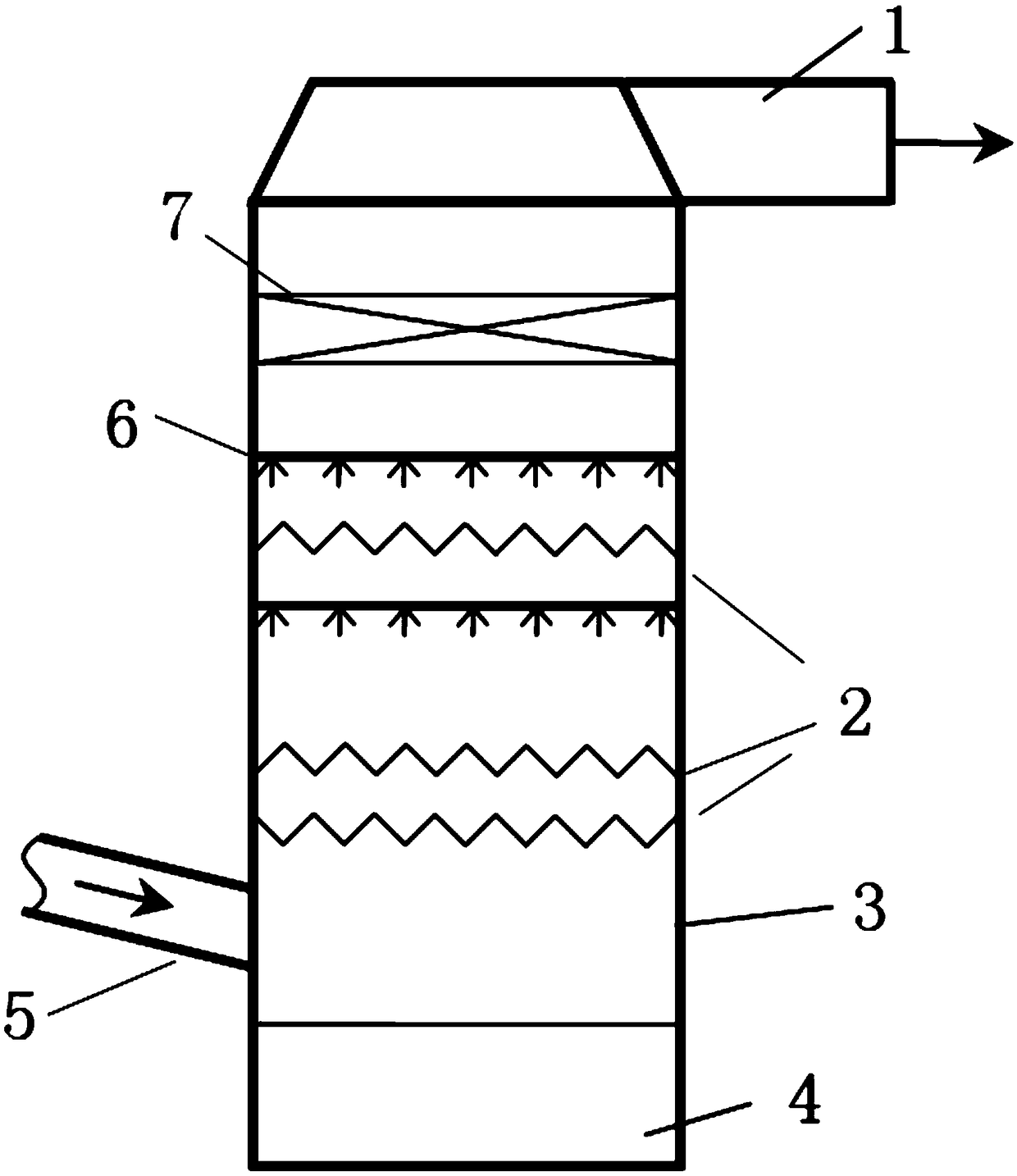

Wet desulfurization tower with ridge type trays

A wet desulfurization and desulfurization tower technology, applied in separation methods, chemical instruments and methods, use of liquid separation agents, etc., can solve the problems of low desulfurization efficiency of desulfurization towers, enhance desulfurization and dust washing effects, and increase gas-liquid contact area. , the effect of increasing the gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

