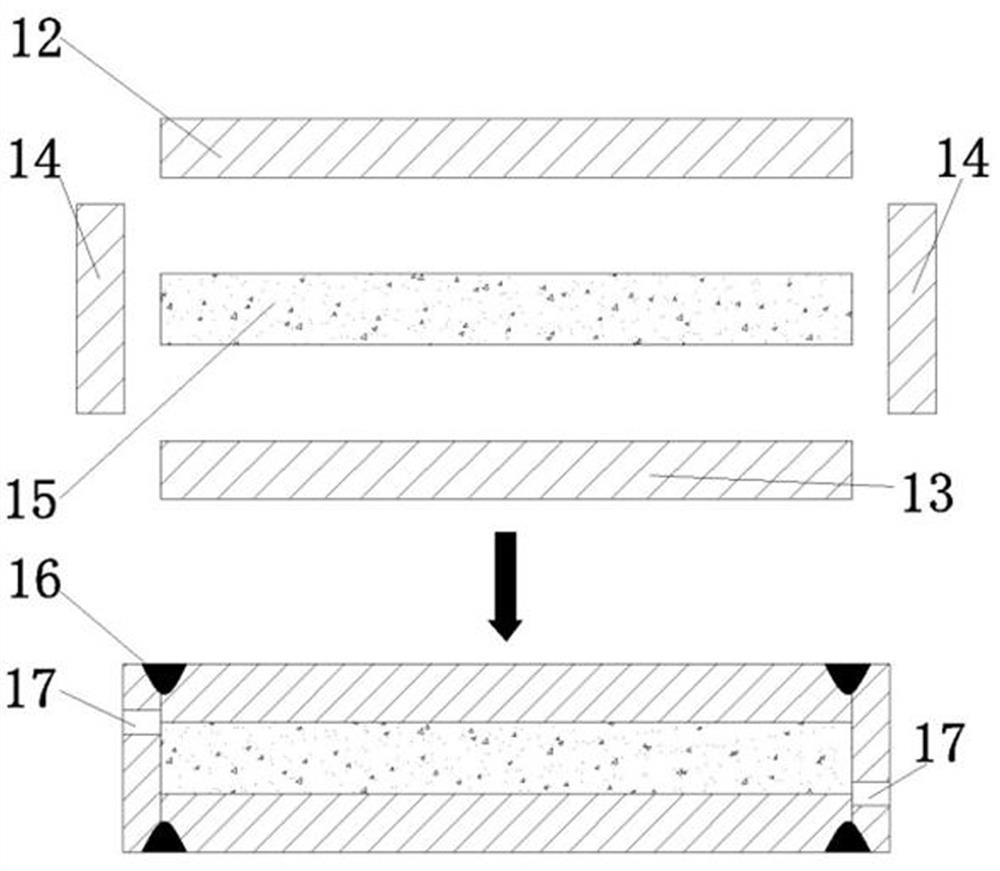

[0048] 1. Prepare the package

[0049] a. Will contain 15vol% B 4 Add aluminum-based powder of C ceramic particles (10~70μm) into a heating furnace filled with inert gas, heat to 500°C, dry and degas at high temperature for 2h, vacuum ball mill at 300rpm for 1h, and roll into 997×60×1.5mm by powder rolling powder green body;

[0050] b. Cut the 2A50 aluminum alloy plate into 1000×63×2mm plates, use 10% sulfuric acid aqueous solution to corrode and clean the surface of the metal plate and the powder to be in contact, and then perform mechanical and sandpaper polishing to completely remove the surface oxide layer and expose the fresh metal on the surface, and Ensure the surface roughness is 40~110μm, then wash with alcohol and acetone solution several times to remove surface oil, after drying, apply...

Embodiment 2

[0059] A method for preparing a carbon nanotube fiber reinforced magnesium-based composite material based on spark plasma sintering and vacuum sheath rolling, comprising the following steps:

[0060] 1. Prepare the package

[0061] a. Add Al powder containing 2wt% carbon nanotubes into a heating furnace filled with inert gas, heat to 500°C, dry and degas at high temperature for 2 hours, vacuum ball mill at 300rpm for 2 hours, and roll the powder into 997×60×1.5mm powder green body;

[0062]b. Cut the 2A50 aluminum alloy plate into 1000×63×2mm plates, use 10% sulfuric acid aqueous solution to corrode and clean the surface of the metal plate and the powder to be in contact, and then perform mechanical and sandpaper polishing to completely remove the surface oxide layer and expose the fresh metal on the surface, and Ensure the surface roughness is 40~110μm, then wash with alcohol and acetone solution several times to remove surface oil, after drying, apply water glass and glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com