High temperature-resistant quartz fiber reinforced silica-based composite material, and preparation method and application thereof

A technology of quartz fiber and silica, applied in the field of composite materials, can solve the problems of decreased tensile strength, cracks on the fiber surface, poor tensile strength, etc., and achieve high temperature resistance, high temperature resistance and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

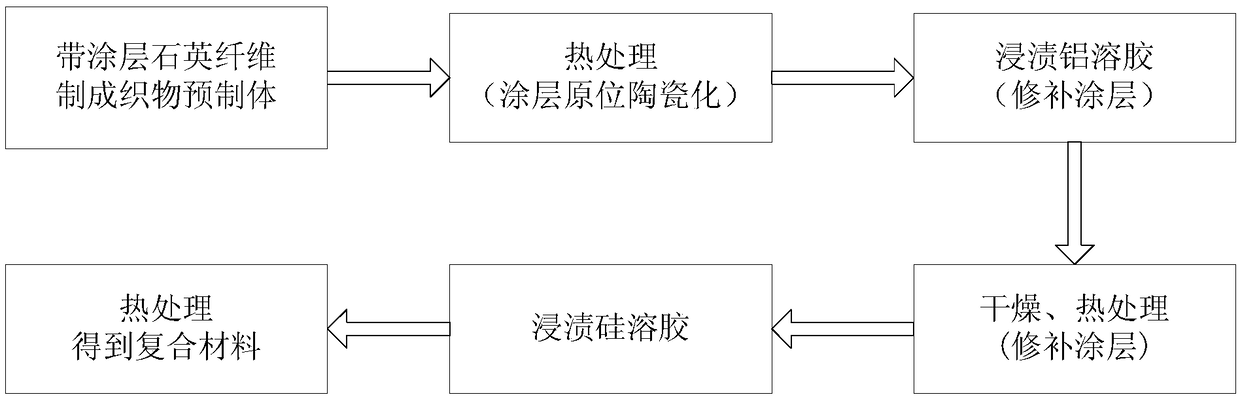

[0029] An embodiment of the present invention provides a method for preparing a high-temperature-resistant quartz fiber-reinforced silica-based composite material, comprising the following steps:

[0030] Step (1): Using quartz fiber with a coating on the surface of the monofilament to make a fabric preform, wherein the coating contains water and alumina and / or nano-alumina particles, and the fabricated fabric is prefabricated The body is heat-treated to obtain a fabric prefabricated body with a ceramic coating on the surface of the monofilament;

[0031] Specifically, in the embodiment of the present invention, the quartz fiber with a coating on the surface of the monofilament can be obtained by coating the surface of the quartz fiber monofilament with a coating containing water and alumina and / or nano-alumina particles, and the coating is preferably mainly Composition is Al 2 o 3 ·nH 2 O and epoxy resin; described quartz fiber monofilament is preferably the quartz fiber m...

Embodiment 1

[0047] see figure 1 , the present embodiment provides a quartz fiber reinforced silica composite material for a radome, comprising the following steps:

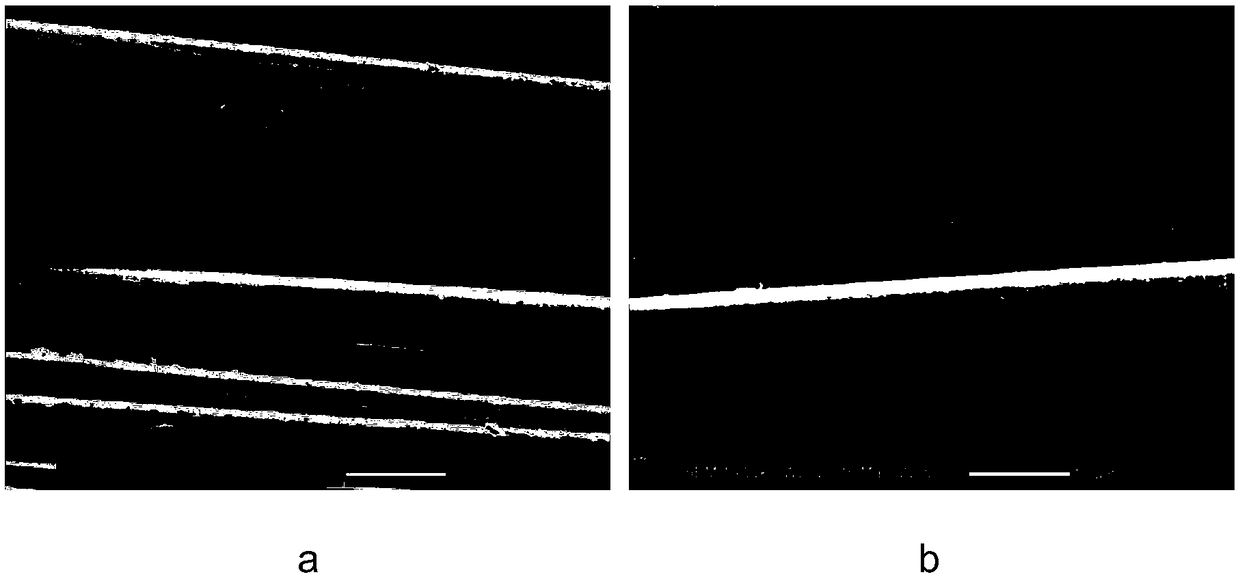

[0048] (1) Use quartz fibers with aluminum coating on the monofilament surface to weave a flat fabric preform with a size of 300×300×30mm, and then heat-treat the fabric preform at a temperature of 600°C and a holding time of 180min , to obtain a fabric prefabricated body with a ceramic coating on the surface of the monofilament, the appearance of which is as follows figure 2 As shown in a; subsequently, the whole fabric preform is immersed in the aluminum sol (diluted by commercially available aluminum sol) with a concentration of 10wt% in the dipping tank, and then the dipping tank is sealed and vacuumed to a vacuum of -0.06MPa , keep it for 120 minutes after reaching the target vacuum degree, return to normal pressure after holding the pressure, take out the fabric; control the drying of the taken out fabric, the drying ...

Embodiment 2

[0051] (1) Use quartz fibers with aluminum coating on the monofilament surface to weave a flat fabric preform with a size of 120×200×20mm, and then heat-treat the fabric preform at a temperature of 700°C and a holding time of 60 minutes ; Subsequently, the fabric prefabricated body is immersed in a concentration of 5wt% aluminum sol (diluted by commercially available aluminum sol) in the impregnation tank as a whole, then the impregnation tank is sealed and vacuumized to a vacuum degree of -0.08MPa to reach the target vacuum After holding the pressure for 100 minutes, return to normal pressure after holding the pressure, take out the fabric; control the drying of the taken out fabric, the drying temperature is 90 ° C, the humidity is controlled at 98% RH, and the drying time is 300 minutes; the dried fabric preform Carry out heat treatment, the heating temperature is 600 ° C, and the heating time is 180 min; through the observation of the scanning electron microscope, no obviou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com