Refuse landfill sealing top layer and preparation method and application thereof

A landfill and functional layer technology, applied in protection devices, buildings, infrastructure projects, etc., can solve the problems of aggravating the shortage of soil resources, reducing the amount of landfill landfill, and difficulty in obtaining materials, so as to alleviate the soil resources. Shortage, the effect of alleviating the situation of soil shortage and saving soil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

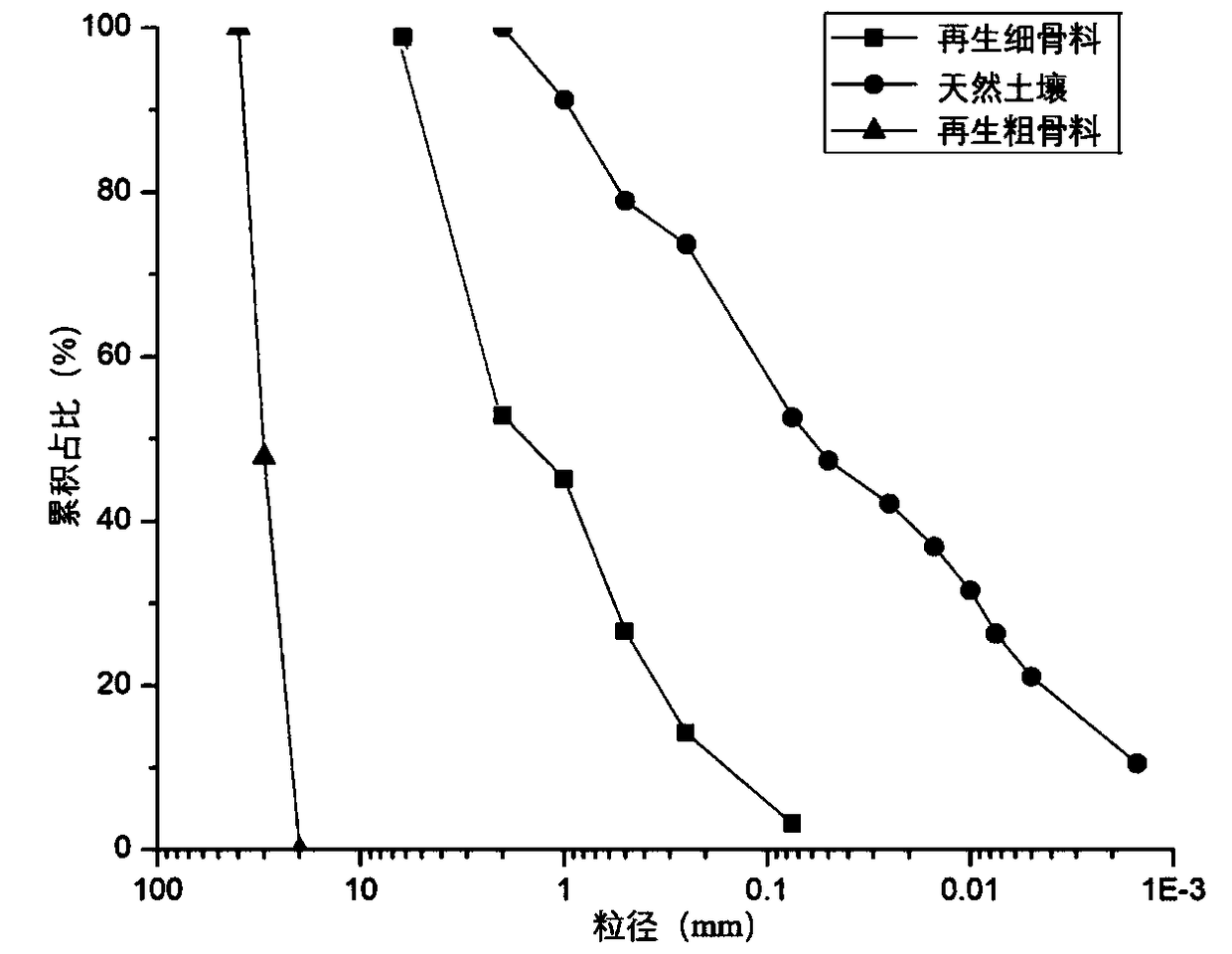

[0057] A topping layer of a landfill, comprising at least three functional layers, the functional layers are sequentially stacked from outside to inside (or from top to bottom): a water storage layer, a drainage layer and a low-permeability layer, The water storage layer is mainly composed of recycled fine aggregate with a particle size of less than 5mm; the drainage layer is mainly composed of recycled coarse aggregate with a particle size of 10mm-40mm; the low permeability layer is mainly composed of natural soil Composition; both the regenerated fine aggregate and the regenerated coarse aggregate are processed from construction waste.

