Functional powder grease and preparation and application thereof

A functional powder and functional technology, which can be used in applications, additional food elements, animal feed, etc., can solve the problem of antioxidants not being able to isolate oil from oxidation and contact with metal ions, liquid oil storage, transportation, inconvenient use, and lack of oil Functional enhancement or synergistic effects, etc., to achieve the effects of improving embryo survival and litter size, promoting lochia discharge in the body, and improving oxidative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

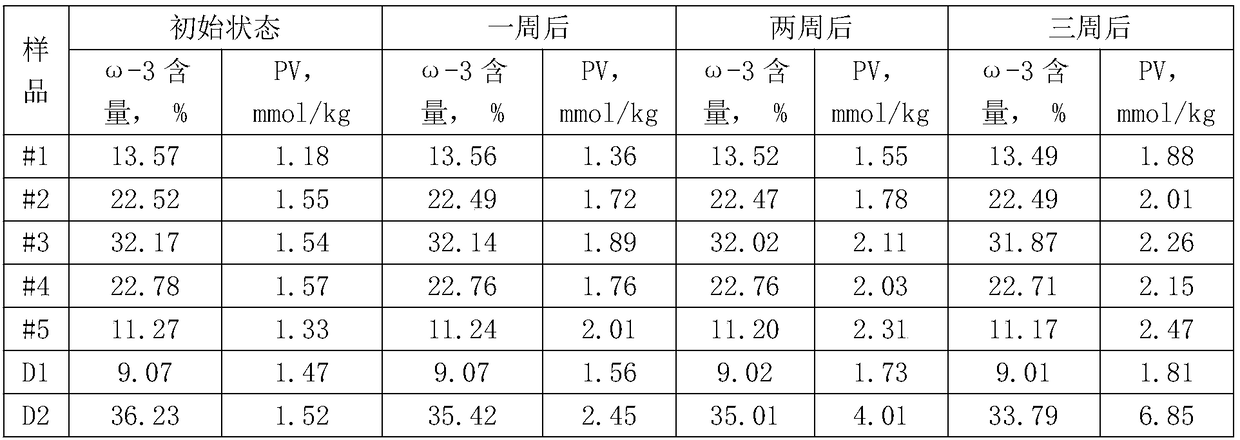

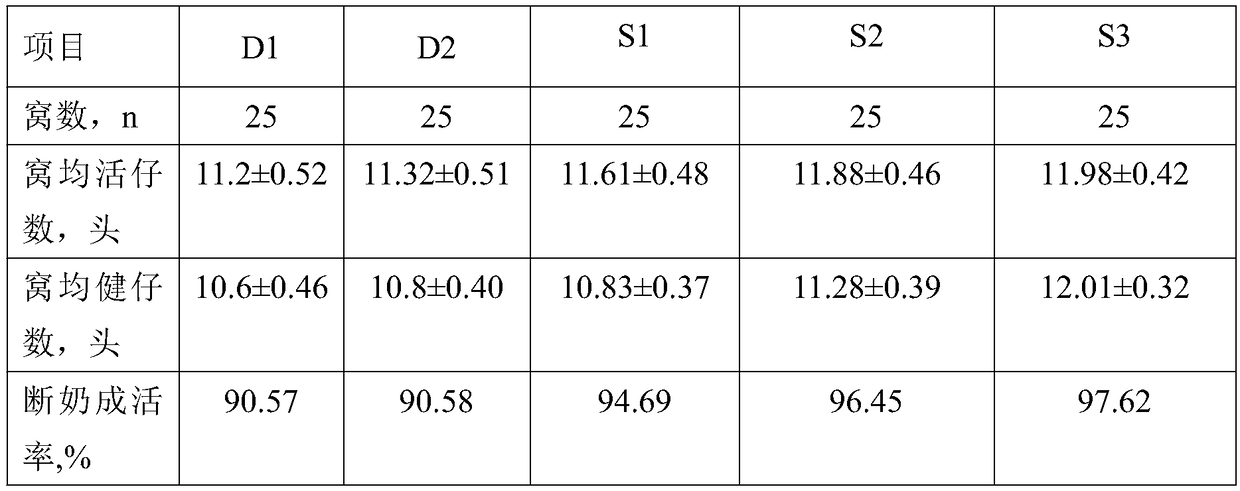

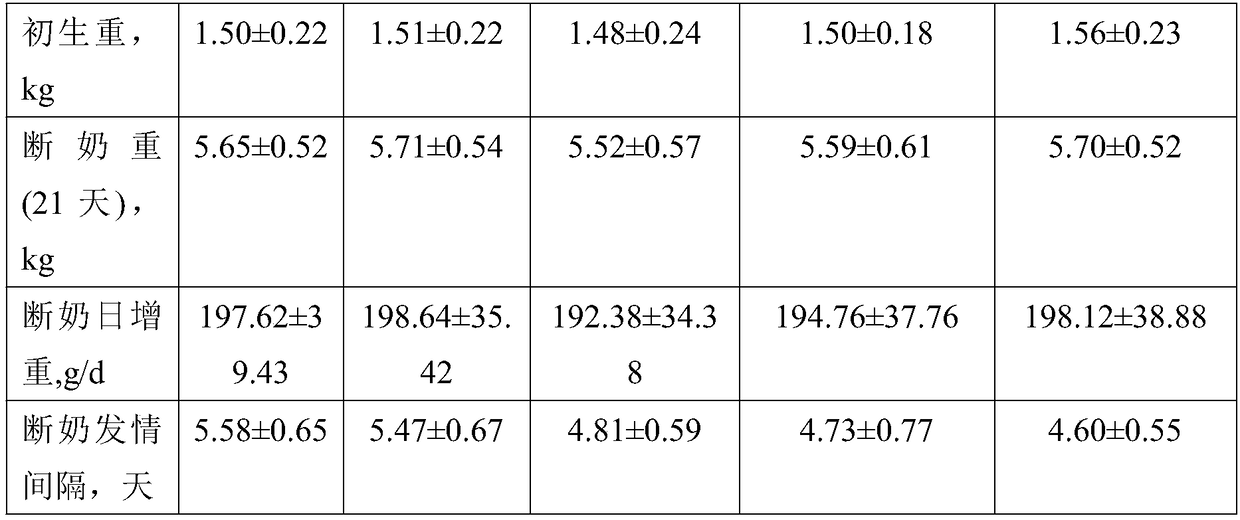

Examples

preparation example Construction

[0026] The preparation method for preparing the above-mentioned functional powder oil comprises the following steps:

[0027] (1) Dissolve the wall material in water according to the above composition ratio, heat to 40-80°C, stir evenly to make it fully dissolved, then add stabilizer, stir evenly;

[0028] The purpose of step (1) is to prepare a wall material solution prepared by brown sugar and maltodextrin, and fully dissolve the stabilizer, which is generally prepared by heating and stirring in a closed environment.

[0029] (2) According to the above composition ratio, heat the core material to 60-90°C, add an emulsifier, stir evenly, and make it fully dissolve;

[0030] The purpose of step (2) is to heat the core material, and stir and fully dissolve the emulsifier.

[0031] (3) Mix the two solutions described in step (1) and step (2), heat preservation and stirring at 60-80°C or high-speed shearing for 15-30 minutes, fully emulsify, and then homogenize under high pressu...

Embodiment example 1

[0036] The preparation of functional powder oil comprises the following steps:

