Feed device and method of using same

A feeding device and feeding technology, applied in the direction of cleaning device for processing textile materials, equipment configuration for processing textile materials, processing of textile materials, etc., can solve problems such as environmental pollution, uneven feeding, easy to block pipes, etc., and achieve operational Convenient and fast, precise control of dosage, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

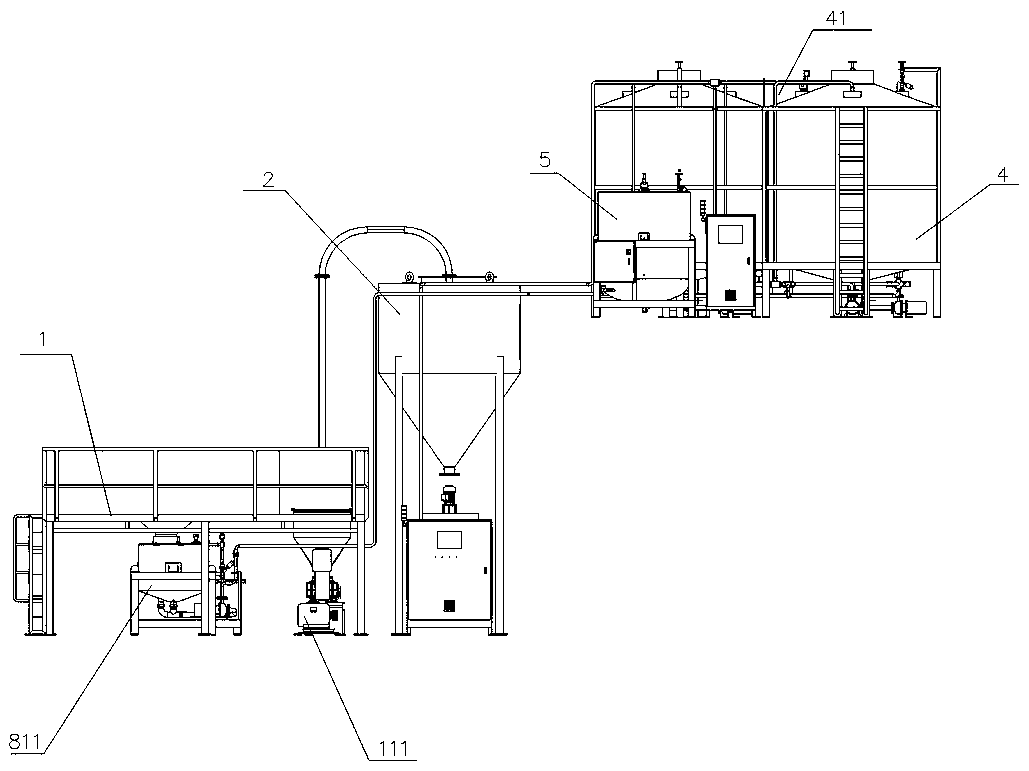

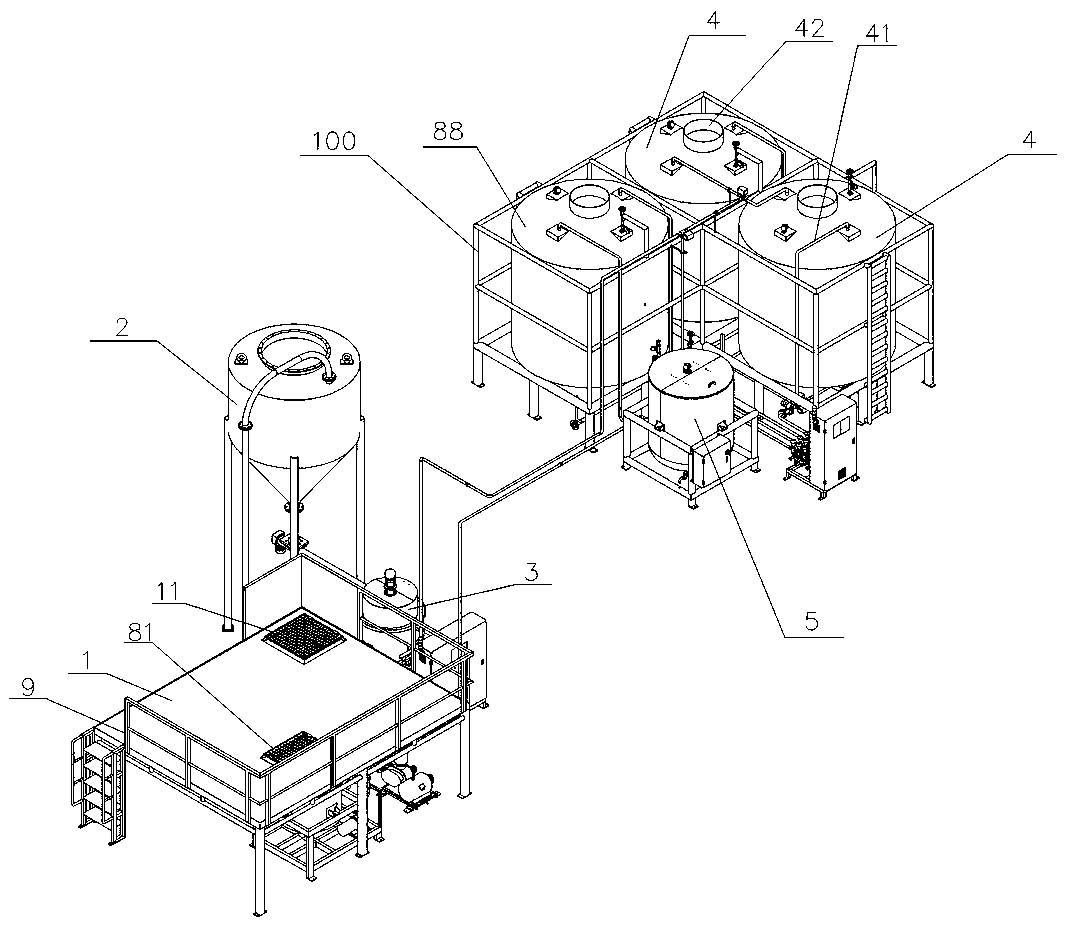

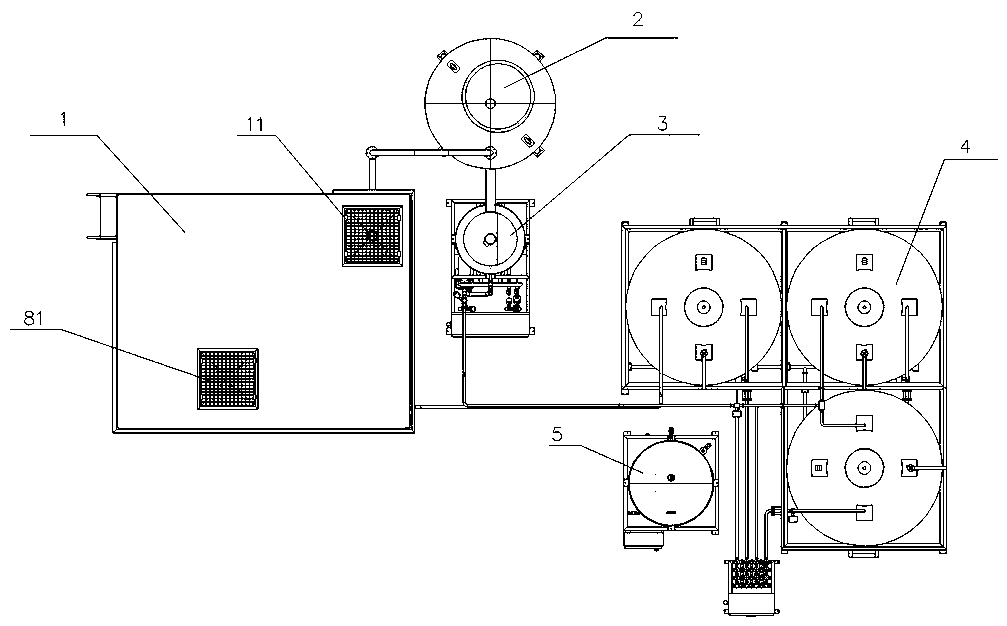

[0036] A variety of feeding devices, including interconnected feeding device and circulation storage device, said feeding device includes a material dump platform 1, a particle storage tank 2 and a yuanming powder liquid adjustment tank 3, said material dump platform 1 is provided with Yuanming powder discharge port 11 and soda ash discharge port 81, below the described material discharge platform 1 is provided with collector 111 and soda ash liquid adjustment tank 811, and described Yuanming powder discharge port 11 and collector 111 The soda ash pouring port 81 is connected with the soda ash liquid adjustment tank 811.

[0037] According to the feeding order of sodium sulfate, the discharge port 11 for sodium sulfate, the collector 111, the particle storage tank 2, the sodium carbonate liquid tank 3, the sodium sulfate liquid storage tank 4, the conveying and cleaning pipe 6, and the dyeing tank 7 are set in sequence. .

[0038] Described yuanming powder discharge port 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com