Homogenization Manufacturing Method of Inconel718 Alloy Disc Forging

A manufacturing method and technology of alloy discs, which are applied in the field of forging, can solve problems such as inability to purchase directly, and achieve the effect of improving plasticity and good organizational properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

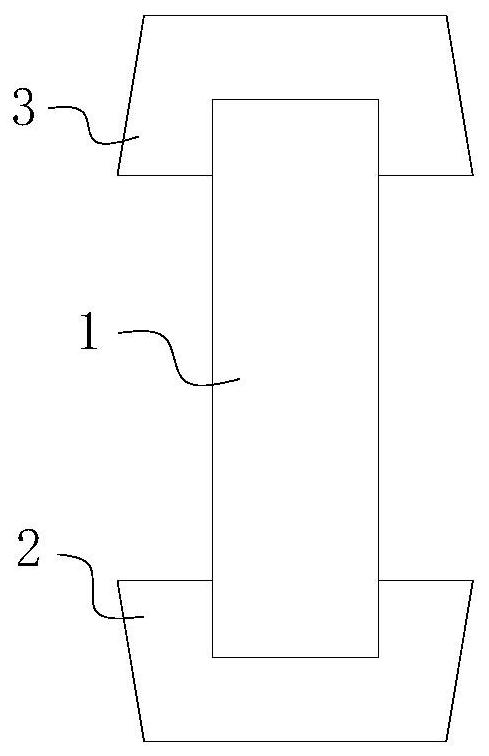

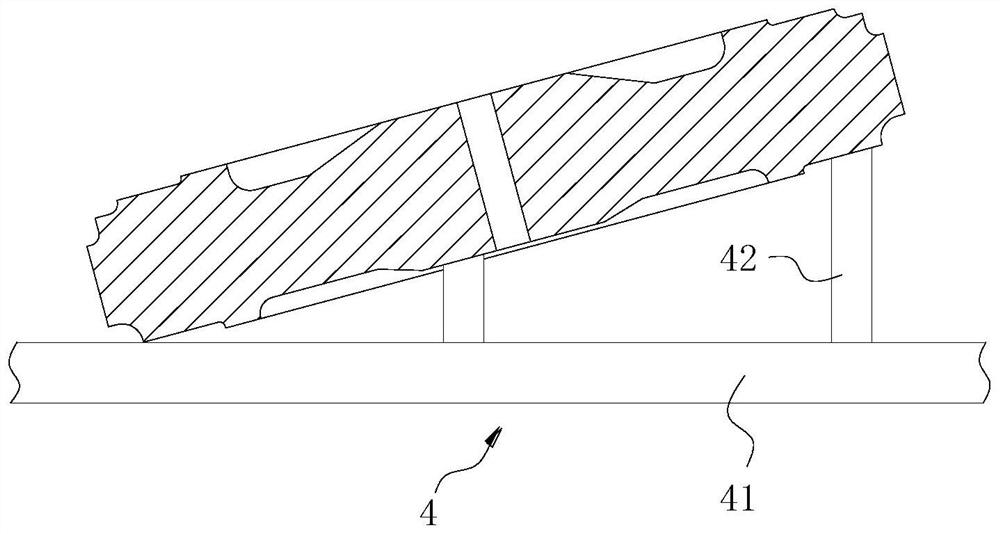

[0053] 1. The initial forging temperature of blank 1 is 1000°C, and the final forging temperature is 920°C; the amount of upsetting and elongating deformation is 30% to 50%;

[0054] 2. Heat treatment: First, heat the formed forging to 960°C, keep it in the furnace for 1-2 hours, then air-cool the forging to room temperature after it comes out of the furnace, then heat the forging to 710°C, keep it in the furnace for 7-9 hours, then heat the forging with The cooling rate of 50°C / h is cooled to 610°C with the furnace, and the forgings are air-cooled after being kept in the furnace for 7-9 hours.

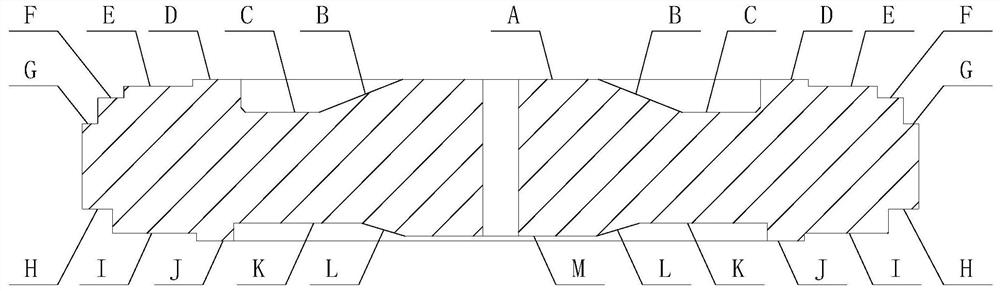

[0055] Machining the outer surface of the forging into image 3 The structure shown in the figure, A~M in the figure refers to the detection surface of different positions of the forging, for image 3 Surfaces A to M in the table were subjected to contact ultrasonic testing, and the testing results were as follows:

[0056] Detection surface B~L; clutter level: φ0.5-16dB; reached th...

Embodiment 2

[0061] 1. The initial forging temperature of blank 1 is 1050°C, and the final forging temperature is 930°C; the amount of upsetting and elongating deformation is 30% to 50%;

[0062] 2. Heat treatment: First, heat the formed forging to 970°C, keep it in the furnace for 1 to 2 hours, then air cool the forging to room temperature after it comes out of the furnace, then heat the forging to 720°C, keep it in the furnace for 7 to 9 hours, then heat the forging with The cooling rate of 55°C / h is cooled to 620°C with the furnace, and the forgings are air-cooled after being kept in the furnace for 7-9 hours.

[0063] Machining the outer surface of the forging into image 3 The structure shown in the figure, A~M in the figure refers to the detection surface of different positions of the forging, for image 3 Surfaces A to M in the table were subjected to contact ultrasonic testing, and the testing results were as follows:

[0064] Detection surface B~L; clutter level: φ0.5-16dB; reac...

Embodiment 3

[0069] 1. The initial forging temperature of blank 1 is 1100°C, and the final forging temperature is 920°C; the amount of upsetting and elongating deformation is 30% to 50%;

[0070] 2. Heat treatment: First, heat the formed forging to 980°C, keep it in the furnace for 1 to 2 hours, then air cool the forging to room temperature after it comes out of the furnace, then heat the forging to 730°C, keep it in the furnace for 7 to 9 hours, then heat the forging with The cooling rate of 60°C / h is cooled to 630°C with the furnace, and the forgings are air-cooled after being kept in the furnace for 7-9 hours.

[0071] Machining the outer surface of the forging into image 3 The structure shown in the figure, A~M in the figure refers to the detection surface of different positions of the forging, for image 3 Surfaces A to M in the table were subjected to contact ultrasonic testing, and the testing results were as follows:

[0072] Detection surface B~L; clutter level: φ0.5-16dB; reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com