Preparation method of cationic polymer acid solution retarding agent

A cationic polymer and retarder technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult pumping, unstable foam acid, easy rupture, etc. The effect of the slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

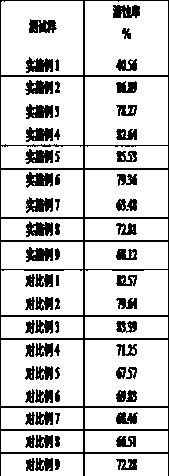

Examples

Embodiment 1

[0009] Weigh 0.9 parts by weight of initiator azobisisobutylamidine hydrochloride, dissolve it in 20 parts by weight of deionized water, and set aside; mix 8 parts of methacryloyloxyethyltrimethylammonium chloride, 4 parts of Polyethylene glycol and 180 parts by weight of deionized water are placed in a reaction kettle, and half of the above-mentioned prepared initiator is added and then magnetically stirred for 2 hours to fully dissolve; the solution is heated to 70°C, and 24 parts by weight of Dicyclopentadiene dioxide, 5 parts by weight of hexadecyl dimethyl allyl ammonium chloride, ultrasonic vibration 30min, add the remaining half of the initiator, dropwise within 80min, after mixing evenly, under the action of a magnetic field Purge with argon gas for 1~2h, raise the temperature to 85°C and react at constant temperature for 2h, then lower the temperature to 65~70°C, add 16 parts of nano-silica / cellulose composite materials and continue the heat preservation reaction for 2...

Embodiment 2

[0013] It is exactly the same as Example 1, except that 10 parts of methacryloyloxyethyltrimethylammonium chloride and 20 parts by weight of dicyclopentadiene dioxide are added.

Embodiment 3

[0015] It is exactly the same as Example 1, except that 7 parts of methacryloyloxyethyltrimethylammonium chloride and 28 parts by weight of dicyclopentadiene dioxide are added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com