PtCo/C electric catalyst and preparation method thereof

An electrocatalyst and catalyst technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of uniformity and smallness, affecting the uniformity of catalysts, and dispersion of carbon black particles, achieving small particle size, uniform distribution of catalyst particles, and preparation of low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

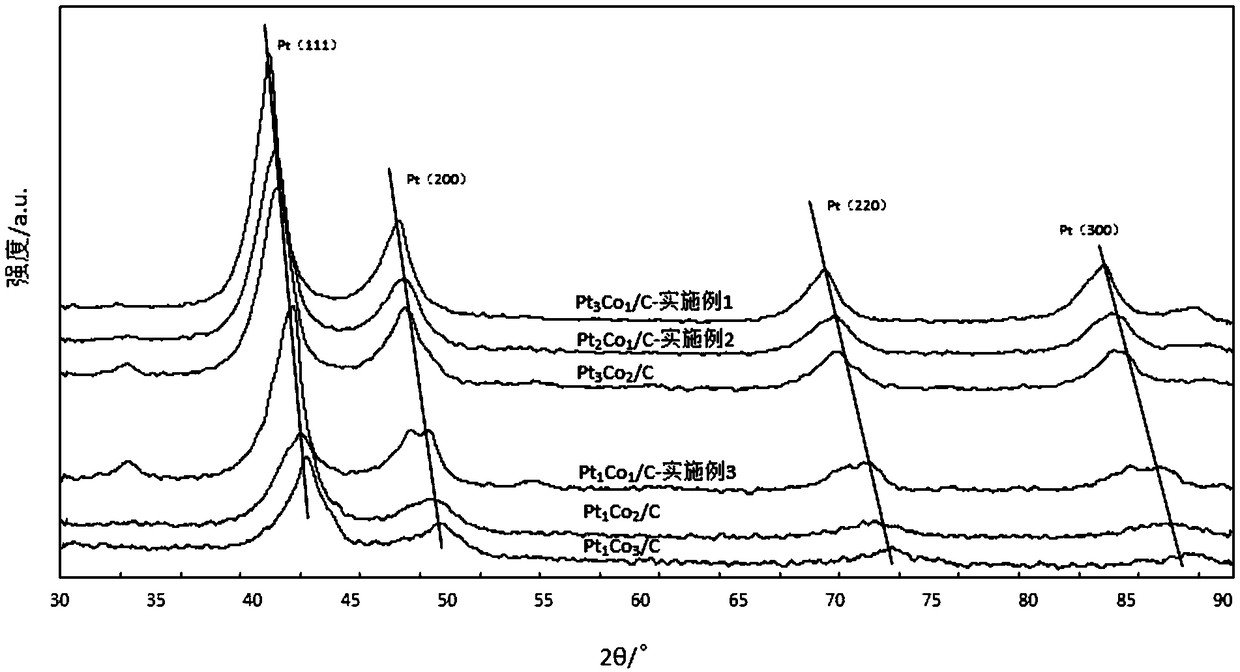

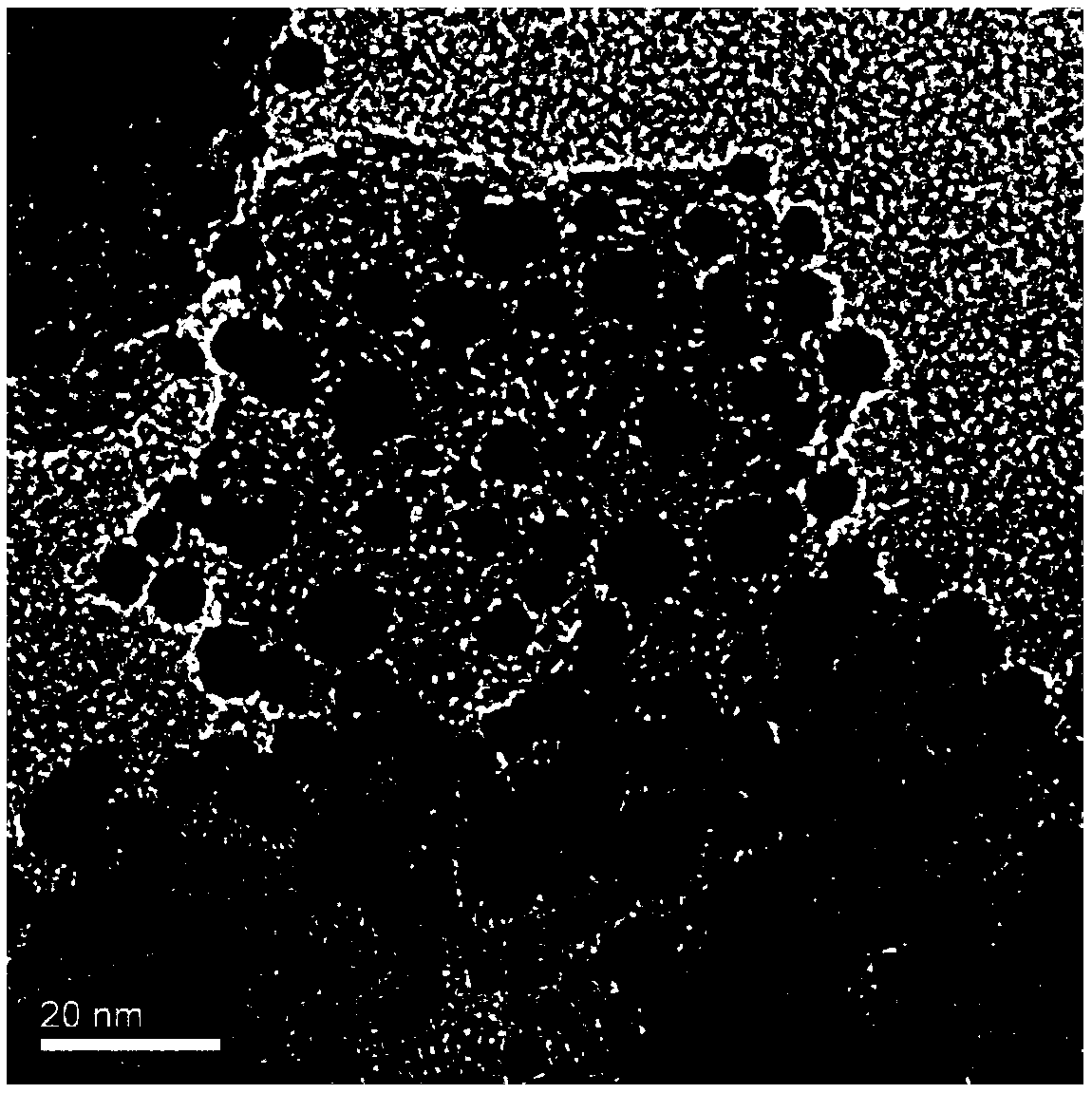

[0031] Pt 3 Co / C catalyst (Pt:Co molar ratio 3:1, mass accounts for 30% of the total mass of the catalyst), weigh the treated carbon powder slurry equivalent to 0.35g vulcan XC-72 carbon powder, add 0.7gNaCO 3 Adjust the pH, slowly drop 7ml of chloroplatinic acid solution, 1.5ml of cobalt chloride solution and prepared 1.5g of formaldehyde solution (preparation method: dilute with 14ml of deionized water per 1ml of formaldehyde solution) into the slurry in sequence under magnetic stirring, Stir evenly, and control the reaction temperature to react above 90°C. After filtration, cleaning and heat treatment, 30% Pt 3 Co / C catalyst, XRD test for catalyst, such as figure 1 as shown, figure 2 It is the TEM image of the PtCo / C electrocatalyst. It can be seen that the particle size of the catalyst Pt is uniform, well dispersed, and there is basically no solidification phenomenon. The average particle size of the particles is 5nm. The calculation shows that the cobalt element acco...

