Alloy catalyst for degrading formaldehyde, and preparation method and application of alloy catalyst

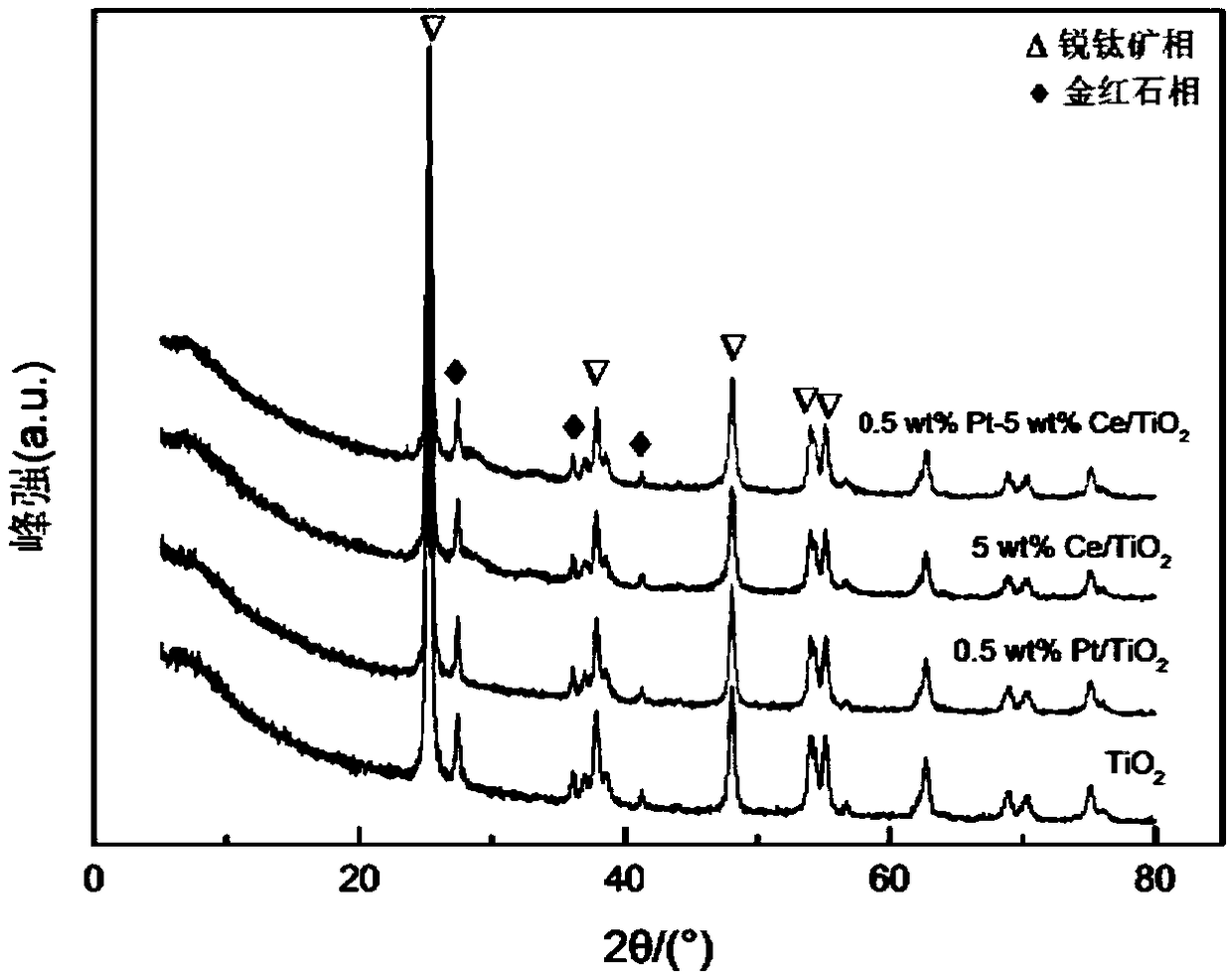

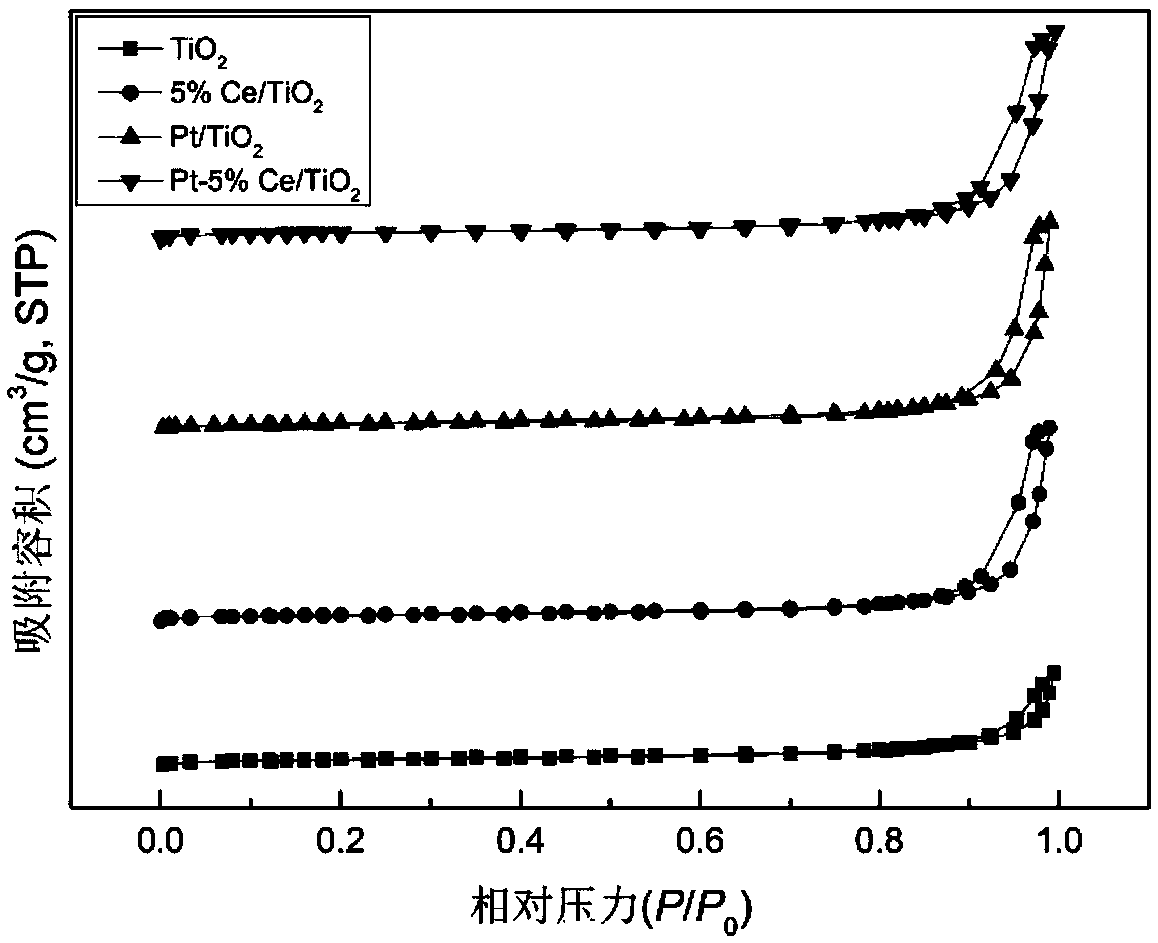

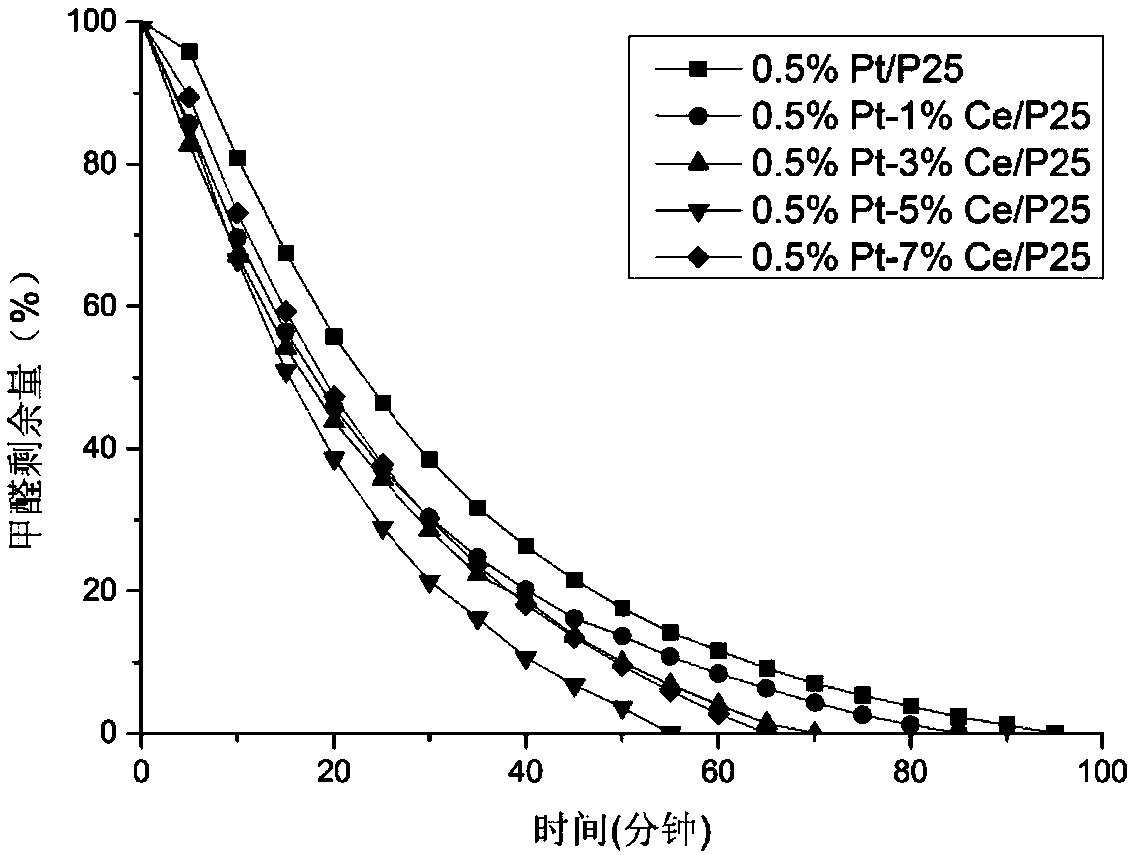

An alloy catalyst and formaldehyde technology, applied in the field of nanomaterials, can solve the problems of unsatisfactory catalytic oxidation effect, inability to produce cost-effectiveness, large platinum loading capacity, etc., and achieve the advantages of adsorption, enrichment of oxygen vacancies, and reduction of nanoparticle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An embodiment of the alloy catalyst for degrading formaldehyde of the present invention, the alloy catalyst described in this embodiment is prepared by the following method:

[0040] (1) Add 0.0558g of cerium nitrate hexahydrate crystals to 5.5ml of deionized water, stir at room temperature for 0.1 hour to completely dissolve in deionized water, and add 1.8g of TiO at 25°C 2 Nanomaterials, magnetically stirred for 4 hours, where Ce relative to TiO 2The mass fraction is 1%, and then put the uniformly mixed sample into an oven to dry at 110°C for 12 hours, cool the dried sample, grind it, and roast it at 400°C for 4 hours to obtain a Ce / P25 solid material;

