Method for treating COD(chemical oxygen demand) of high-salinity wastewater by utilizing compound microbial preparation and compound microbial preparation

A technology for complex microorganisms and high-salt wastewater, applied in the direction of microorganism-based methods, biological water/sewage treatment, biochemical equipment and methods, etc., can solve the effects of affecting the effect of biochemical treatment, easy to generate a large amount of sediment, low oxygenation efficiency, etc. problem, to achieve the effect of improving the COD removal rate, reducing the toxic effect of the bacteria, and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

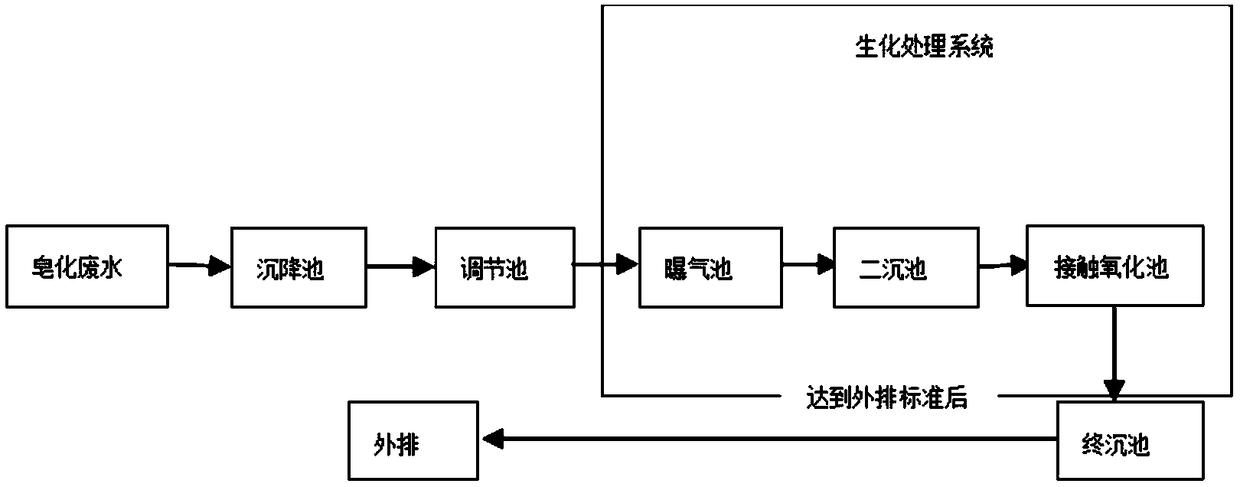

Method used

Image

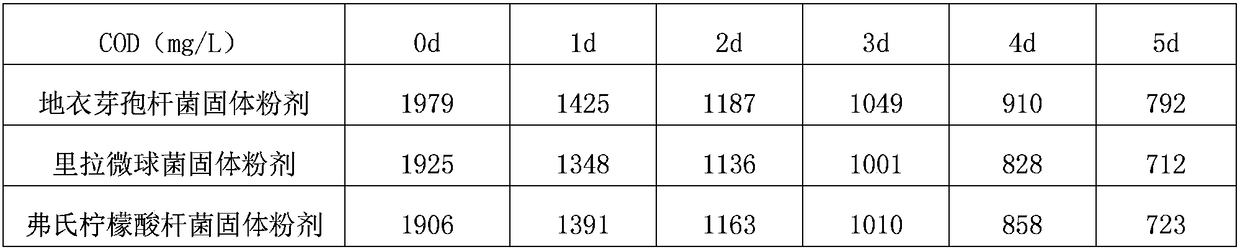

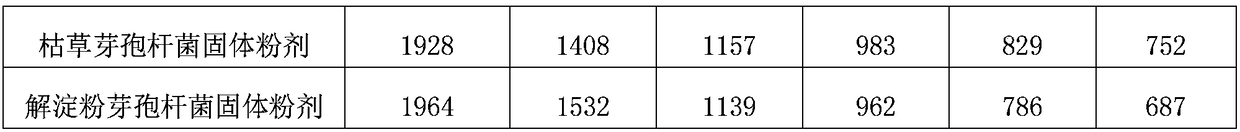

Examples

Embodiment 1

[0044] A compound microbial preparation for auxiliary treatment of high-salt wastewater COD, comprising 15% solid powder of Bacillus licheniformis, 15% solid powder of Micrococcus lira, 20% solid powder of Citrobacter freundii, and solid powder of Bacillus subtilis by weight percentage Powder 25%, and Bacillus amyloliquefaciens solid powder 25%.

[0045] Wherein, the viable bacterial concentration of above-mentioned bacillus licheniformis solid powder is 5 * 10 10 CFU / g, the live bacteria concentration of Micrococcus lira solid powder is 5×10 8 CFU / g, the live bacteria concentration of Citrobacter freundii solid powder is 5×10 10 CFU / g, the live bacteria concentration of Bacillus subtilis solid powder is 5×10 10 CFU / g, the live bacteria concentration of Bacillus amyloliquefaciens solid powder is 5×10 10 CFU / g.

[0046] The preparation method of above-mentioned composite microbial preparation, the steps are as follows:

[0047] (1) Solid slant culture: Inoculate Bacillus l...

Embodiment 2

[0058] A compound microbial preparation for auxiliary treatment of high-salt wastewater COD, comprising 18% solid powder of Bacillus licheniformis, 18% solid powder of Micrococcus lira, 20% solid powder of Citrobacter freundii, and solid powder of Bacillus subtilis by weight percentage Powder 22%, and Bacillus amyloliquefaciens solid powder 22%.

[0059] Wherein, the viable bacterial concentration of above-mentioned bacillus licheniformis solid powder is 4 * 10 10 CFU / g, the live bacteria concentration of Micrococcus lira solid powder is 5×10 8 CFU / g, the live bacteria concentration of Citrobacter freundii solid powder is 6×10 10 CFU / g, the live bacteria concentration of Bacillus subtilis solid powder is 5×10 10 CFU / g, the live bacterial concentration of Bacillus amyloliquefaciens solid powder is 4×10 10 CFU / g.

[0060] The preparation method of above-mentioned composite microbial preparation, the steps are as follows:

[0061] (1) Solid slant culture: Inoculate Bacillus ...

Embodiment 3

[0072] A kind of composite microbial preparation for auxiliary treatment of high-salt wastewater COD, with embodiment 1, the difference is, by weight percentage, comprises bacillus licheniformis solid powder 20%, micrococcus lira solid powder 21%, Freund's citric acid Bacillus solid powder 16%, Bacillus subtilis solid powder 21%, and Bacillus amyloliquefaciens solid powder 22%.

[0073] Preferably according to the present invention, the viable bacteria concentration of above-mentioned bacillus licheniformis solid powder is 5 * 10 10 CFU / g, the live bacteria concentration of Micrococcus lira solid powder is 6×10 8 CFU / g, the live bacteria concentration of Citrobacter freundii solid powder is 5×10 10 CFU / g, the live bacteria concentration of Bacillus subtilis solid powder is 4×10 10 CFU / g, the live bacteria concentration of Bacillus amyloliquefaciens solid powder is 5×10 10 CFU / g.

[0074] The preparation method of above-mentioned composite microbial preparation, the steps a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com