Fish culture sewage treatment device

A sewage treatment device and fish farming technology, applied in water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem that the aquaculture sewage treatment device has no control ability and reduce the aquaculture sewage treatment The purification efficiency of the device, the damage of the aquaculture sewage treatment device, etc., achieve the effect of good sewage purification effect, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

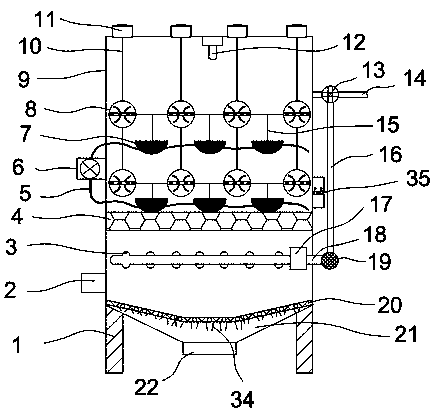

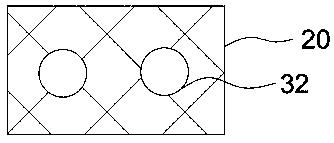

[0024] Such as Figure 1-2 As shown, the fish farming sewage treatment device includes a casing 9, the side of the casing 9 is provided with a sewage inlet 2, and a blower 6 is arranged directly above the sewage inlet 2 and is installed on the side wall of the casing 9, and the upper end of the other side wall of the casing 9 A water outlet pipe 14 is provided, and a control panel 34 is arranged below the water outlet pipe 14 and is installed on the outer wall of the box body 9. The upper end of the box body 9 is evenly distributed with a motor 11, and a filter screen 4 is arranged inside the box body 9, and the filter screen 4 is installed at the sewage inlet 2. Above, the lower end of the filter screen 4 is provided with a sedimentation area 21 , and the lower end of the sedimentation area 21 is provided with a slag outlet 22 . By setting the filter screen inside the box, the aquaculture sewage can be pre-filtered, the filtration capacity of the device can be improved, and t...

Embodiment 2

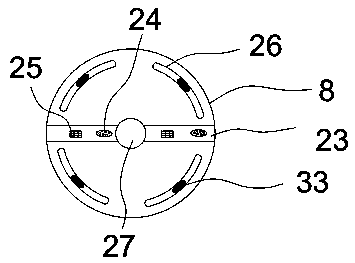

[0030] Such as Figure 4-5 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: the lower end of the motor 11 is connected to the steel wire 10, the lower end of the steel wire 10 is evenly distributed with silica gel balls 8, and the surface where the lateral center line of the silica gel ball 8 is located is provided with a chute 23, and the sliding The inside of the slot 23 is fixedly connected with several magnets 25 and activated carbon balls 24, the magnets 25 and the activated carbon balls 24 are alternately distributed, and a slider 27 is arranged on the outside of the chute 23, and one end of the slider 27 is connected to the magnetic disk 29 through a spring 28, and the magnetic disk 29 is on the slide. Inside the slot 23 and above the magnet 25, the magnetic disk 29 is the same as the opposite surface of the magnet 25. The other end of the slider 27 is connected with a net rope 15, and the net rope 15 is connected to the silicone ball...

Embodiment 3

[0035] Sewage treatment comparison test:

[0036] Test objects: the fish breeding sewage treatment device of the present invention (test group 1), traditional aquaculture sewage treatment equipment (test group 2);

[0037] Experimental conditions: The same type of water pump is used to draw the same aquaculture sewage, and the same amount of sewage is poured into the two sewage treatment devices at the same time for purification treatment. And the purification time is the same;

[0038] Test process:

[0039] At the same time, the same amount of aquaculture sewage was taken to the two sewage treatment devices for purification for 10 minutes, and the purified water was extracted for water quality analysis.

[0040] result:

[0041] Test group 1

[0042]

[0043] Test group 2

[0044]

[0045] It can be seen from the above two tables that the aquaculture sewage treatment device of this device has good sewage treatment effect, high dissolved oxygen after purification, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com