[0041] (2) Add 1.5g Ce / P25 in 30ml of deionized water, stir magnetically for 0.5 hours to fully disperse in deionized water, add 3.984ml of chloroplatinic acid hexahydrate solution with a concentration of 3.958g / L at 25°C, and continue stirring 1 hour, wherein the percentage of Pt mass and Pt and Ce / P25 carrier mass ...

Embodiment 2

[0046] An embodiment of the alloy catalyst for degrading formaldehyde of the present invention, the alloy catalyst described in this embodiment is prepared by the following method:

[0047] (1) Add 0.167g of cerium nitrate hexahydrate crystals to 5.5ml of deionized water, stir at room temperature for 0.1 hour to completely dissolve in deionized water, and add 1.8g of TiO at 25°C 2 Nanomaterials, magnetically stirred for 4 hours, where Ce relative to TiO 2 The mass fraction is 3%, and then put the uniformly mixed sample into an oven to dry at 110°C for 12 hours, cool the dried sample, grind it, and roast it at 400°C for 4 hours to obtain a Ce / P25 solid material;

[0048] (2) Add 1.5g Ce / P25 in 30ml of deionized water, stir magnetically for 0.5 hours to fully disperse in deionized water, add 3.984ml of chloroplatinic acid hexahydrate solution with a concentration of 3.958g / L at 25°C, and continue stirring 1 hour, wherein the percentage of Pt mass and Pt and Ce / P25 carrier mass ...

Embodiment 3

[0053] An embodiment of the alloy catalyst for degrading formaldehyde of the present invention, the alloy catalyst described in this embodiment is prepared by the following method:

[0054] (1) Add 0.279g of cerium nitrate hexahydrate crystals to 5.5ml of deionized water, stir at room temperature for 0.1 hour to completely dissolve in deionized water, and add 1.8g of TiO 2 Nanomaterials, magnetically stirred for 4 hours, where Ce relative to TiO 2 The mass fraction is 5%, and then put the uniformly mixed sample into an oven to dry at 110°C for 12 hours, cool the dried sample, grind it, and roast it at 400°C for 4 hours to obtain a Ce / P25 solid material;

[0055] (2) Add 1.5g Ce / P25 in 30ml of deionized water, stir magnetically for 0.5 hours to make it fully dispersed in deionized water, add 3.984ml of chloroplatinic acid hexahydrate solution with a concentration of 3.958g / L at 25°C, and continue stirring for 1 Hour, wherein the percentage of Pt mass and Pt and Ce / P25 carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com