Synchronization conveying belt and preparing method thereof

A conveyor belt and combined technology, applied in the field of synchronous conveyor belt and its preparation, can solve the problems of easily damaged materials and the surface of the synchronous conveyor belt, reduce the service life of the synchronous conveyor belt, easily destroy the internal structure of the conveyor belt, etc., and achieve the guaranteed strength , prevent stretching deformation, increase the effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

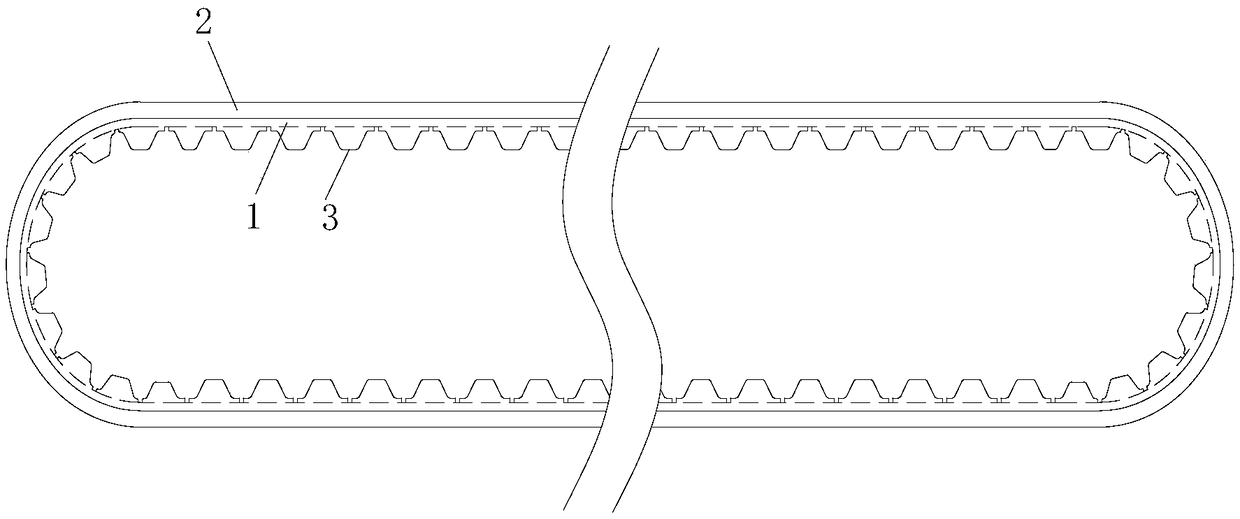

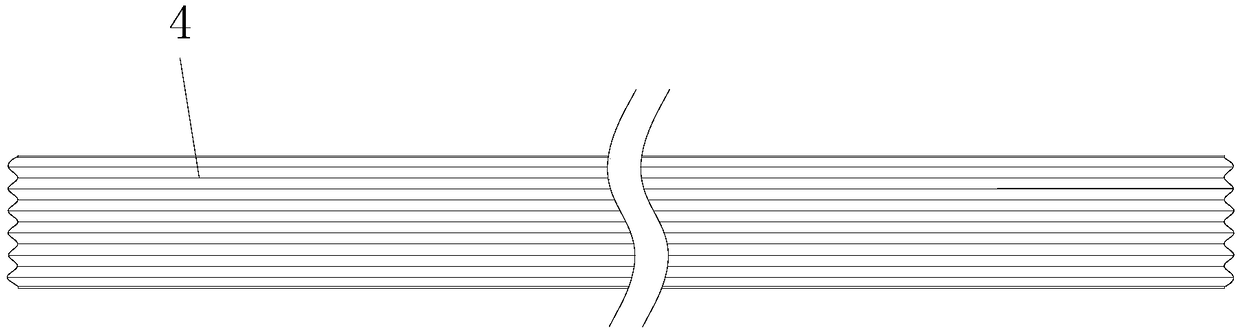

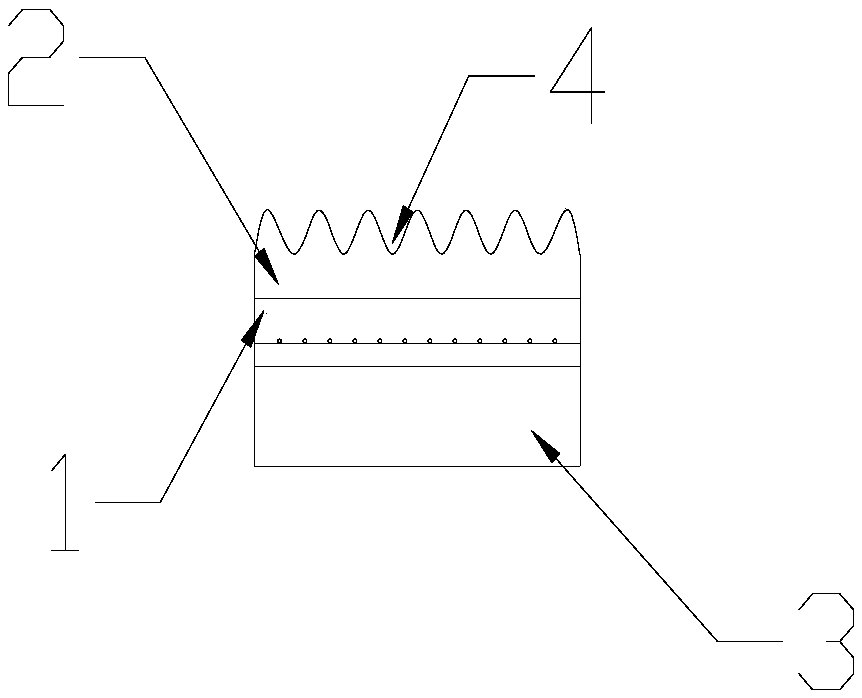

[0034] Such as Figure 1-Figure 3 As shown, a synchronous conveyor belt includes a synchronous conveyor belt body and a number of teeth arranged inside the synchronous conveyor belt body; it is characterized in that the synchronous conveyor belt body includes: a composite inner ring layer 1 and the outer ring layer 2, the belt teeth 3 are formed inside the inner ring layer 1, and several grooves 4 are arranged on the outer surface of the outer layer 2, and the direction of the grooves 4 is consistent with that of the synchronous conveyor belt The conveying direction is parallel.

[0035] Wherein, the inner ring layer 1 and the belt teeth 3 are integrally formed by die casting. The outer ring layer 2 is a molded transparent layer. The inner ring layer 1 and the outer ring layer 2 are compounded together to make a synchronous conveyor belt, so that the entire synchronous conveyor belt has no joints and ensures the strength of the synchronous conveyor belt. In addition, the tr...

Embodiment 2

[0040] A method for preparing a synchronous conveyor belt, comprising the following steps:

[0041] 1) The inner ring layer and belt teeth of the synchronous conveyor belt are molded;

[0042] 2) The outer ring layer of the synchronous conveyor belt is molded;

[0043] 3) Match the inner ring layer and the outer ring layer together and fix them under tension, heat, rotate and pressurize at the same time to make the inner ring layer and the outer ring layer compound together to make a synchronous conveyor belt rough billet;

[0044] 4) Grind the rough burr of the synchronous conveyor belt, and cut it with a slitting machine to obtain a synchronous conveyor belt of corresponding width.

[0045]Wherein, the inner ring layer is formed by vulcanization of PU, flow aid, anti-wear agent and pigmented steel wire, and the outer ring layer is formed by vulcanization of PU, flow aid, anti-wear agent, toughening agent and tackifier. Specifically, the preparation process of the inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com