Corrugated steel-concrete combined support structure and method for constructing same

A technology of supporting structure and construction method, which is applied in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problems of large thickness of lining structure, slow construction speed, poor integrity, etc., to improve construction quality, save engineering costs, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

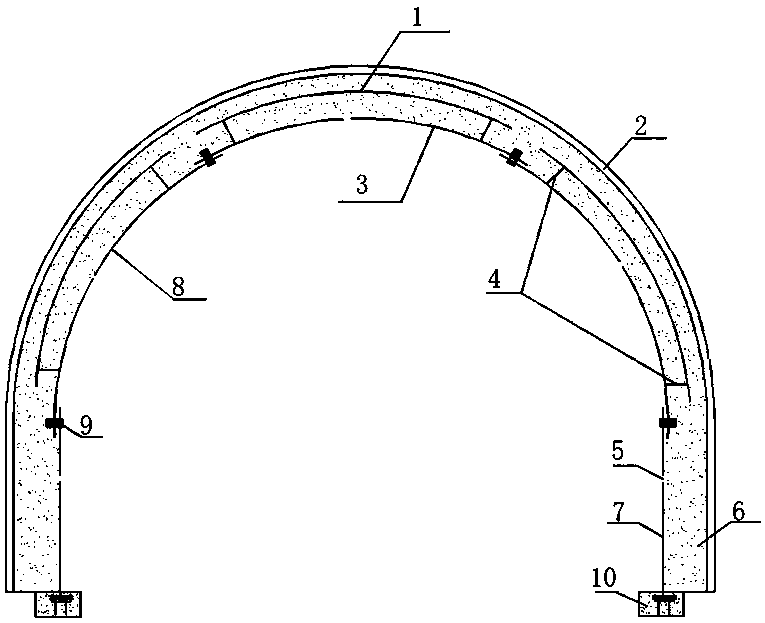

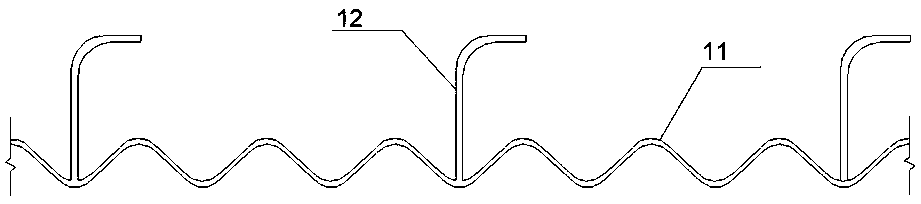

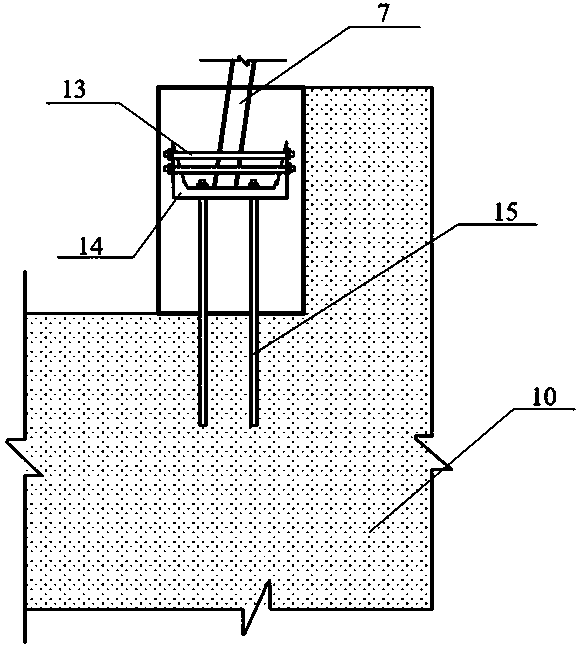

[0030] See attached figure 1 , which is a schematic diagram of a corrugated steel-concrete composite support structure provided in this embodiment. Five steel plates are arranged along the tunnel ring direction, including corrugated steel plates in the circular arch and two corrugated steel plates in the straight wall 7. The corrugated steel plates in the circular arch are The top arched corrugated steel plate 3 and the two side arched corrugated steel plates 8 are connected by corrugated steel plate connecting bolts 9 to form a round arch, and the two side arched corrugated steel plates 8 are respectively connected with two straight wall corrugated steel plates 7 through corrugated The steel plates are connected by connecting bolts 9 to form a corrugated steel support structure; vertical connecting steel bars 4 are provided at the troughs where the two ends of the three circular arch corrugated steel plates are overlapped, and the steel bar 1 is composed of a number of circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com