Four-stage filtration system for removing mixed oil meal and working method of four-stage filtration system

A four-stage filtration and mixed oil technology, which is applied in the direction of fat oil/fat refining, the device where the axial direction of the swirl flow can be reversed, and fat generation, can solve the problem of affecting the quality of crude oil products, reducing the heat transfer rate of equipment, and mixing oil Color deepening and other problems, to achieve the effect of saving steam consumption, improving the heat exchange rate of equipment, and reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

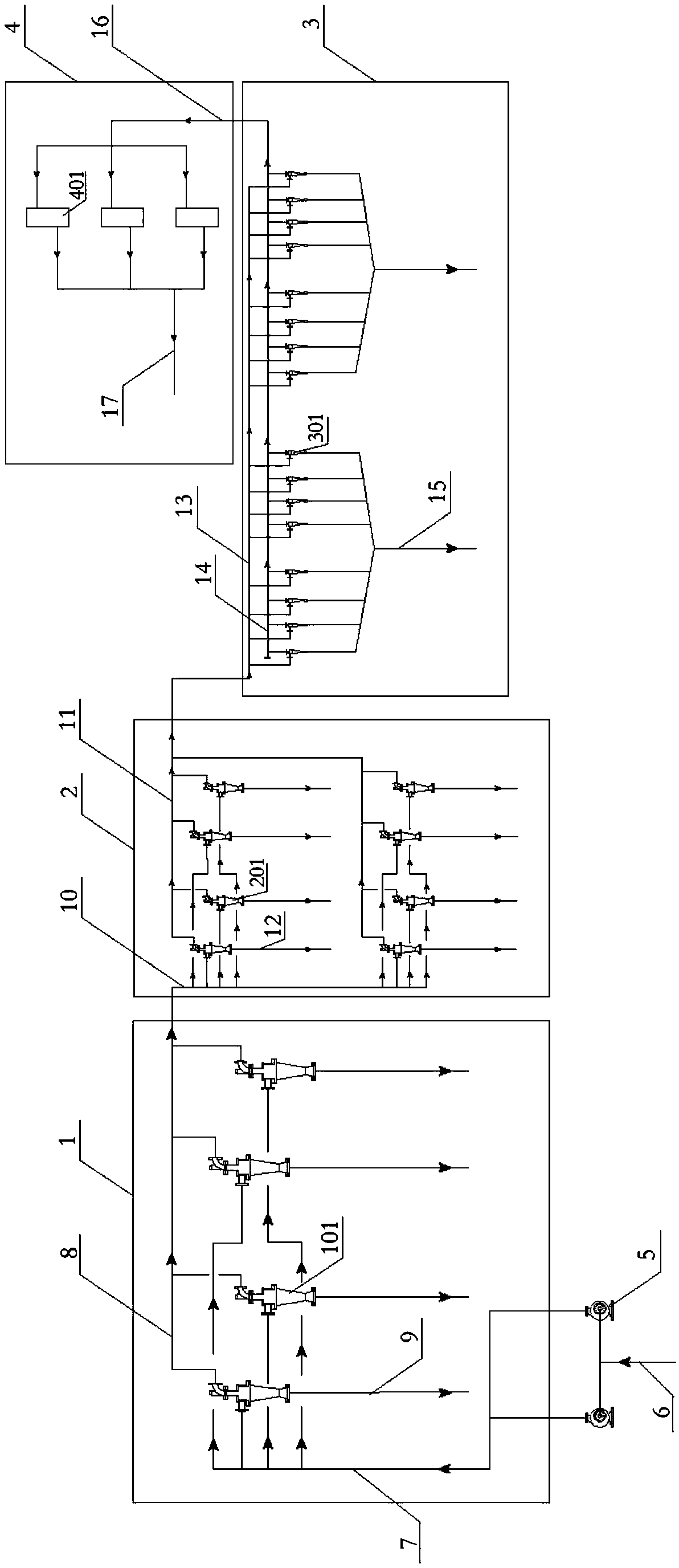

[0023] A four-stage filtration system for removing meal powder in mixed oil, including a first-stage hydrocyclone group 1, a second-stage hydrocyclone group 2, a third-stage hydrocyclone group 3, and a self-cleaning scraper filter Group 4, extractor connecting pipeline 6 and mixed oil output pipeline 17, said extractor connecting pipeline 6 communicates with primary feed pipeline 7 in primary hydrocyclone group 1, said primary inlet The feed pipeline 7 communicates with the feed port of the primary hydrocyclone 101 through the feed branch, and the mixed oil outlet at the top of the primary hydrocyclone 101 is connected with the primary discharge pipe through the discharge branch. Road 8 communicates, and the primary discharge pipeline 8 communicates with the secondary feed pipeline 10 in the secondary hydrocyclone group 2, and the secondary feed pipeline 10 communicates with the secondary feed pipeline 10 through the feed branch. The feed port of the hydrocyclone 201 is commun...

Embodiment 2

[0025] A four-stage filtration system for removing meal powder in mixed oil, including a first-stage hydrocyclone group 1, a second-stage hydrocyclone group 2, a third-stage hydrocyclone group 3, and a self-cleaning scraper filter Group 4, extractor connecting pipeline 6 and mixed oil output pipeline 17, said primary hydrocyclone group 1 is provided with 4 primary hydrocyclones 101; said secondary hydrocyclone group 2 There are 8 secondary hydrocyclones 201 in it; 16 tertiary hydrocyclones 301 are provided in the tertiary hydrocyclone group 3; 3 hydrocyclones 301 are provided in the self-cleaning scraper filter group 4 A self-cleaning scraper filter 401;

[0026] The extractor connection pipeline 6 communicates with the primary feed pipeline 7 in the primary hydrocyclone group 1, and the primary feed pipeline 7 communicates with the primary hydrocyclone 101 through a feed branch. The feed port of the primary hydrocyclone 101 is connected to the outlet of the mixed oil at the ...

Embodiment 3

[0028] A four-stage filtration system for removing meal powder in mixed oil, including a first-stage hydrocyclone group 1, a second-stage hydrocyclone group 2, a third-stage hydrocyclone group 3, and a self-cleaning scraper filter Group 4, extractor connecting pipeline 6 and mixed oil output pipeline 17, said primary hydrocyclone group 1 is provided with 4 primary hydrocyclones 101; said secondary hydrocyclone group 2 There are 8 secondary hydrocyclones 201 in it; 16 tertiary hydrocyclones 301 are provided in the tertiary hydrocyclone group 3; 3 hydrocyclones 301 are provided in the self-cleaning scraper filter group 4 A self-cleaning scraper filter 401;

[0029]A mixed oil pump is provided on the connecting pipeline 6 of the extractor, and the connecting pipeline 6 of the extractor communicates with the primary feed pipeline 7 in the primary hydrocyclone group 1, and the primary feed pipeline 7 communicates with the feed inlet of the primary hydrocyclone 101 through the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com