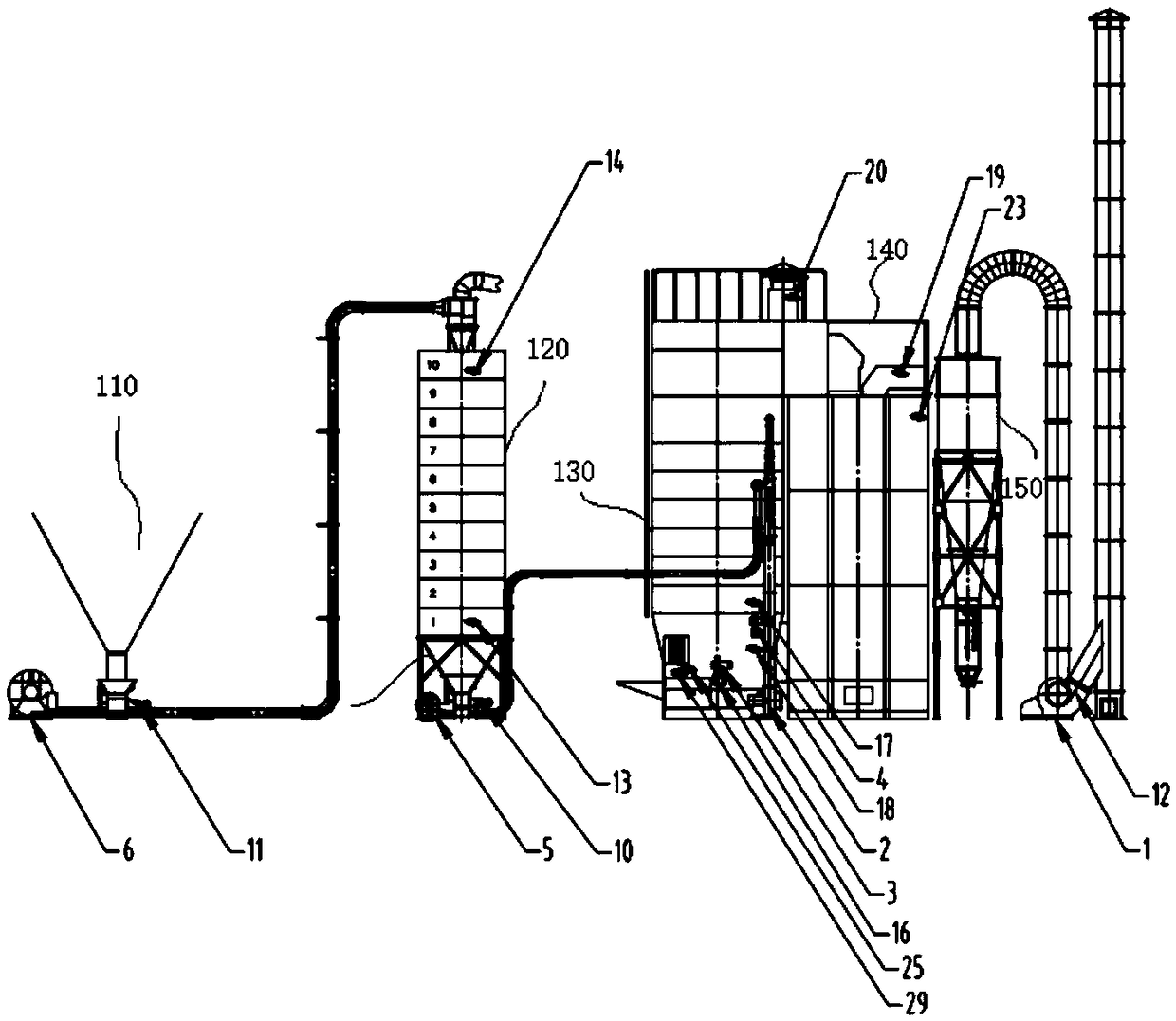

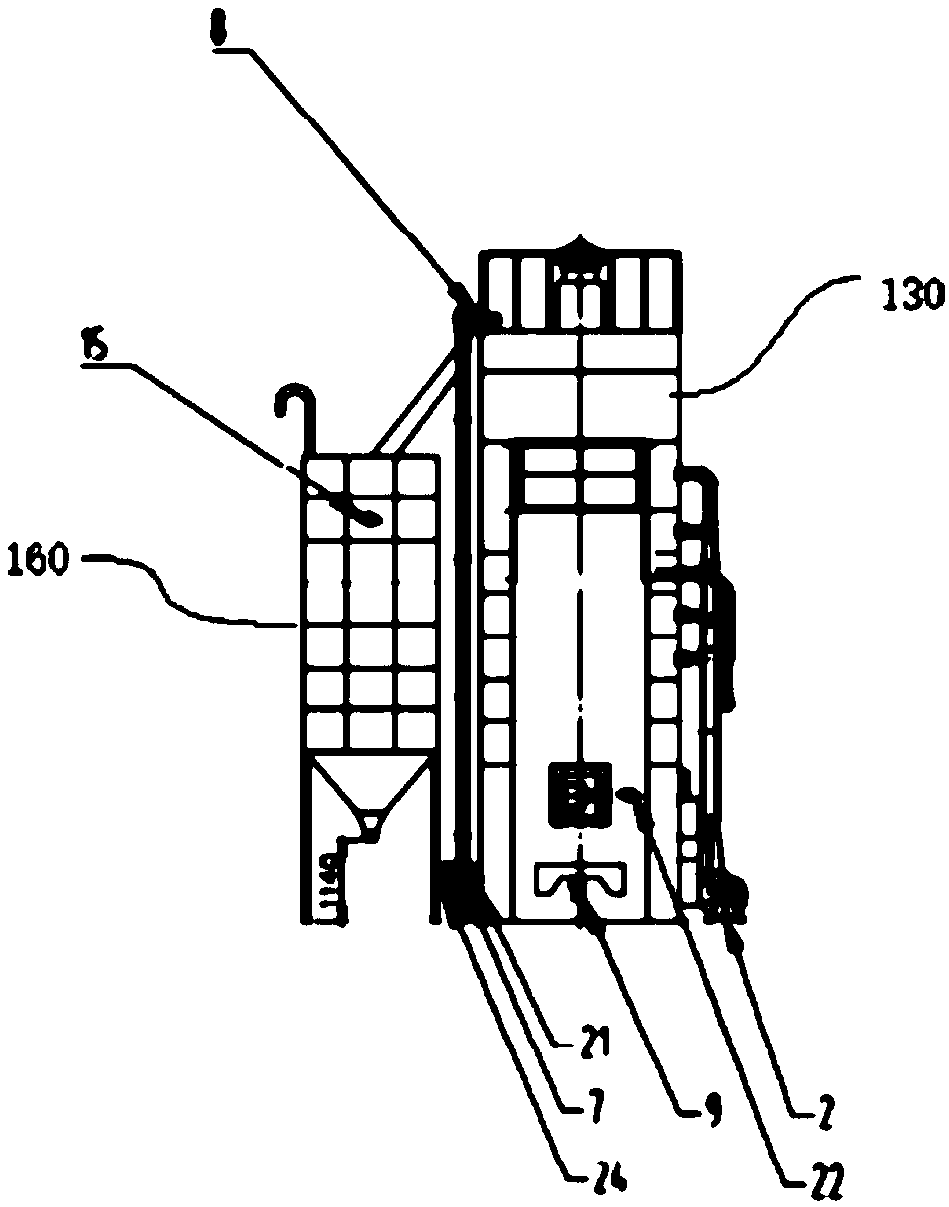

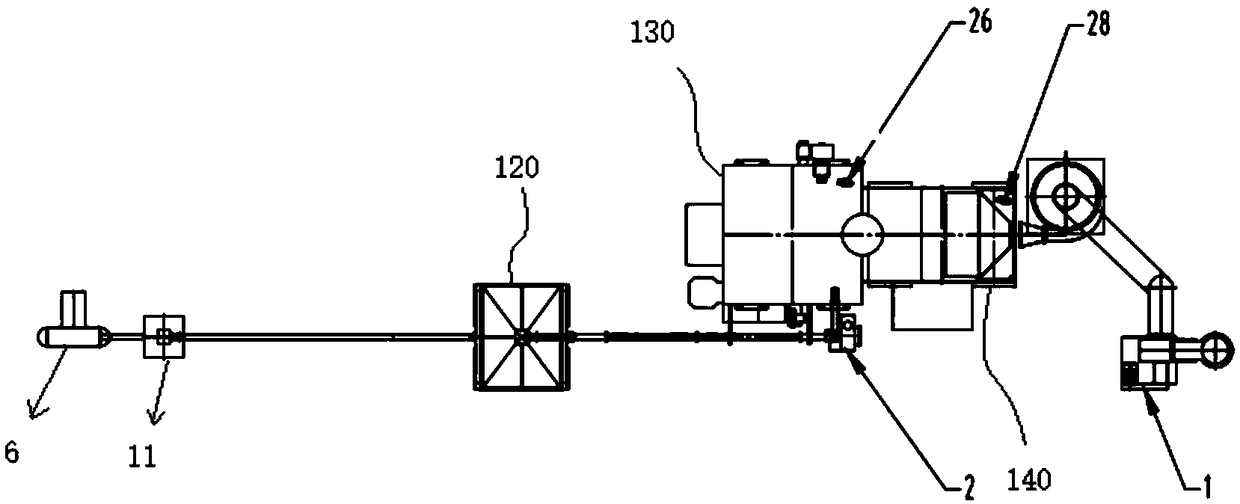

Electric control system of air heating furnace and control method

An electronic control system and control method technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as unstable firepower, incomplete combustion of fuel, and gas leakage, so as to improve sensitivity and Accuracy, good stability and accuracy, no black smoke emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The following description serves to disclose the invention to enable those skilled in the art to carry out the invention. The preferred embodiments described below are only examples, and those skilled in the art can conceive of other obvious modifications. The basic principles of the present invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and other technical solutions without departing from the spirit and scope of the present invention.

[0072] It can be understood that the term "a" should be understood as "at least one" or "one or more", that is, in one embodiment, the number of an element can be one, while in another embodiment, the number of the element The number can be multiple, and the term "one" cannot be understood as a limitation on the number; the term "connection" should be understood as "wireless connection" or "wired connection", and it can be "direct connection" or "indirect connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com