[0037] (1) Weigh 41.3 parts by weight of brown sugar and 28 parts by weight of maltodextrin with a DE value of 8-10, add 0.3 parts of sodium citrate, add it to 70 parts by weight of water, and stir it evenly at 40°C to make it completely dissolved;

[0038] (2) Weigh 30 parts by weight of linseed oil, heat it to 60° C., then add 0.4 parts by weight of mono- and diglycerides, and stir to fully dissolve it;

[0039] (3) Then step (1) is mixed with the solution prepared in step (2), sheared at a high speed for 15 minutes at 60° C., and then subjected to homogenization treatment by a 15Mpa high-pressure homogenizer;

[0040] (4) The material obtained in step (3) is spray-dried again, and the drying parameters are as follows: the inlet air temperature is 150°C, and the outlet air temperature is 70°C.

[0041] The obtained functional powder oil has a surface oil content of 2.02%.

Embodiment example 2

[0043] The preparation of functional powder oil comprises the following steps:

[0044] (1) Weigh 20 parts by weight of brown sugar and 30 parts by weight of maltodextrin with a DE value of 8-10, add 0.5 part of sodium citrate and 0.5 part of sodium tripolyphosphate, and add them to 100 parts by weight of water. Stir evenly at ℃ to dissolve completely;

[0045] (2) Weigh 47.7 parts by weight of linseed oil, heat it to 75°C, then add 2.3 parts by weight of mono- and diglycerides, and stir to fully dissolve it;

[0046] (3) Then step (1) is mixed with the solution prepared in step (2), sheared at a high speed for 23 minutes at 70°C, and then subjected to homogenization treatment by a 28Mpa high-pressure homogenizer;

[0047] (4) The material obtained in step (3) is spray-dried again, and the drying parameters are as follows: the inlet air temperature is 170°C, and the outlet air temperature is 80°C.

[0048] The obtained functional powder oil has a surface oil content of 2.81%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com