Preparation method of graphene-coated micron silicon with core-shell structure

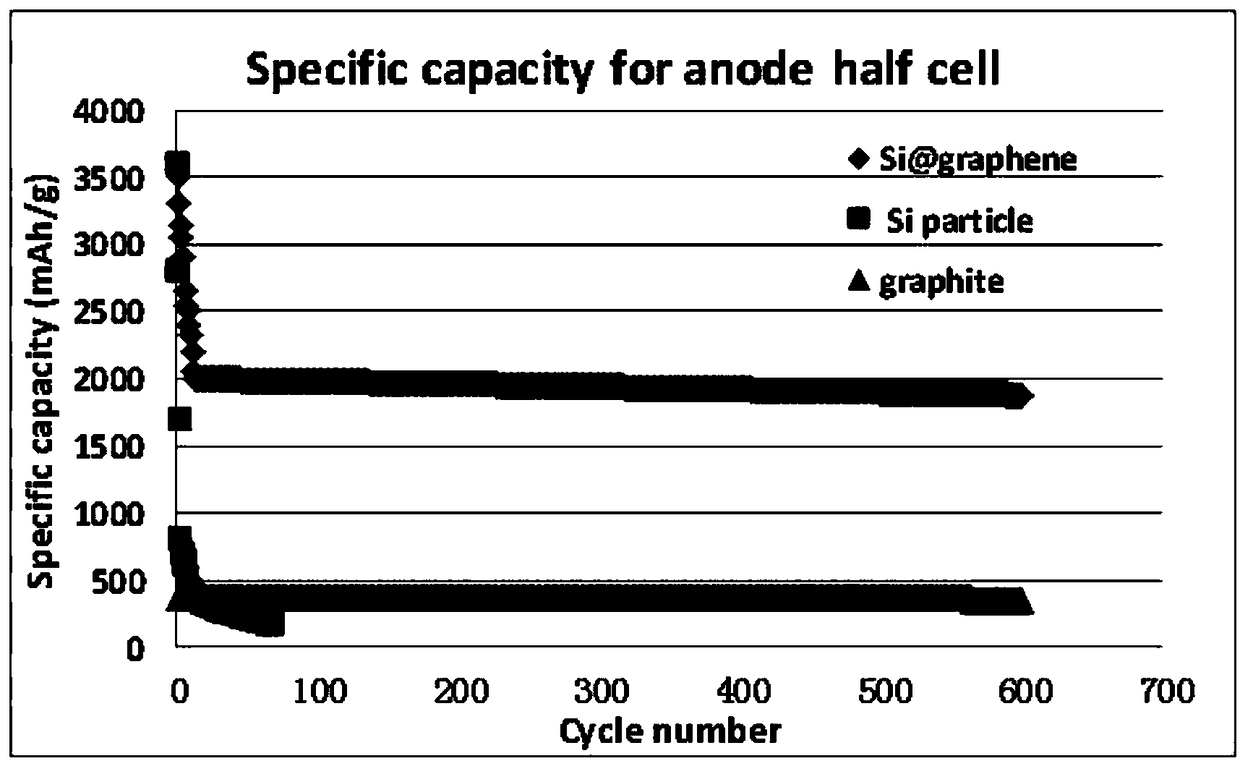

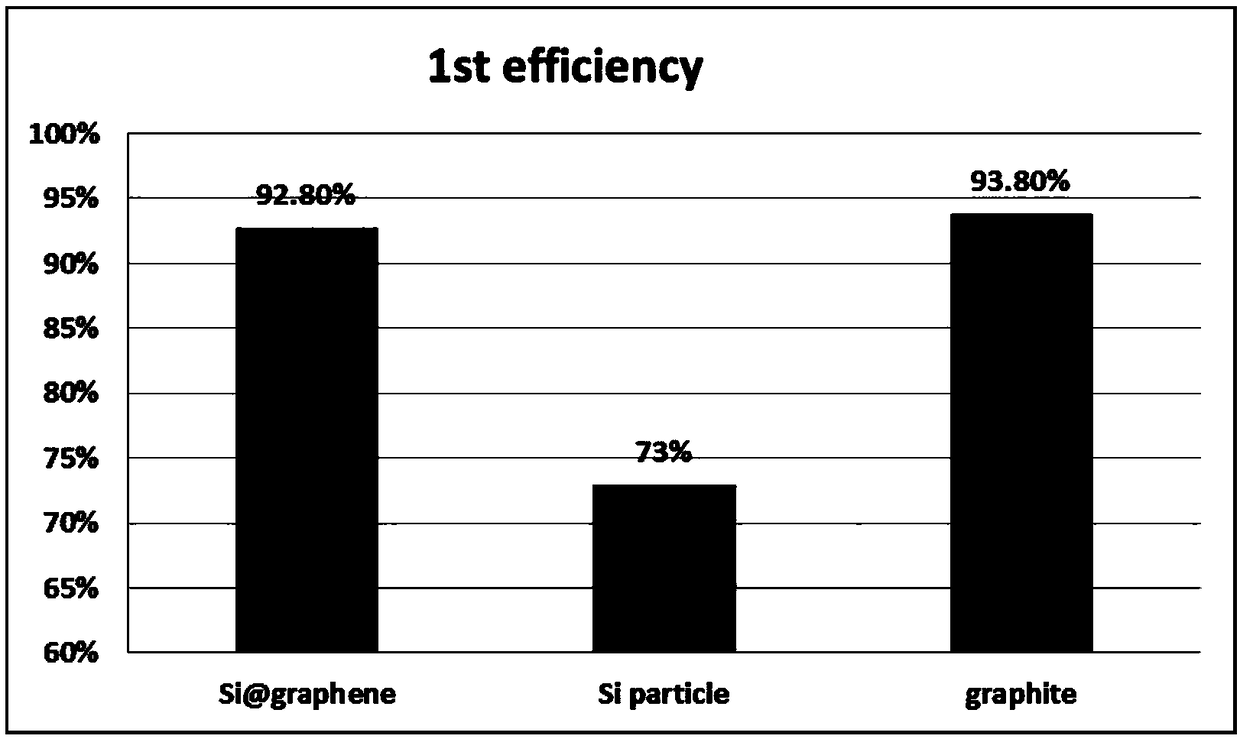

A graphene-coated, core-shell structure technology, applied in the direction of structural parts, active material electrodes, electrical components, etc., can solve the problems of poor power performance, low initial efficiency, large volume expansion, etc., to avoid continuous contact and low price , the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of core-shell structure graphene coating micron silicon, comprises the following steps:

[0035] Step 1, growing SiO on the surface of micron silicon 2 layer, resulting in SiO 2 Composite material coated with micron silicon, the specific operation is as follows:

[0036] 1) Take 28g of silicon particles and disperse them in 1000g of deionized water, and stir them mechanically for 20min to form an aqueous solution containing silicon powder;

[0037] 2) Take 10g Na 2 SiO 3 Dissolve in an aqueous solution containing silicon powder, heat it in a water bath at 85°C, and then slowly introduce CO while stirring 2 Gas, control the flow rate of the gas to 8m / s, react for 60min, and coat a uniform layer of SiO on the surface of micron silicon 2 layer;

[0038] 3) step 2) gained solution is carried out suction filtration, obtains filtrate, removes Na with deionized water cleaning then 2 SiO 3 , and SiO was obtain...

Embodiment 2

[0043] The present embodiment provides a kind of preparation method of core-shell structure graphene coating micron silicon, comprises the following steps:

[0044] Step 1, growing SiO on the surface of micron silicon 2 layer, resulting in SiO 2 Composite material coated with micron silicon, the specific operation is as follows:

