Seedless preparation method of gold nanorods

A gold nanorod, seedless technology is applied in the field of one-step preparation of gold nanorods in aqueous phase without using a seed solution, which can solve the problem of many spherical particles, poor morphology uniformity of gold nanorods, and narrow adjustable range of longitudinal surface plasmon resonance absorption. and other problems, to achieve the effect of narrow half-peak width, uniform morphology, and short preparation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 180mg of cetyltrimethylammonium bromide and 35mg of sodium oleate, add 9.8mL of water, place in a 50°C water bath to dissolve completely, then cool down to 30°C.

[0030] (2) Add 360μL of 4mM AgNO to the above solution 3 solution. After standing for 15 min, add 200 μL of 25 mM HAuCl 4 solution and stirred for 50 min.

[0031] (3) Add 360 μL of 1M HCl solution to the above solution, and stir for 5 minutes.

[0032] (4) Quickly add 37.5 μL of 85.7 mM ascorbic acid solution and 7.5 μL of freshly prepared 10 mM NaBH to the above solution 4 The solution was stirred for 10 seconds and then allowed to stand for 5 hours, and purified by centrifugation to obtain the product.

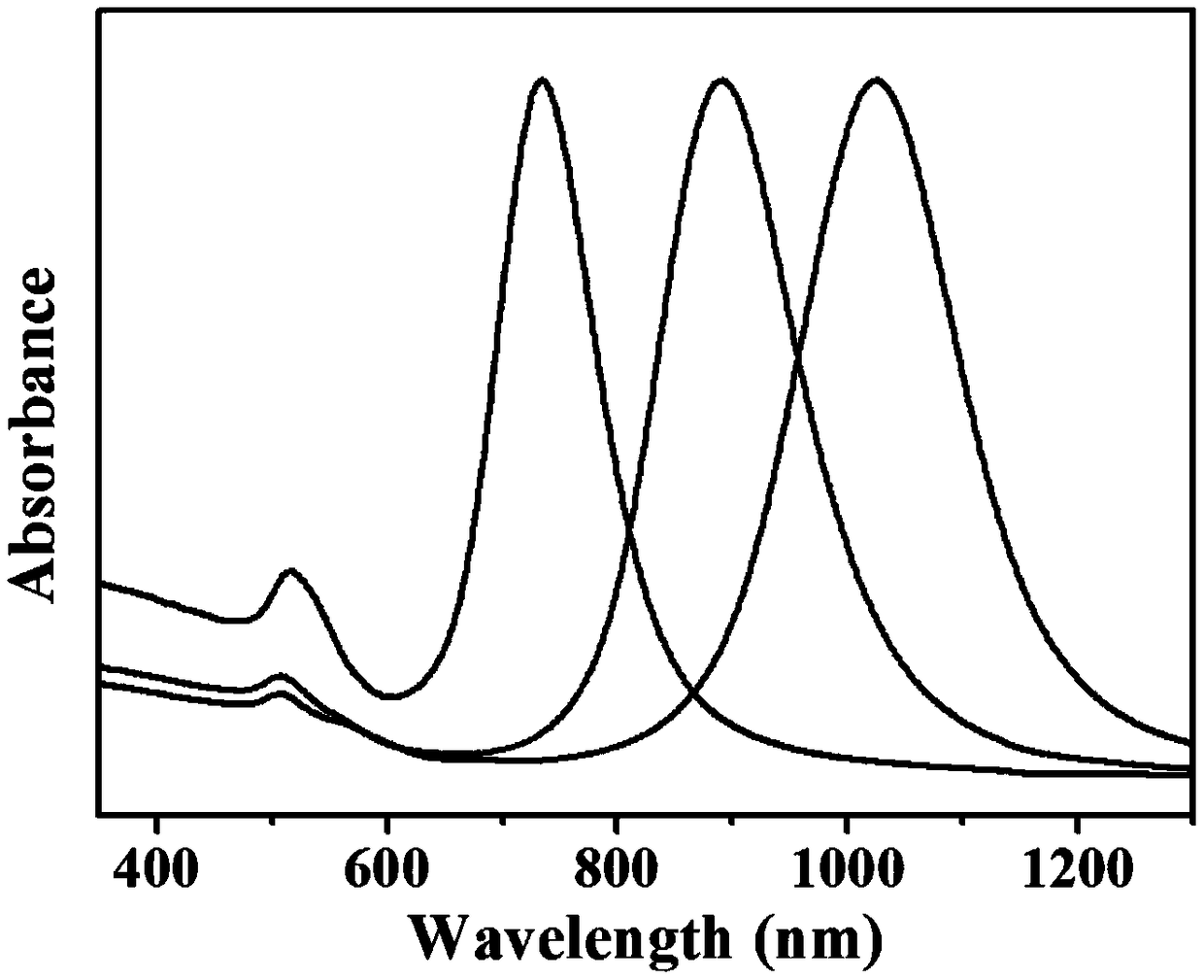

[0033] The experimental results show that the obtained gold nanorods have a size of 24.3±2.7nm×77.7±8.0nm, a maximum absorption peak position of 735nm, a half-maximum width of 106nm, uniform morphology, almost no spherical particles, and rod-shaped products>99.5%.

Embodiment 2

[0035] (1) Weigh 180mg of cetyltrimethylammonium bromide and 25mg of sodium oleate, add 9.8mL of water, place in a 50°C water bath to dissolve completely, and then cool down to 30°C.

[0036] (2) Add 360μL of 4mM AgNO to the above solution 3 solution. After standing for 15 min, add 200 μL of 25 mM HAuCl 4 solution and stirred for 50 min.

[0037] (3) Add 360 μL of 1M HCl solution to the above solution, and stir for 5 minutes.

[0038] (4) Quickly add 37.5 μL of 85.7 mM ascorbic acid solution and 7.5 μL of freshly prepared 10 mM NaBH to the above solution 4 The solution was stirred for 10 seconds and then allowed to stand for 5 hours, and purified by centrifugation to obtain the product.

[0039] The experimental results show that the size of the obtained gold nanorods is 11.9±2.0nm×57.6±6.3nm, the maximum absorption peak position is 889nm, the half-maximum width is 144nm, the shape is uniform, and the rod-shaped products are >99%.

Embodiment 3

[0041] (1) Weigh 140mg of cetyltrimethylammonium bromide and 25mg of sodium oleate, add 9.8mL of water, place in a 50°C water bath to dissolve completely, and then cool down to 30°C.

[0042] (2) Add 360μL of 4mM AgNO to the above solution 3 solution. After standing for 15 min, add 200 μL of 25 mM HAuCl 4 solution and stirred for 50 min.

[0043] (3) Add 864 μL of 1M HCl solution to the above solution, and stir for 5 minutes.

[0044] (4) Quickly add 37.5 μL of 85.7 mM ascorbic acid solution and 7.5 μL of freshly prepared 10 mM NaBH to the above solution 4 The solution was stirred for 10 seconds and then allowed to stand for 5 hours, and purified by centrifugation to obtain the product.

[0045]The experimental results show that the size of the obtained gold nanorods is 12.2±2.0nm×77.0±6.9nm, the position of the maximum absorption peak is 1025nm, the half-maximum width is 168nm, the shape is uniform, and the rod-shaped products are >95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com