A firebrick measuring system based on machine vision

A machine vision, refractory brick technology, used in measuring devices, instruments, optical testing flaws/defects, etc., can solve problems such as affecting steel production, prone to misjudgment, and inability to build

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

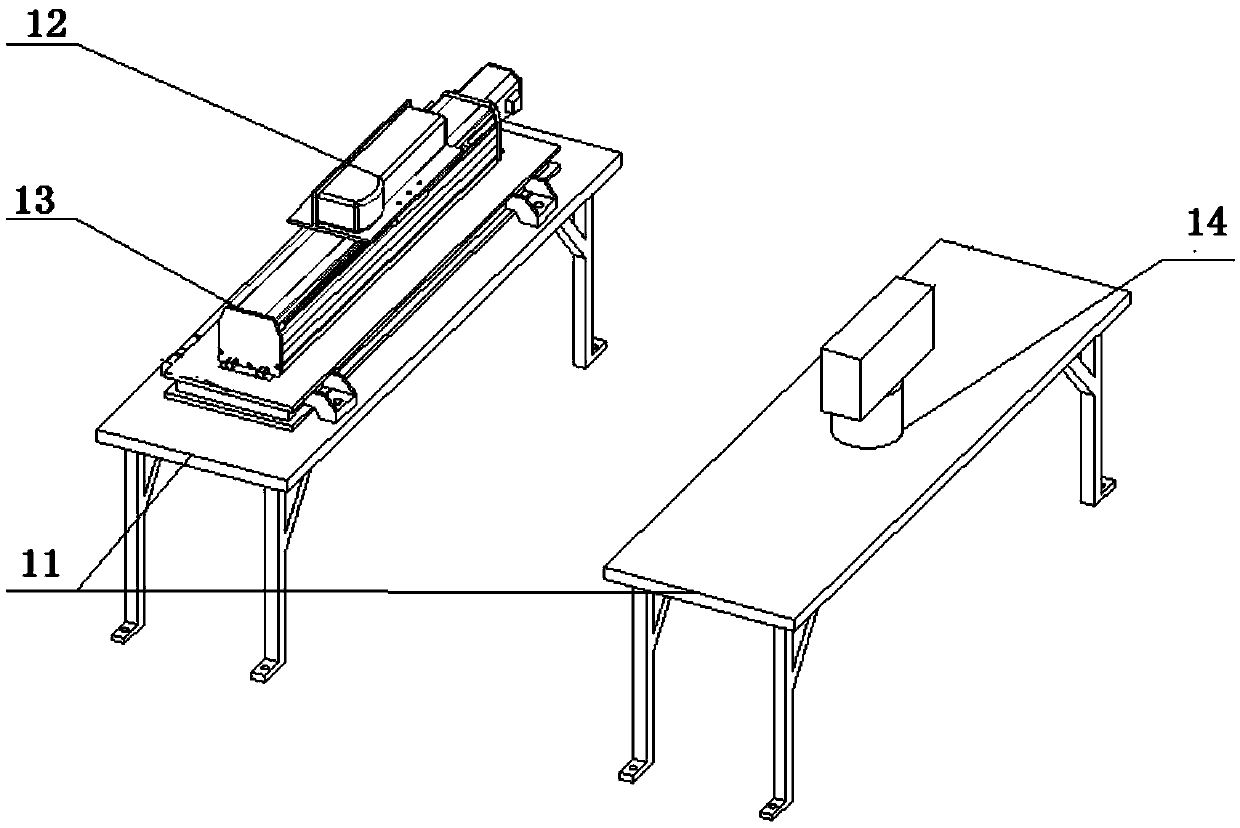

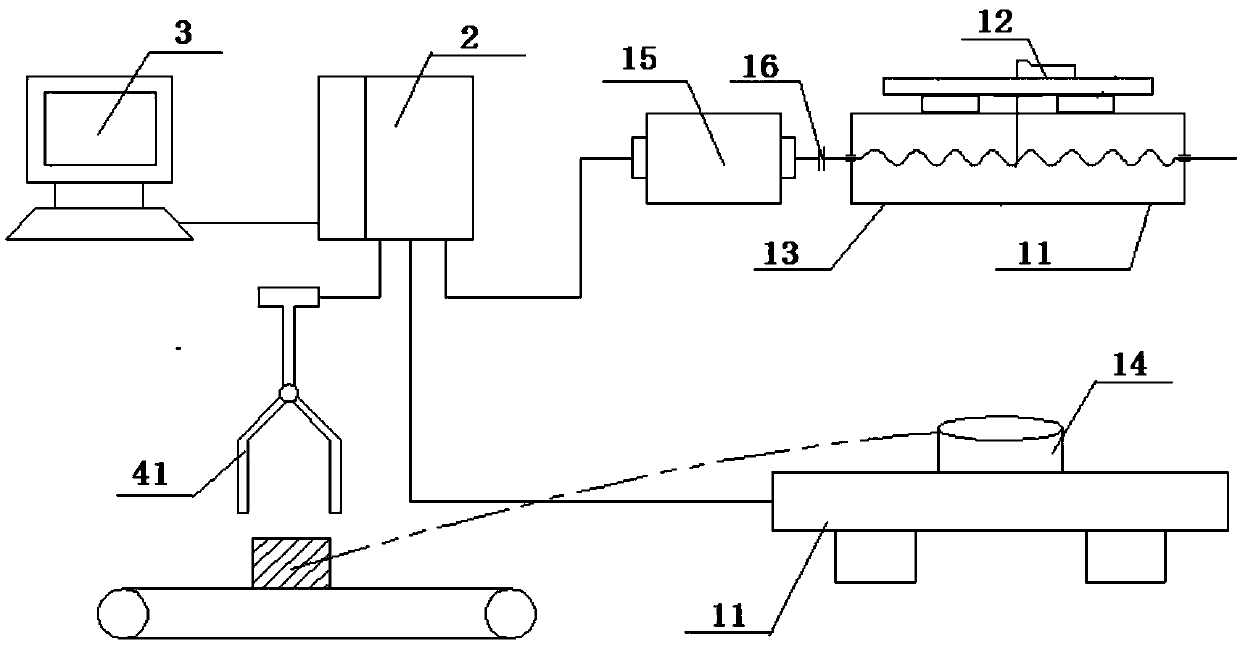

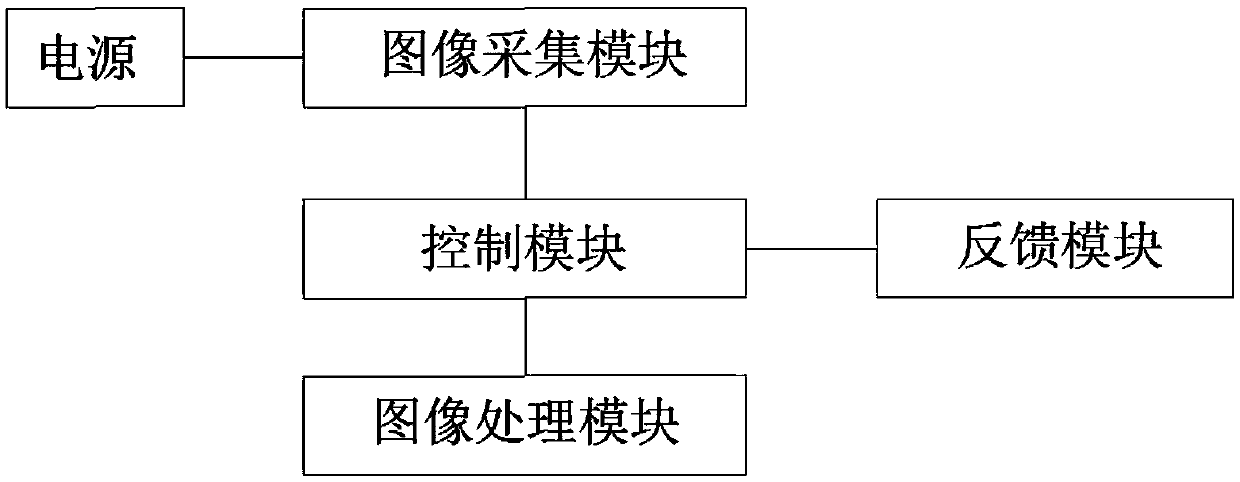

[0078] Such as Figure 1-3 As shown, the refractory brick measuring device based on machine vision includes an image acquisition module 1, a control module 2, an image processing module 3 and a feedback module 4. The image acquisition module 1 has a base 11, and the base 11 is provided with a three-structure light laser sensor The guide rail 13 of 12, the stepper motor 15 drives the three-structured light laser sensor 12 to move through the coupling 16, the turntable 14 carrying the refractory brick is fixed on the base 11, and the three-structured light laser sensor 12 is aligned with the surface of the refractory brick to be tested and scanned 4 end faces of the refractory brick to be tested; the input end of the control module 2 is connected to the image acquisition module 1, and the output end of the control module 2 is respectively connected to the image processing module 3 and the feedback module 4, the feedback module 4 includes a travel switch, and executes the removal ...

Embodiment 2

[0145] A method for measuring the geometric dimensions of refractory bricks, comprising the following steps:

[0146] Step 1: Filter and denoise the original refractory brick color image to obtain the denoised image;

[0147] Step 2: In the denoised image, segment the refractory brick area to obtain the refractory brick image;