Embodiment 2

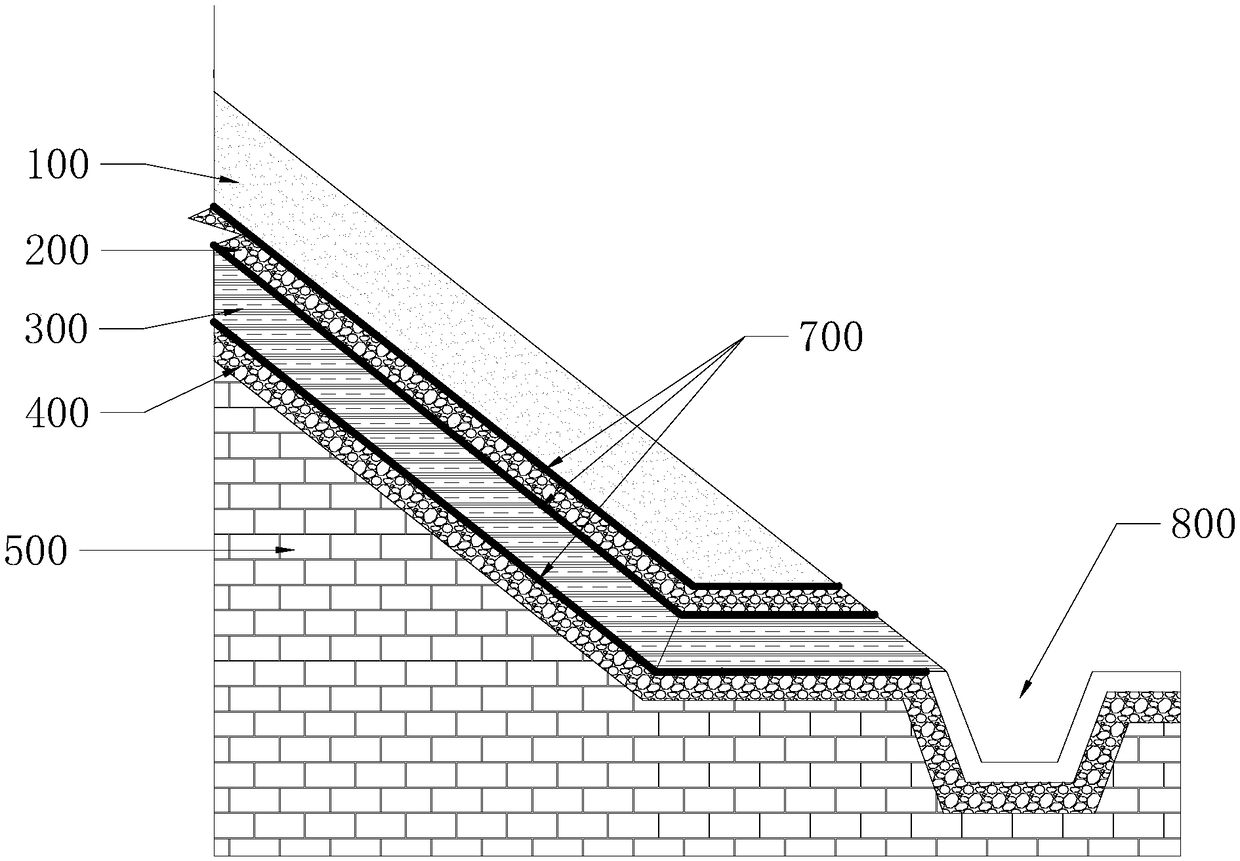

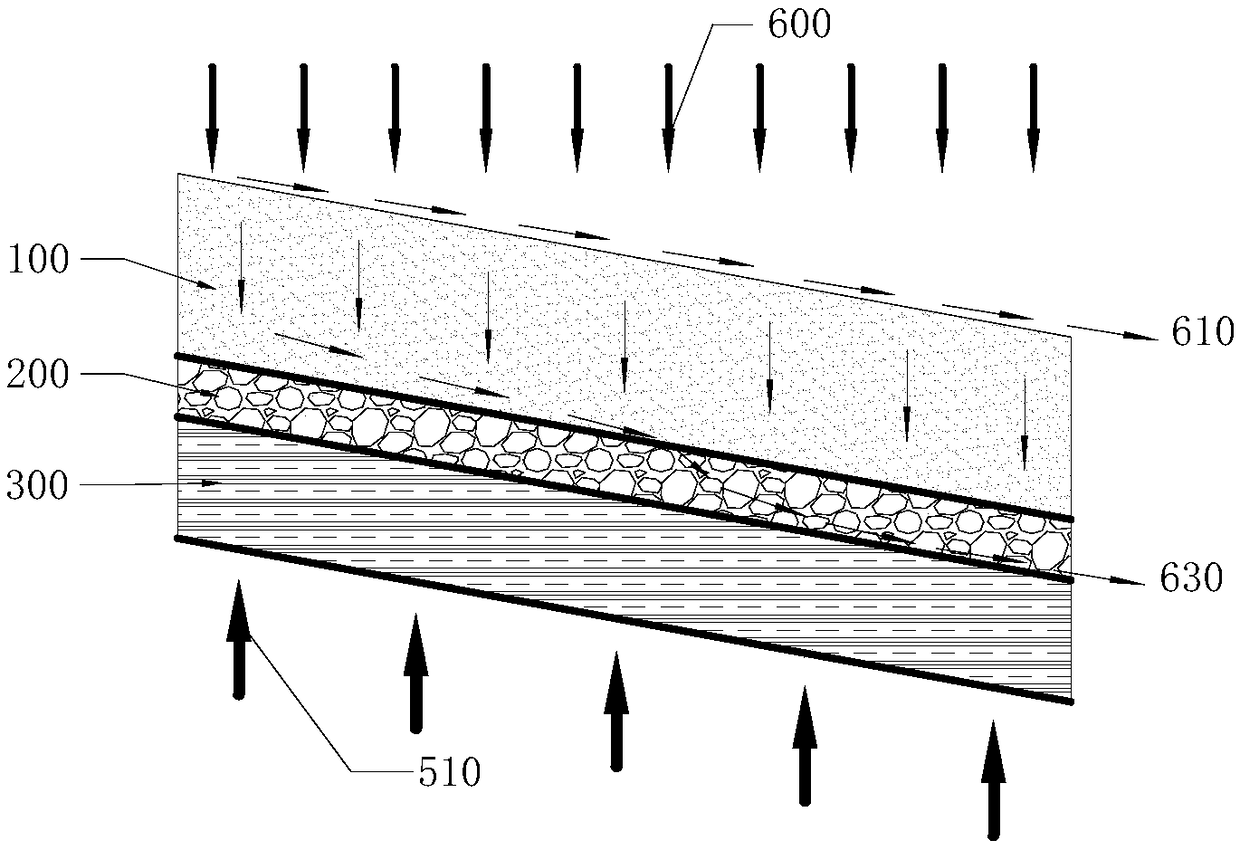

[0059] A landfill topping layer constructed from construction waste. like figure 1 As shown, the topping layer includes four layers of stacked functional layers, and the functional layers are in order from outside to inside (or from top to bottom): water storage layer 100, drainage layer 200, low permeability layer 300, drainage layer An air layer 400, and an insulating material layer 700 is provided between each functional layer.

[0060] The characteristics and requirements of the above functional layers are as follows:

[0061] The water storage layer 100 is constructed of recycled fine aggregate made from crushed construction waste, with a thickness of 1 m. The maximum particle size of recycled fine aggregate is less than 5mm, and its saturated permeability coefficient is determined to be 2×10 -5 m / s~1×10 -4 m / s, and the compaction relative density is 0.9.

[0062] The drainage layer 200 is constructed of recycled coarse aggregate made from crushed construction waste,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com