Embodiment 2

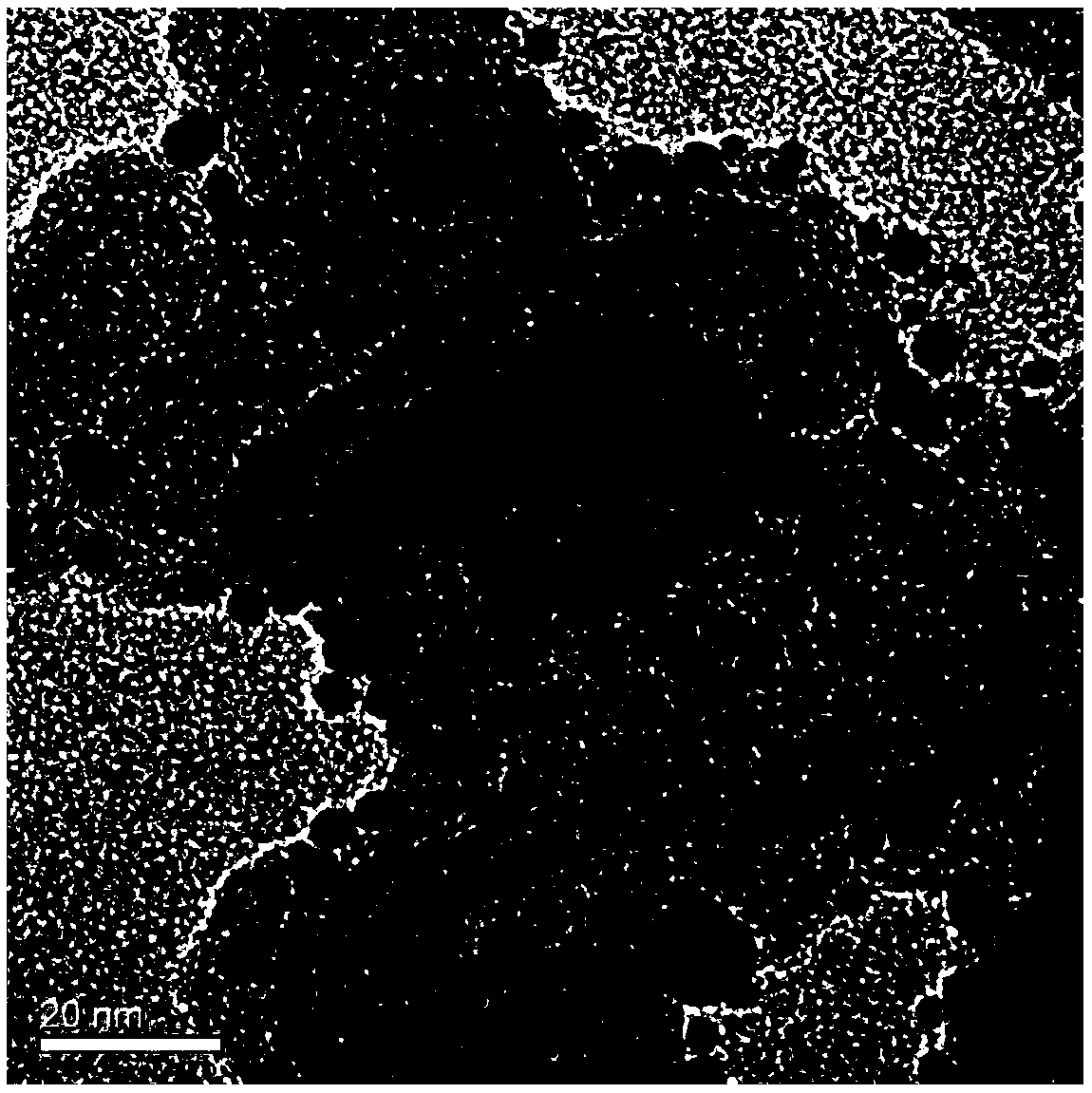

[0033] Change Pt and Co mol ratio among the embodiment 1, prepare Pt 2 Co / C catalyst (Pt:Co molar ratio 2:1, mass accounts for 30% of the total catalyst mass), weigh the treated carbon powder slurry equivalent to 0.35g Ketjen black carbon powder, add 0.7g NaHCO in sequence according to the above steps 3 Adjust the pH, slowly drop 6ml of platinum acetylacetonate solution, 1.5ml of cobalt acetylacetonate solution and prepared 0.5g of ethylene glycol solution into the slurry in turn under magnetic stirring, and stir evenly to control the reaction temperature above 90°C. After filtration, cleaning and heat treatment, 30% Pt 2 Co / C catalyst, get catalyst and carry out XRD test ( figure 1 ), image 3 It is the TEM image of the PtCo / C electrocatalyst. It can be seen that the Pt particles of the catalyst are uniform in size, well dispersed, and there is basically no solidification phenomenon. 32.01%, the theoretical ratio is 33.3%.

Embodiment 3

[0035] Change the Pt and Co molar ratio in Example 1 to prepare a PtCo / C catalyst (Pt: Co molar ratio 1:1, the mass accounts for 30% of the total mass of the catalyst), and weigh the treated carbon equivalent to 0.35g of carbon nanotubes Powder slurry, add 0.8g NaHCO successively according to the above steps 3 Adjust the pH, slowly drop 5.5ml of chloroplatinic acid solution, 3ml of cobalt nitrate solution and the prepared 1.5g of ethylene glycol solution into the slurry under magnetic stirring, and stir evenly to control the reaction temperature above 90°C. After filtration, washing and heat treatment, a 30% PtCo / C catalyst was obtained. Get catalyst and carry out XRD test ( figure 1 ), Figure 4 It is the TEM image of the PtCo / C electrocatalyst. It can be seen that the Pt particles of the catalyst are uniform in size, well dispersed, and there is basically no solidification phenomenon. 49.4%, the theoretical proportion is 50%.

[0036] Table 1 shows the mass specific acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com