[0148] Step 3: Carry out morphological processing on the refractory brick image, make the edge of the refractory brick image transition smoothly, and remove the isolated point noise at the edge of the refractory brick image, and obtain the corrected refractory brick image;

[0149] Step 4: Use the Canny operator to perform edge detection on the corrected refractory brick image;

[0150] Step 5: use the Hough transform method and the K-means method to extract the straight line of the refractory brick shape to form the outer contour of the refractory brick, including the following steps:

[0151] Step 5-1: Consider a point (x, y) on the xy plane and a ...

Embodiment 3

[0181] In this embodiment, the refractory brick surface inclination angle is measured on the basis of threshold segmentation of the refractory brick image, and the acquisition of the refractory brick image, filtering and noise reduction processing and segmentation of the refractory brick area are the same as in embodiment 2.

[0182] A method for identifying scratches on the surface of refractory bricks based on frequency domain filtering enhancement, including the following steps:

[0183] Step 1: Filter and denoise the original refractory brick color image collected by the sensor to obtain the denoised image; in the denoised image, segment the refractory brick area to obtain the grayscale image of the refractory brick, such as Figure 4 shown;

[0184] Step 2: convert the grayscale image of refractory bricks into a color image of refractory bricks, perform channel decomposition on the color image of refractory bricks, separate the images of R, G, and B channels, and obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com