Activation device for adjusting throughput of ball mill

A technology of adjusting device and throughput, applied in grain processing and other directions, can solve the problems of effectively adjusting the size of the opening of the activated plate unit, unable to effectively control the residence time of materials, affecting the crushing and grinding efficiency of the grinding body, and improving the crushing and grinding efficiency. Grinding efficiency, increasing the chance of crushing and grinding, the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments.

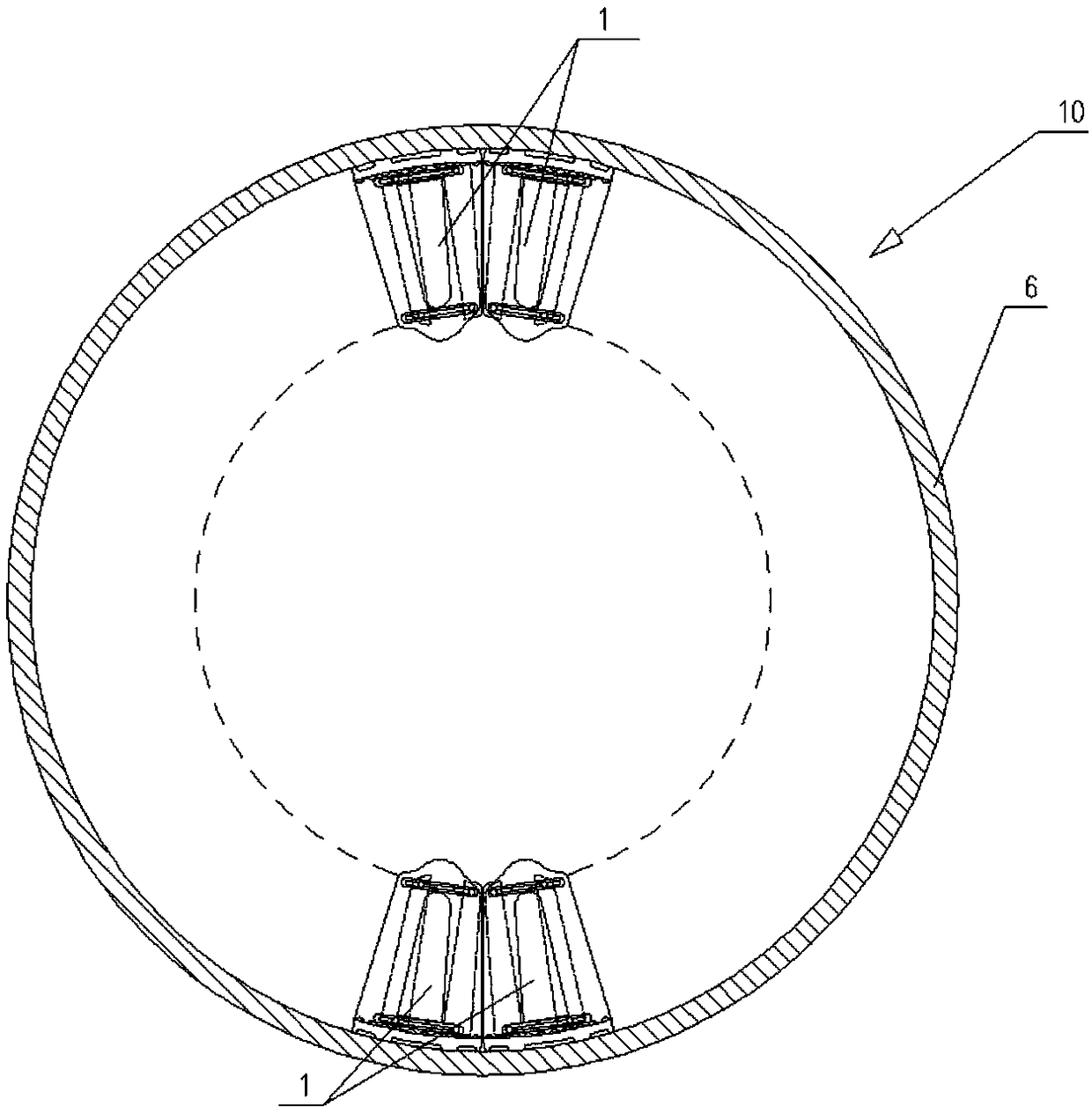

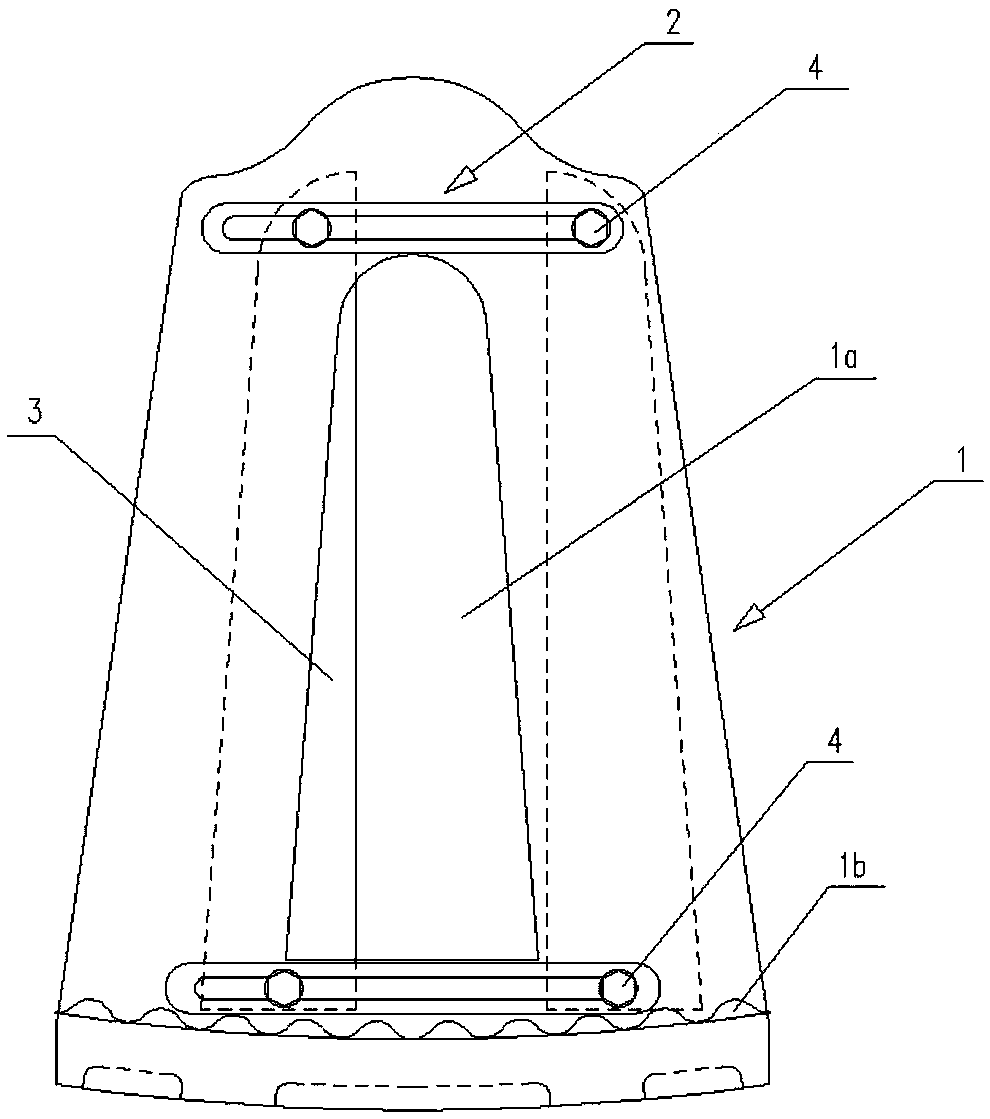

[0026] Such as figure 1 , figure 2 As shown, the present invention discloses an activation device 10 for adjusting the material throughput of a ball mill. The activation device 10 is composed of a plurality of activation plate units 1 with the same structure to form an annular plate, and the annular plate is perpendicular to the cylinder 6 The outer edge of the center line is fixed on the inner wall of the cylinder 6; each activation plate unit 1 includes: an opening 1a and a grinding body support 1b.