[0045] 1) Take 20g of silicon particles and disperse them in 1000g of deionized water, and stir them mechanically for 10min to form an aqueous solution containing silicon powder;

[0046] 2) Take 10g Na 2 SiO 3Dissolve in an aqueous solution containing silicon powder, heat it in a water bath at 70°C, and then slowly introduce CO while stirring 2 Gas, control the flow rate of the gas to 10m / s, react for 45min, and coat a uniform layer of SiO on the surface of micron silicon 2 layer;

[0047] 3) step 2) gained solution is carried out suction filtration, obtains filtrate, removes Na with deionized water cleaning then 2 SiO 3 , and SiO was obtain...

Embodiment 3

[0052] The present embodiment provides a kind of preparation method of core-shell structure graphene coating micron silicon, comprises the following steps:

[0053] Step 1, growing SiO on the surface of micron silicon 2 layer, resulting in SiO 2 Composite material coated with micron silicon, the specific operation is as follows:

[0054] 1) Take 32g of silicon particles and disperse them in 1000g of deionized water, and stir them mechanically for 30min to form an aqueous solution containing silicon powder;

[0055] 2) Take 12g Na 2 SiO 3 Dissolve it in an aqueous solution containing silicon powder, heat it in a water bath at 100°C, and then slowly introduce CO while stirring 2 Gas, control the flow rate of the gas to 5m / s, react for 90min, and coat a uniform layer of SiO on the surface of micron silicon 2 layer;

[0056] 3) step 2) gained solution is carried out suction filtration, obtains filtrate, removes Na with deionized water cleaning then 2 SiO 3 , and SiO was ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com