Solar energy measuring material heat conductivity coefficient experimental device and measuring method thereof

A technology of thermal conductivity and solar energy, applied in the field of physical experiment instruments, can solve problems such as inconvenient operation, inconsistent timing of timers, and influence on experimental measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

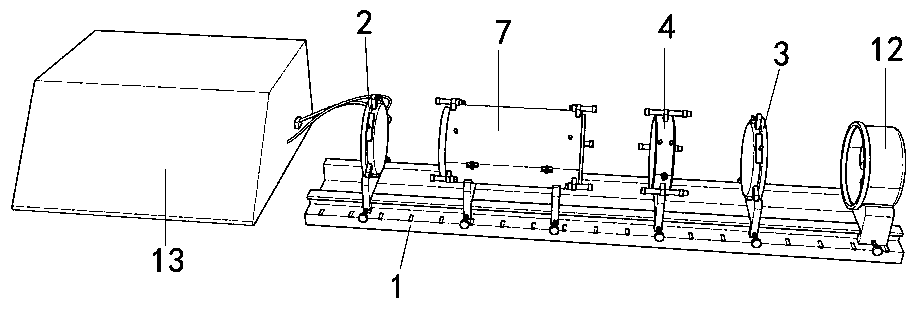

[0090] Concrete embodiment: the concrete steps of bad conductor thermal conductivity measuring method are as follows:

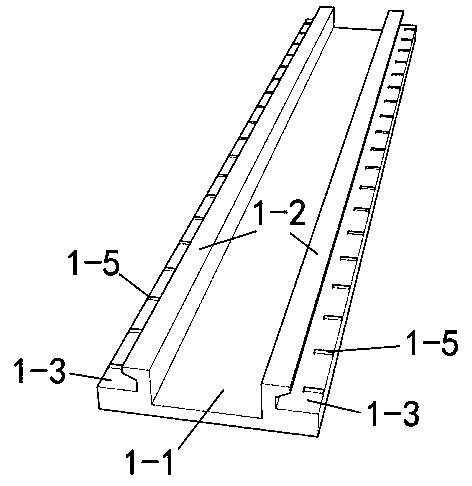

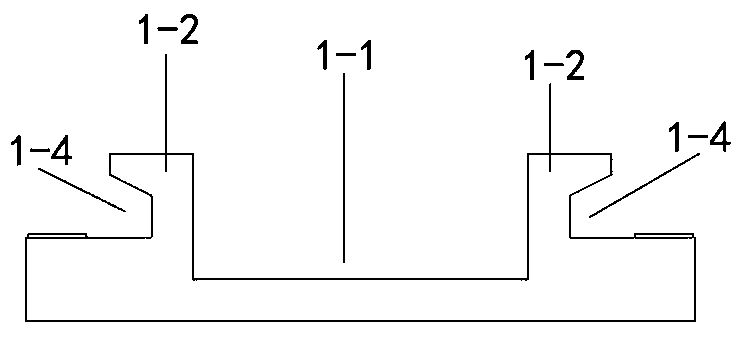

[0091] (1) Insert the heating plate rack 2, the bad conductor sample rack 4, the cooling plate rack 3, and the cooling fan 12 on the slide rail 1 in sequence from left to right; fasten the sliding seat on the heating plate rack 2 with the bolt 2- 5. Tighten it inward and fix it with the slide rail 1; install the heating plate 8 in the disc installation cavity 2-11 on the heating plate frame 2, and tighten it inward through the disc fastening bolt 2-6;

[0092] (2) Push the bad conductor sample rack 4 to the side of the heating tray 2, open the insulation sleeve 4-2 on the bad conductor sample rack 4 after approaching, and put the bad conductor sample 5 into the hollow circle 2 4-4 , close the thermal insulation sleeve 4-2, tighten and fix the front side interface 4-9 of the thermal insulation sleeve 4-2 by bolts; fine-tune the bad conductor sample holder 4 so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com