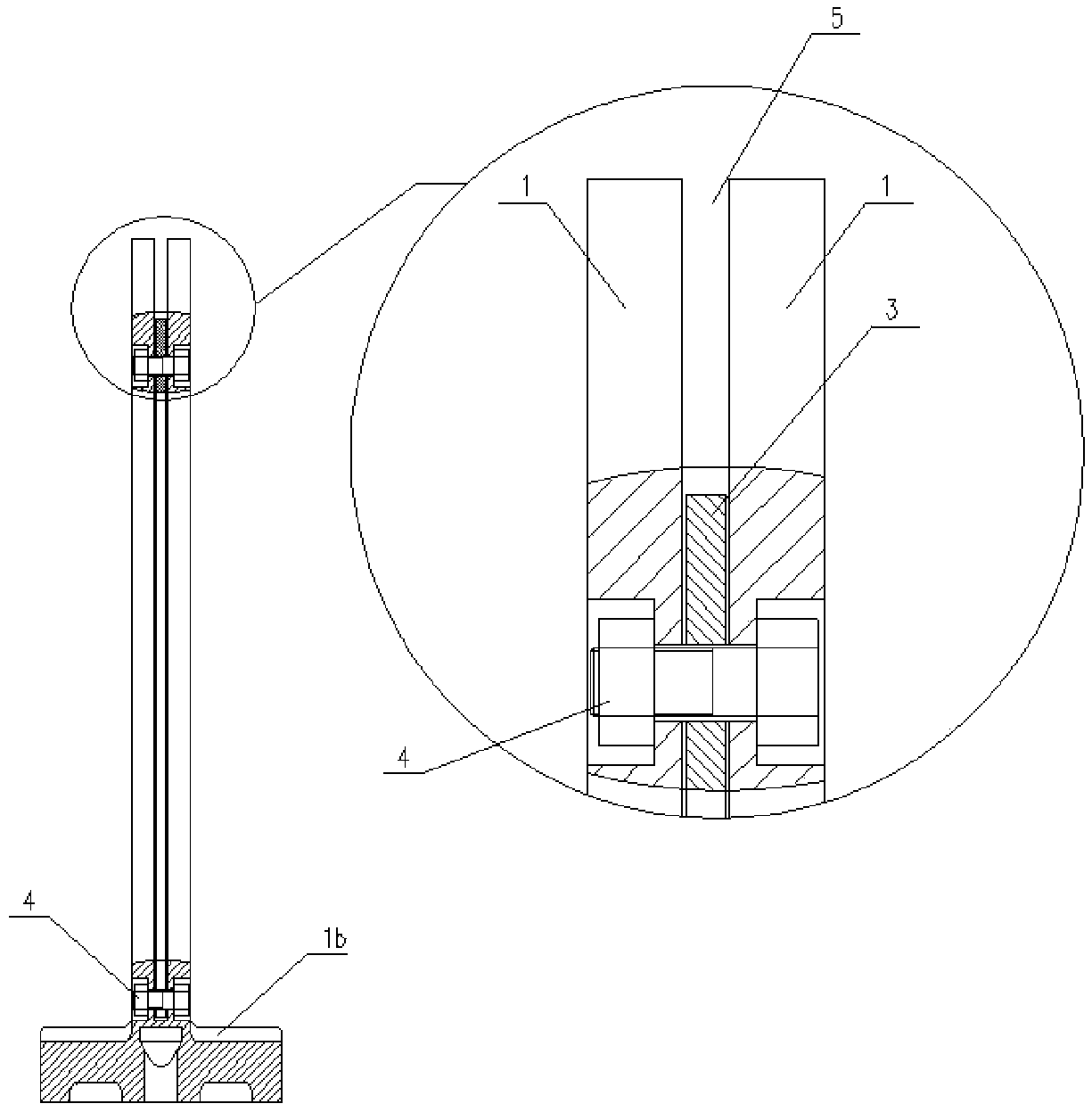

[0027] Such as figure 2 , image 3 As shown, between the two sides of the activation plate unit 1 is provided a U-shaped groove 5 penetrating left and right, and two baffle plates 3 are provided in the U-shaped groove 5, and the two baffle plates 3 are located in the open area....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com