Water-reactive metal fuel cyclone ramjet steam generator

A steam generator and swirl generator technology, applied in the field of water reaction metal fuel swirl ram steam generator, can solve the problems of limited use, low steam quality, environmental pollution, etc., and achieve ingenious device design, steam The effect of high quality and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

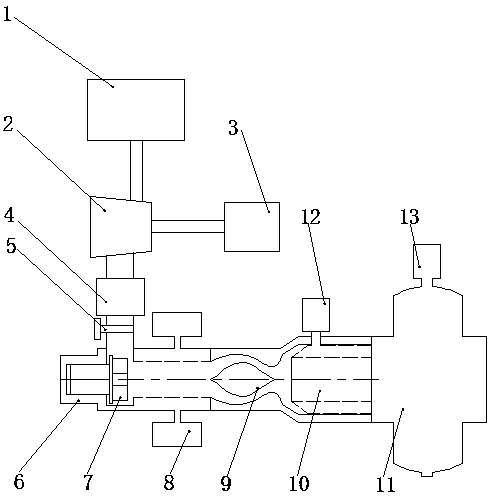

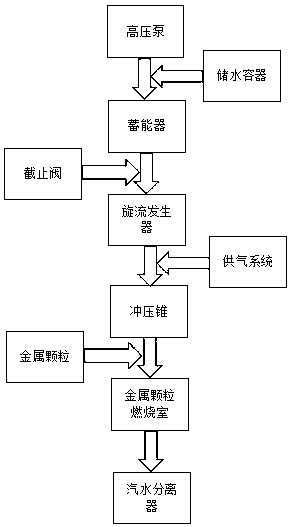

[0039] As shown in the figure, the device includes a water storage container, a high-pressure pump, a high-pressure power system, a water pressure stabilization unit, a casing, a swirl generator, an air supply system, a stamping cone, a combustion chamber, a steam-water separator, and a supply of metal particles The system, the hydrogen collecting device, the swirl generator, the stamping cone, and the combustion chamber are sequentially arranged in the casing. In this embodiment, the water pressure stabilization unit includes an accumulator and a stop valve.

[0040] Wherein, the water storage container is connected with the high-pressure pump, and the high-pressure pump is connected with the high-pressure power system, and the high-pressure power system can provide driving power for the high-pressure pump. At the same time, the high-pressure pump, the accumulator and the swirl generator in the casing are connected in sequence, and the water output by the high-pressure pump f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com