Lithium ion solid conductor, preparation method thereof and all-solid lithium battery

A lithium-ion, solid-state technology, used in secondary batteries, circuits, electrical components, etc., can solve problems such as poor stability of metal lithium, dead lithium", and limited development and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of a lithium ion solid conductor, comprising the following steps:

[0042] A) will Li 2 S, P 2 S 5 , LiCl and LiBr are weighed according to the stoichiometric ratio in formula 1, and then high-energy ball milling is carried out to obtain the initial powder;

[0043] Li 6 P.S. 5 Cl z m 1-z Formula 1;

[0044] In formula 1, M is Br or I; 0.1≤z<1;

[0045] B) Sintering the primary powder material to obtain a lithium ion solid conductor.

[0046] In the present invention, with reference to the stoichiometric ratio in formula 1, Li with a purity of 99% or more 2 S, P 2 S 5 , LiCl and LiM (M=Br, I) are weighed according to the molar ratio x:y:z:(1-z), wherein, 2x+z+(1-z)=6; x+5y=5; Z=0 ~1. After weighing, the above-mentioned raw materials are subjected to high-energy ball milling under the condition that the water content is less than 10 ppm to obtain powdery raw materials.

[0047] The rotational speed o...

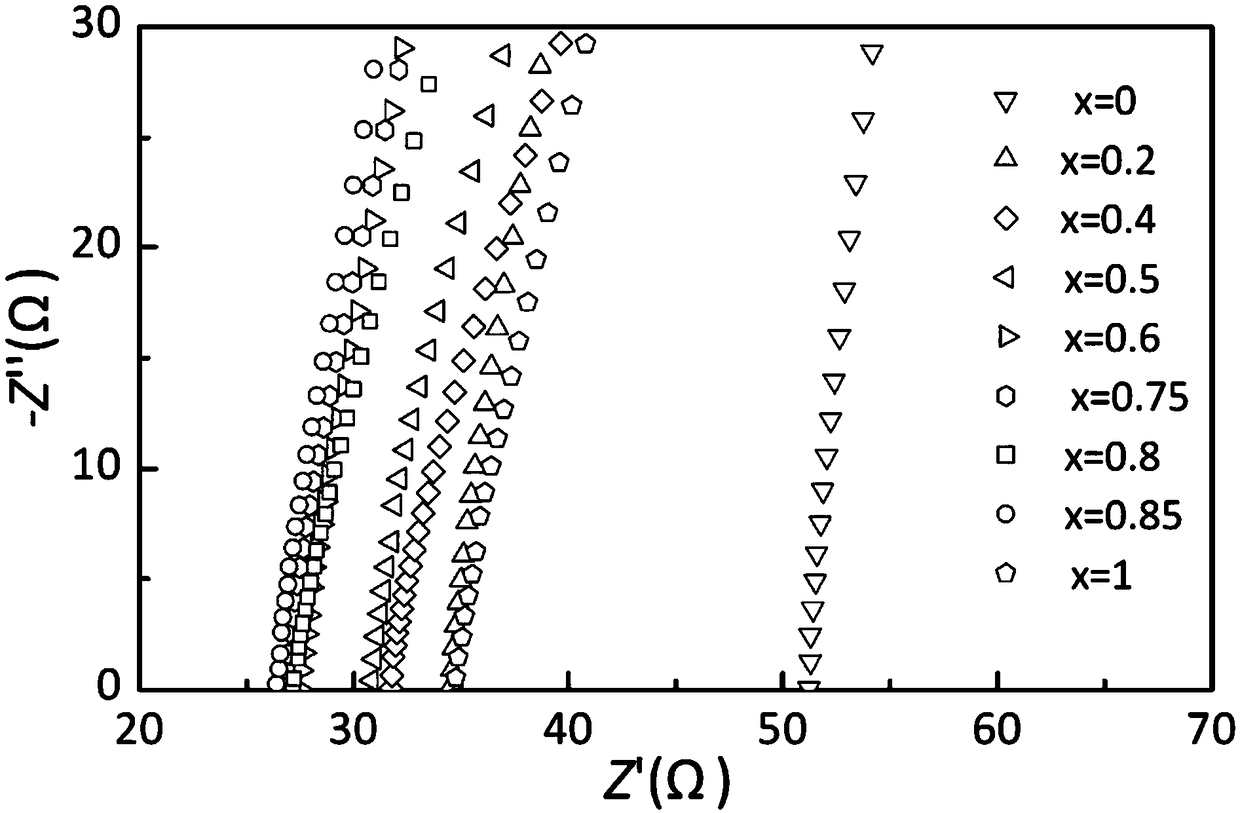

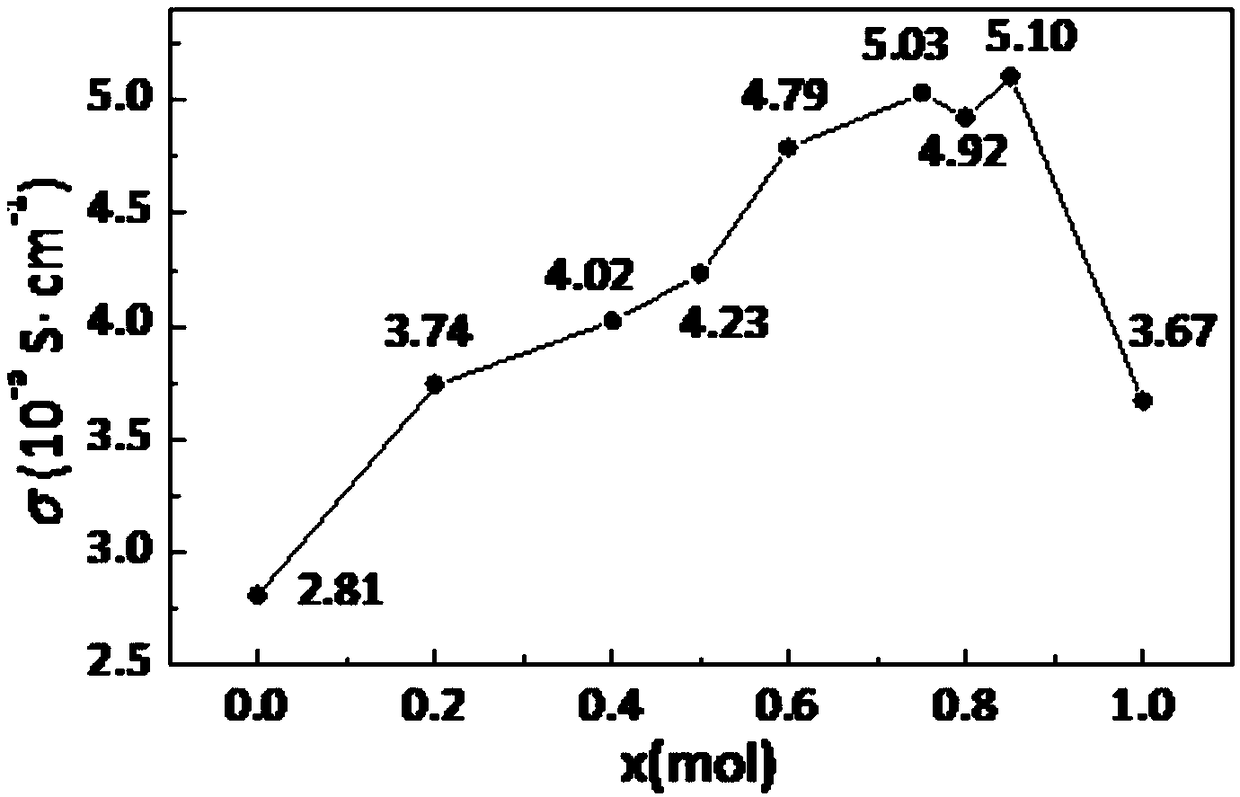

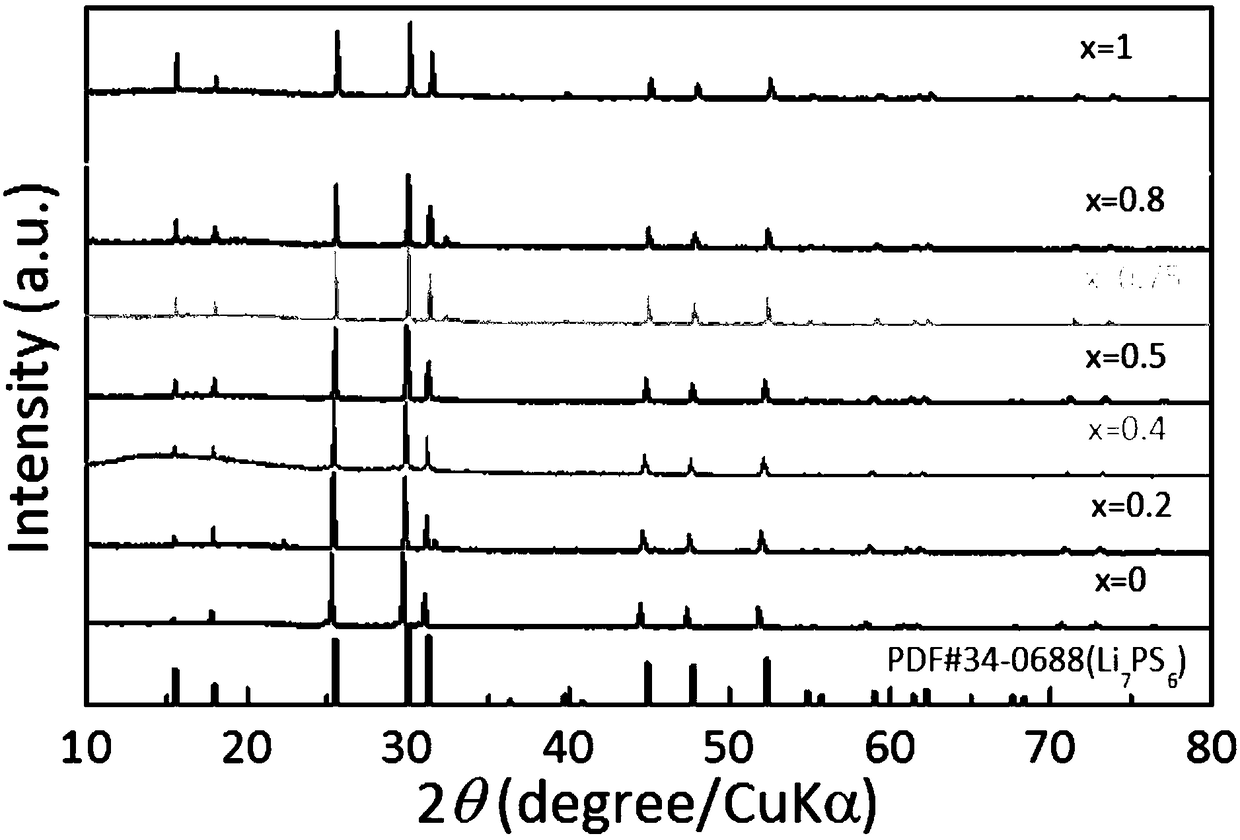

Embodiment 1~8

[0058] Under the protection of argon atmosphere, Li with a purity of more than 99% 2 S, P 2 S 5 , LiCl, and LiBr are weighed according to the molar ratio x:y:z:(1-z), wherein, 2x+z+(1-z)=6; x+5y=5; Z=0.2, 0.4, 0.5, 0.6 , 0.75, 0.8, 0.85, 1. Under the condition that the water content is less than 10ppm, at 350rpm; the time of high-energy ball milling is 15h; the ball-to-material ratio of high-energy ball milling is preferably 45:1. Finally, the primary powder material is obtained, and the primary powder material is taken out, grinded evenly, and then pressure-pressed to obtain a sheet-shaped primary material, and the sheet-shaped primary material is loaded into a sintering mold. Heat the sintering mold with the above flake raw material to the set temperature of 550°C at a heating rate of 2°C / min, keep it warm for 4h, cool down to room temperature with the furnace, take out the flake sintered product and grind it under the condition that the water content is less than 100ppm ...

Embodiment 9~16

[0063] Under the protection of argon atmosphere, Li with a purity of more than 99% 2 S, P 2 S 5 , LiCl, and LiI are weighed according to the molar ratio x:y:z:(1-z), wherein, 2x+z+(1-z)=6; x+5y=5; Z=0.2, 0.4, 0.5, 0.6 , 0.75, 0.8, 0.85, 1. Under the condition that the water content is less than 10ppm, at 350rpm; the time of high-energy ball milling is 15h; the ball-to-material ratio of high-energy ball milling is preferably 45:1. Finally, the primary powder material is obtained, and the primary powder material is taken out, grinded evenly, and then pressure-pressed to obtain a sheet-shaped primary material, and the sheet-shaped primary material is loaded into a sintering mold. Heat the sintering mold with the above flake raw material to the set temperature of 550°C at a heating rate of 2°C / min, keep it warm for 4h, cool down to room temperature with the furnace, take out the flake sintered product and grind it under the condition that the water content is less than 100ppm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com