Testing method for dispersion uniformity of additives in lead-acid battery negative lead paste

A lead-acid battery and detection method technology, applied in the field of detecting the dispersion uniformity of additives in negative lead paste, and detecting the dispersion uniformity of additives in lead paste, which can solve the problems of complex components, identification of uniformity errors of lead paste, and time-consuming problems, etc. , to achieve the effect of easy experimental operation, improved accuracy and simple mathematical calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

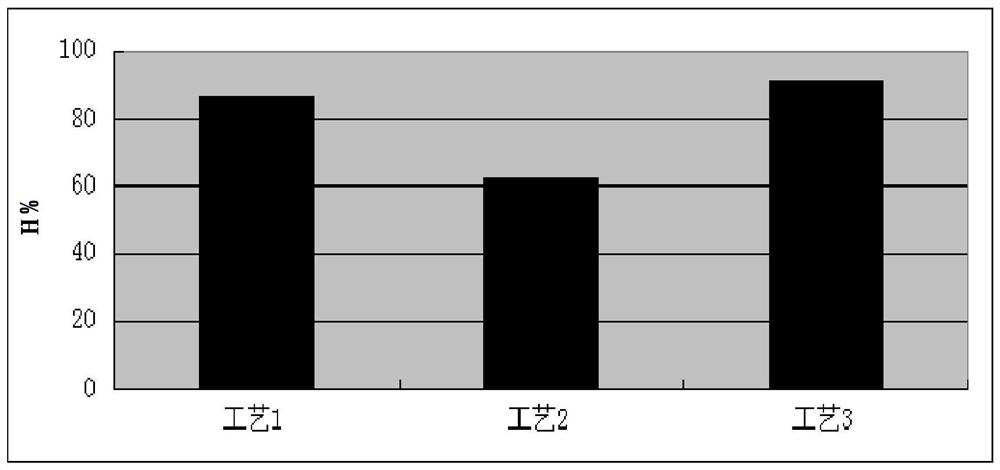

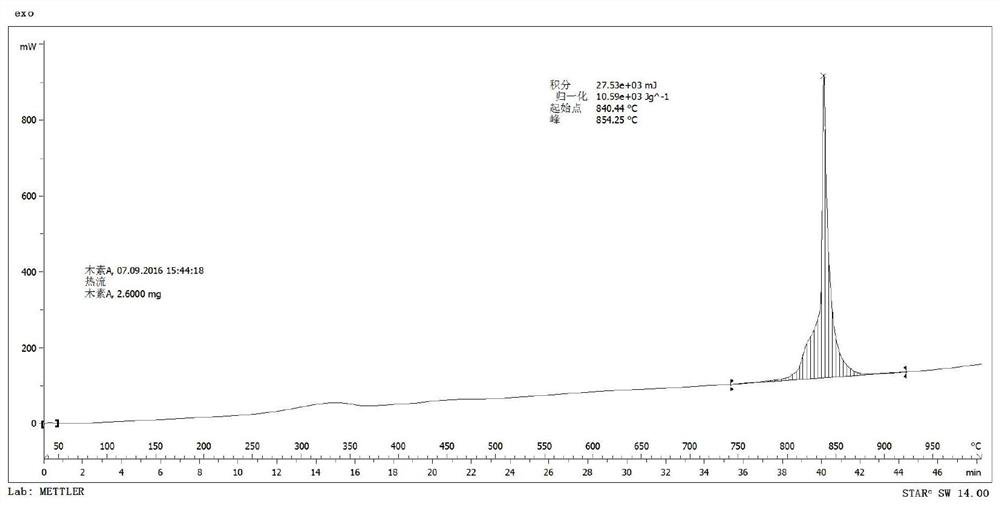

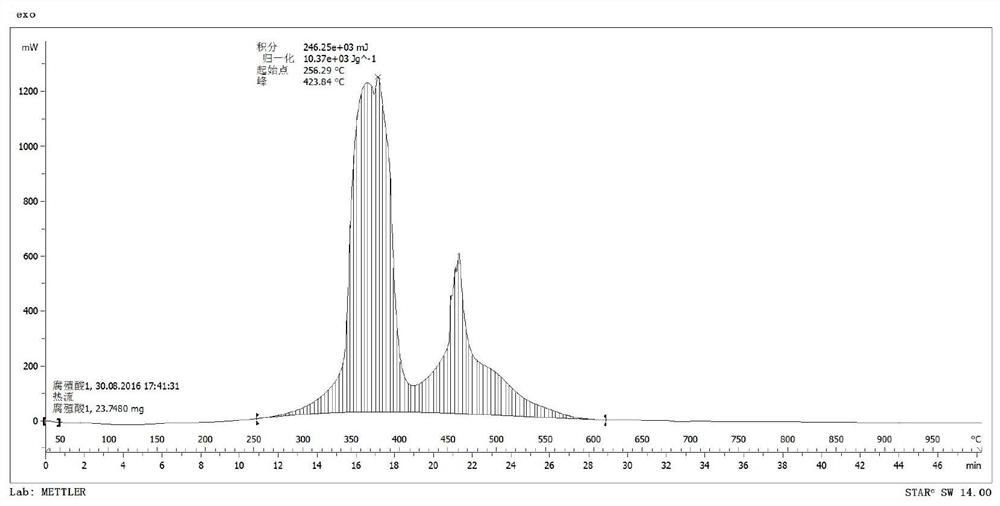

[0030] The present invention uses a DSC / TGA synchronous analyzer to detect the distribution uniformity of additives in lead paste, and finds out the exothermic peak of the additive in the DSC curve through positive and negative plate blank comparison, and integrates the exothermic peak of the additive, and the integrated area is the additive The total heat release, which is divided by the total weight of the sample to obtain the heat release per gram of sample, that is, the heat release of additives per gram of sample. According to the average value, standard deviation, dispersion, uniformity and homogenization effect and other indicators to comprehensively judge the consistency of the chemical composition of the lead paste.

[0031] The detection method of the present invention is further described below in conjunction with embodiment:

[0032] Sample preparation: After the preparation of the lead paste is completed, take out 10 wet negative raw boards at the same intervals f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com