Catalyst and preparation method and application thereof

A catalyst and reaction technology, which is applied in the field of catalyst and its preparation, can solve the problems of difficulty in breaking the carbon-carbon single bond at the surface active site, low catalyst efficiency, slow kinetic process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a kind of preparation method of catalyst, comprises the following steps:

[0045] After the ethylene glycol aqueous solution, graphene oxide and chloroplatinic acid are first mixed, the pH value is adjusted to >7, and the first reduction reaction is carried out to obtain the first intermediate product system;

[0046] performing a second mixing of the first intermediate product system and a second reducing agent solution to perform a second reduction reaction to obtain the catalyst;

[0047] The second reducing agent in the second reducing agent solution includes ascorbic acid and / or formic acid;

[0048] The volume concentration of the ethylene glycol aqueous solution is 50%-75%.

[0049] In the present invention, unless otherwise specified, all preparation materials are commercially available products well known to those skilled in the art.

[0050] In the present invention, after the first mixing of ethylene glycol aqueous solution, graphene ...

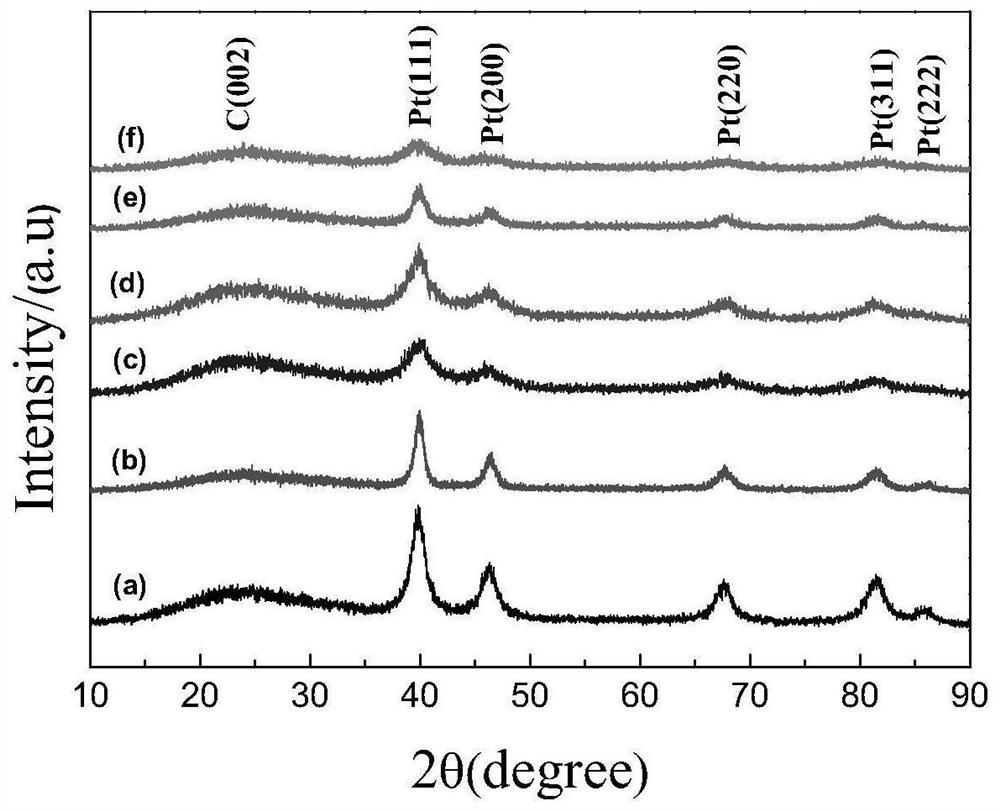

Embodiment 1

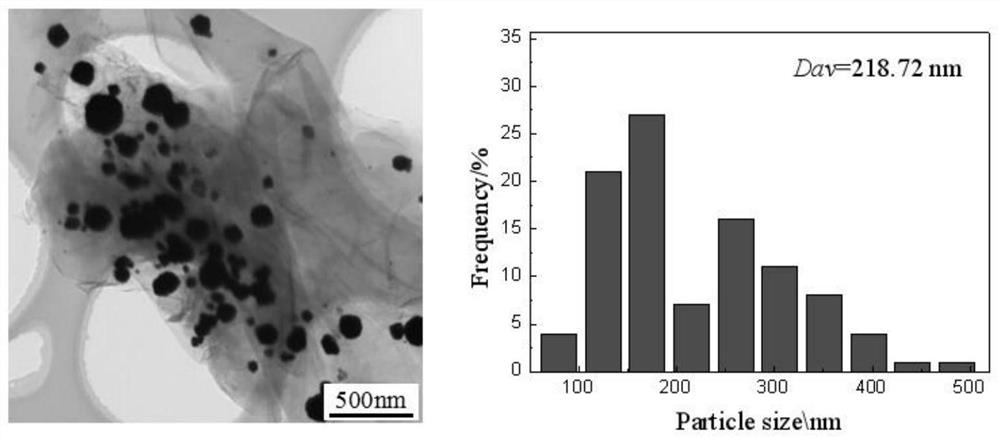

[0070] Mix 150 mg of graphene oxide and 50 mL of an ultrapure aqueous solution of ethylene glycol with a volume concentration of 50%, add 99.55 g of chloroplatinic acid hexahydrate under stirring conditions, and add sodium hydroxide until the pH value of the resulting mixed solution reaches 12 , continue to stir for 30 minutes, after ultrasonication for 30 minutes, stir at a speed of 10 rpm and heat up to 90°C, the heating time is 50min, after holding for 2h, add 20mL of formic acid solution with a volume concentration of 0.15%, react at 90°C for 6h, continue Stir and naturally cool to room temperature, wash with 2L ultrapure water, filter, vacuum dry (the temperature of the vacuum drying is 60°C, and the time is 12h), grind to obtain a catalyst (the particle size of Pt is 3.06nm, denoted as Pt / RGO EG-50 ).

Embodiment 2

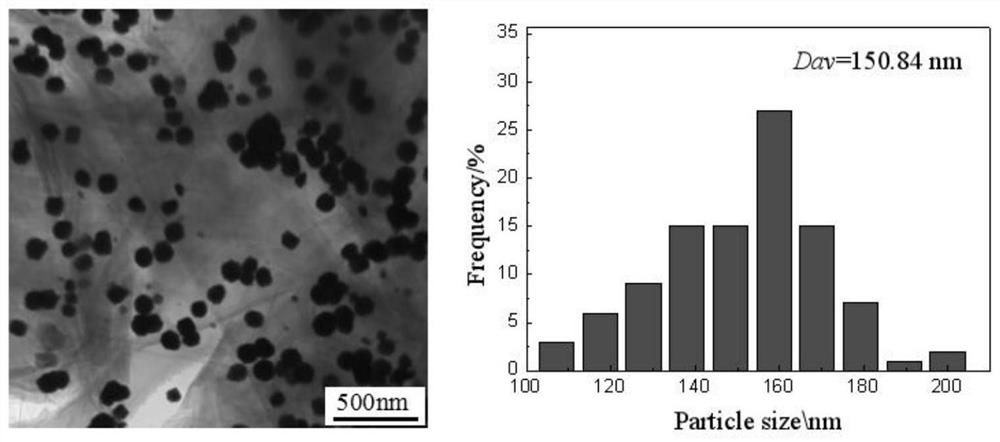

[0072] Preparation process with reference to Example 1, the only difference is that the volume concentration of the ultrapure aqueous solution of ethylene glycol is 66%, and the catalyst (Pt particle diameter is 2.48nm, denoted as Pt / RGO EG-66 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com