Void-containing heat-shrinkable polyester-based film

A heat-shrinking, film technology, applied in rigid containers, thin material processing, flexible coverings, etc., can solve the problems of high light transmittance, uncomfortable content protection, etc., to achieve excellent appearance, good shrinkage processability, amorphous The effect of small difference in raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

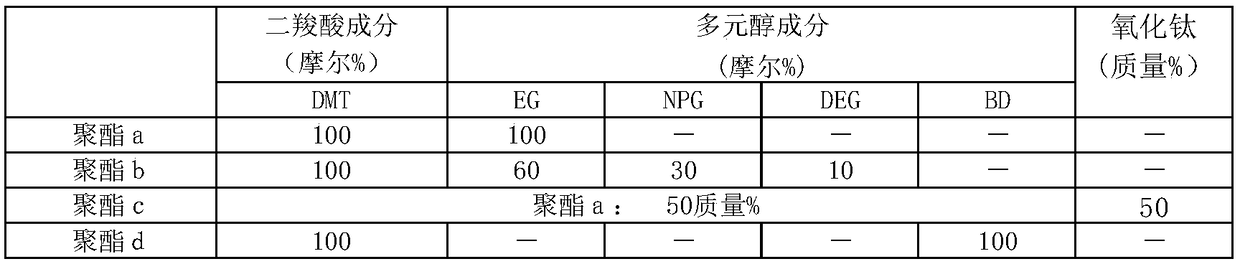

Method used

Image

Examples

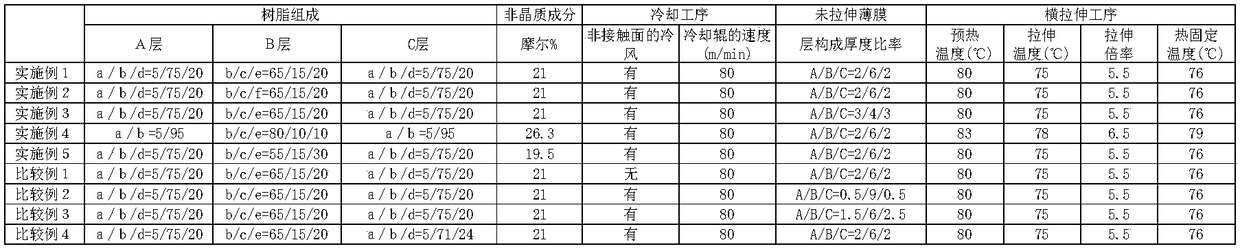

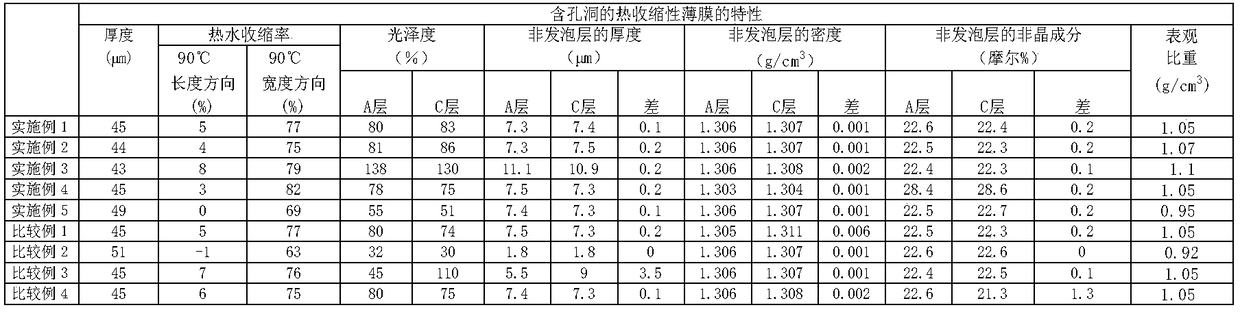

Embodiment 1

[0173] 5% by weight of polyester a, 75% by weight of polyester b, and 20% by weight of polyester c are mixed as layer A, and 65% by weight of polyester b and 15% by weight of polyester c are mixed as layer B. , raw material e 20% by weight of polyester, as layer C mixed with 5% by weight of polyester a, 75% by weight of polyester b, and 20% by weight of polyester c, layer A and layer C were heated at 265°C Melt, melt the B layer at 280°C, and co-extrude from the T die in such a way that the layer thickness ratio becomes A layer / B layer / C layer = 20 / 60 / 20. cold to obtain an unstretched multilayer film with a thickness of 200 μm. The temperature of the cooling roll at this time was 25 degreeC, and it contacted with layer A. To the layer C opposite to the cooling roll, a multiduct was used to blow cold air at 10° C. at a rate of 8 m / S at the center and at 10 m / S at the ends.

[0174] This unstretched film was preheated until the film temperature became 80° C., and then stretche...

Embodiment 2

[0177] Except having changed the raw material e of B layer into raw material f, the heat-shrinkable polyester film containing a hole was obtained by the method similar to Example 1. Table 3 shows the evaluation results of the obtained film. A film with good shrinkage processability was obtained.

Embodiment 3

[0179] The discharge rate of the extruder was changed, and co-extrusion was carried out from the T die head so that the layer thickness ratio became A layer / B layer / A layer=30 / 40 / 30, and it was quenched on a cooling (chilling) roll, and changed to A void-containing heat-shrinkable polyester film was obtained in the same manner as in Example 1 except for an unstretched multilayer film having a thickness of 200 μm. Table 3 shows the evaluation results of the obtained film. Glossiness and apparent specific gravity were increased, but a film with good shrinkage processability was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| shrinkage stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com