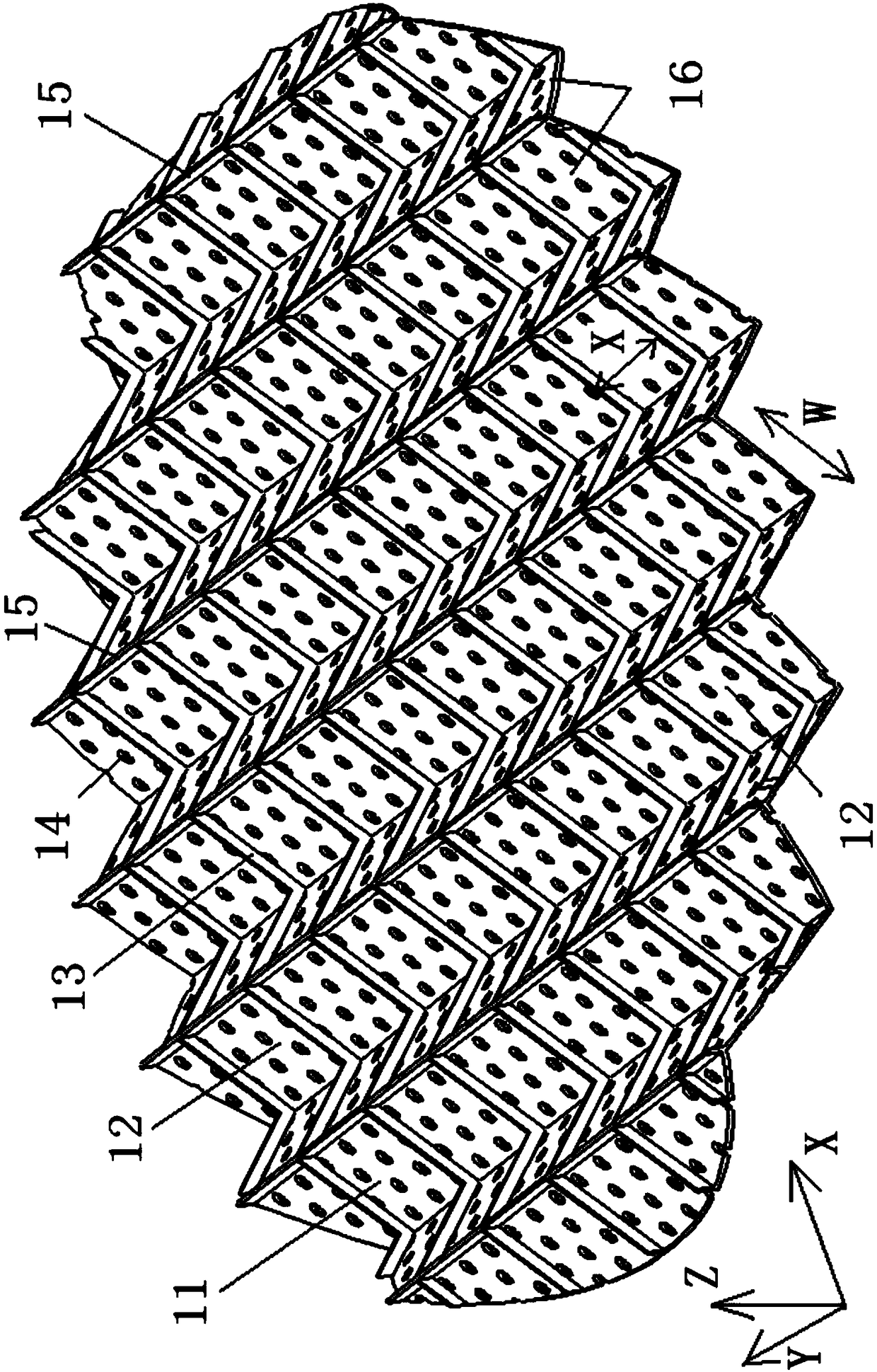

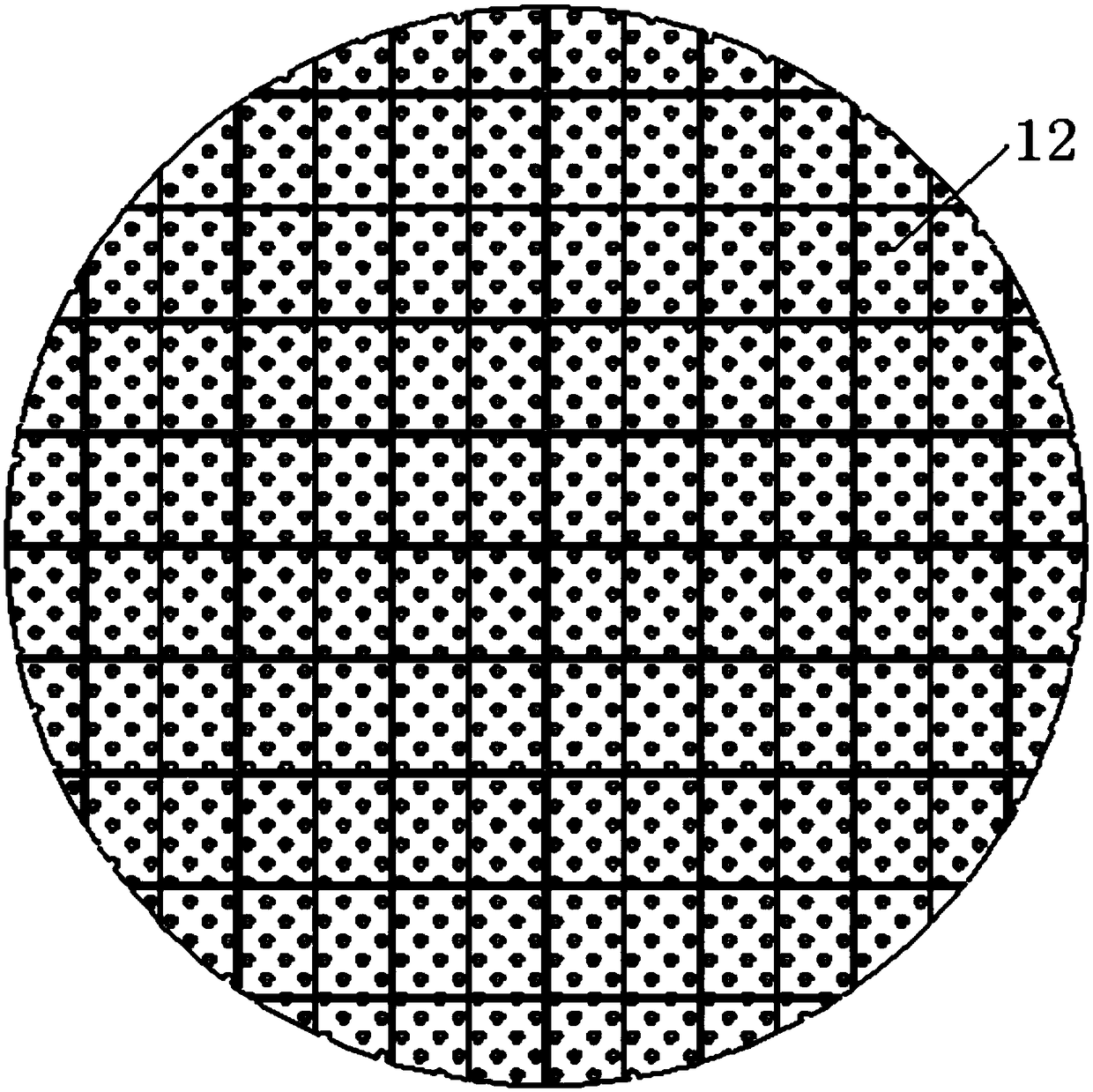

[0050] In the wet desulfurization tower of a 600,000-kilowatt unit, the inner diameter of the desulfurization tower body 3 is 16m, and there are 4 spray layers 6 in total, and the height difference between two adjacent spray layers 6 is 2m. A layer of ridge tray 2 is set at 2m below the bottom spraying layer 6. There are 16 longitudinal units 11 in the ridge tray 2. The width W of the orifice plate 12 and the spacing X between the orifice plates are 1.414m. The angle α with the horizontal plane (the plane where the XY axes are located) is 45°. The opening 14 of the orifice plate 12 is elliptical, the minor axis a is 70 mm, the major axis b is 99 mm, and the horizontal projection is a circle with a diameter of 70 mm. The openings 14 are arranged in staggered rows, the transverse spacing c of the openings 14 is 140 mm, and the longitudinal spacing (that is, the spacing between rows) d of the openings 14 is 140 mm. Correspondingly, the opening ratio of the orifice plate 12 is 28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com