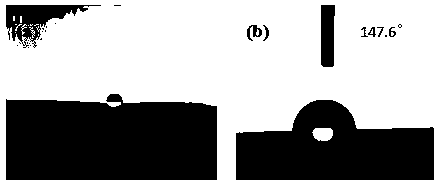

Solvent-free hydrophobic self-repairing polyurethane coating and preparation method thereof

A polyurethane coating and self-repairing technology, which is applied in the field of polyurethane, can solve the problems of using solvents, no self-cleaning, and non-durable coatings, and achieve the effects of increased service life, short repair time, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Mix 0.2 parts of graphene oxide, 1.8 parts of octadecylamine and 120 parts of ethanol, stir and react at 65°C for 22 hours, and dry in vacuum at 60°C to obtain modified graphene oxide;

[0033] Step 2: Under the protection of an inert gas, mix a certain amount of polyisocyanate and polyol evenly, and react at 60°C for 2 hours, measure the content of -NCO in the system to determine the end of the reaction, and prepare an isocyanate-terminated pre-isocyanate with a content of -NCO of 5%. Polymer;

[0034] Step 3: under the protection of an inert gas, add furylamine to the above prepolymer, n (FMA): n (-NCO)=2:1, stirring and reacting at 80°C for 30 minutes, raising the temperature to 90°C and continuing stirring and reacting for 6 hours, so that the content of -NCO in the system is completely consumed, and furan ring-terminated polyurethane is obtained;

[0035] Step 4: under the protection of an inert gas, add bismaleimide to the above furan ring-terminated pol...

Embodiment 2

[0038] Step 1: Mix 0.3 parts of graphene oxide, 2.1 parts of octadecylamine and 150 parts of ethanol, stir and react at 75°C for 24 hours, and dry in vacuum at 60°C to obtain modified graphene oxide;

[0039] Step 2: Under the protection of an inert gas, mix a certain amount of polyisocyanate and polyol evenly, and react at 70°C for 2 hours, measure the content of -NCO in the system to determine the end of the reaction, and prepare an isocyanate-terminated pre-isocyanate with a content of -NCO of 5%. Polymer;

[0040] Step 3: under the protection of an inert gas, add furylamine to the above prepolymer, n (FMA): n (-NCO)=2:1, stirring and reacting at 80°C for 30 minutes, raising the temperature to 90°C and continuing stirring and reacting for 6 hours, so that the content of -NCO in the system is completely consumed, and furan ring-terminated polyurethane is obtained;

[0041] Step 4: under the protection of an inert gas, add bismaleimide to the above furan ring-terminated pol...

Embodiment 3

[0044] Step 1: Mix 0.3 parts of graphene oxide, 2.1 parts of octadecylamine and 150 parts of ethanol, stir and react at 80°C for 24 hours, and dry in vacuum at 60°C to obtain modified graphene oxide;

[0045] Step 2: Under the protection of an inert gas, mix a certain amount of polyisocyanate and polyol evenly, and react at 80°C for 2 hours, measure the content of -NCO in the system to determine the end of the reaction, and prepare an isocyanate-terminated pre-isocyanate with a content of -NCO of 6%. Polymer;

[0046] Step 3: under the protection of an inert gas, add furylamine to the above prepolymer, n (FMA): n (-NCO)=2:1, stirring and reacting at 80°C for 30 minutes, then raising the temperature to 100°C and continuing to stir and react for 6 hours, so that the content of -NCO in the system is completely consumed, and furan ring-terminated polyurethane is obtained;

[0047] Step 4: under the protection of an inert gas, add bismaleimide to the above furan ring-terminated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com