Electromagnetic active compensator of a yarn loop at a workstation of a textile machine and controlling method thereof

An active compensation, textile machine technology, applied in the direction of thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problem that the signal of the sensor is not described in detail to be processed, does not allow compensation arm trajectory and force adjustment, can Limited controllability and other issues, to achieve the effect of simple structure, small space requirement, and precise movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

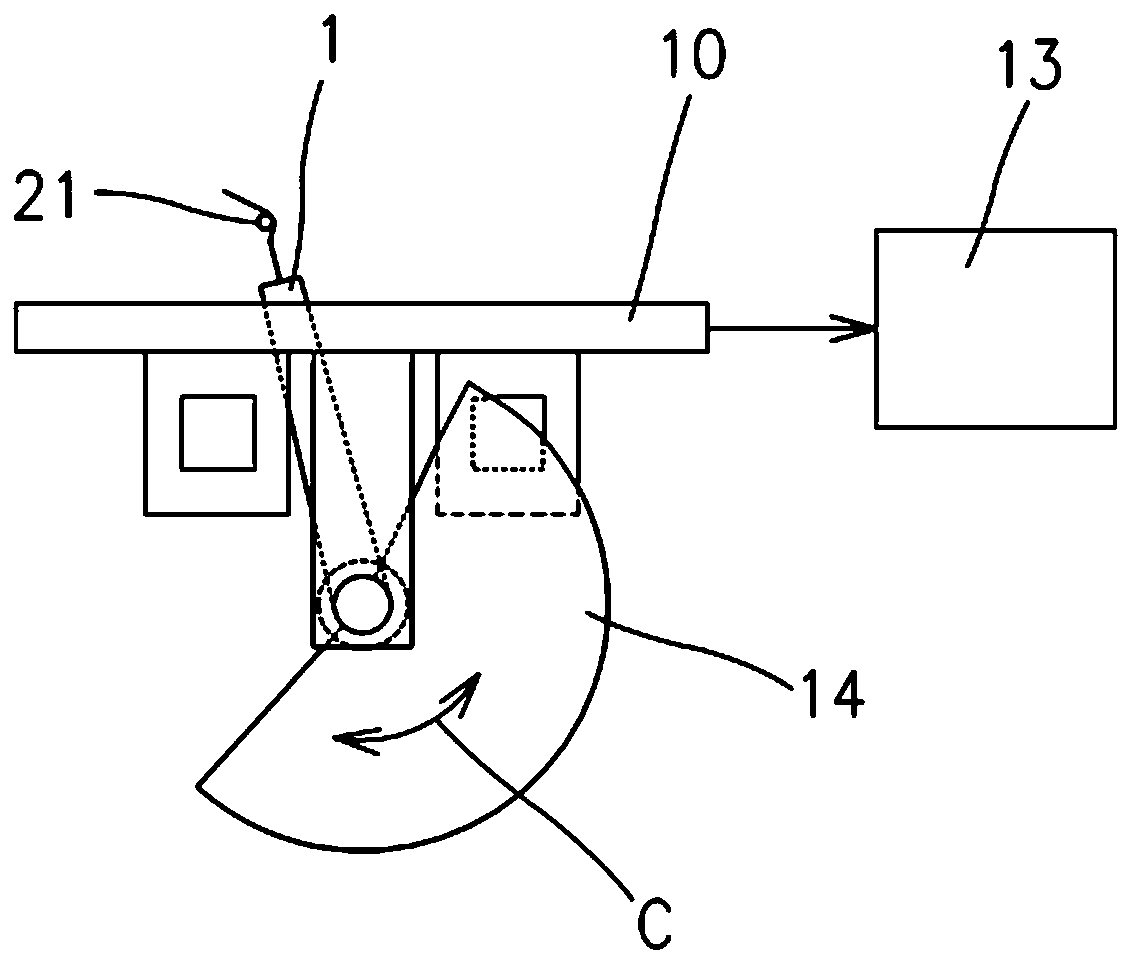

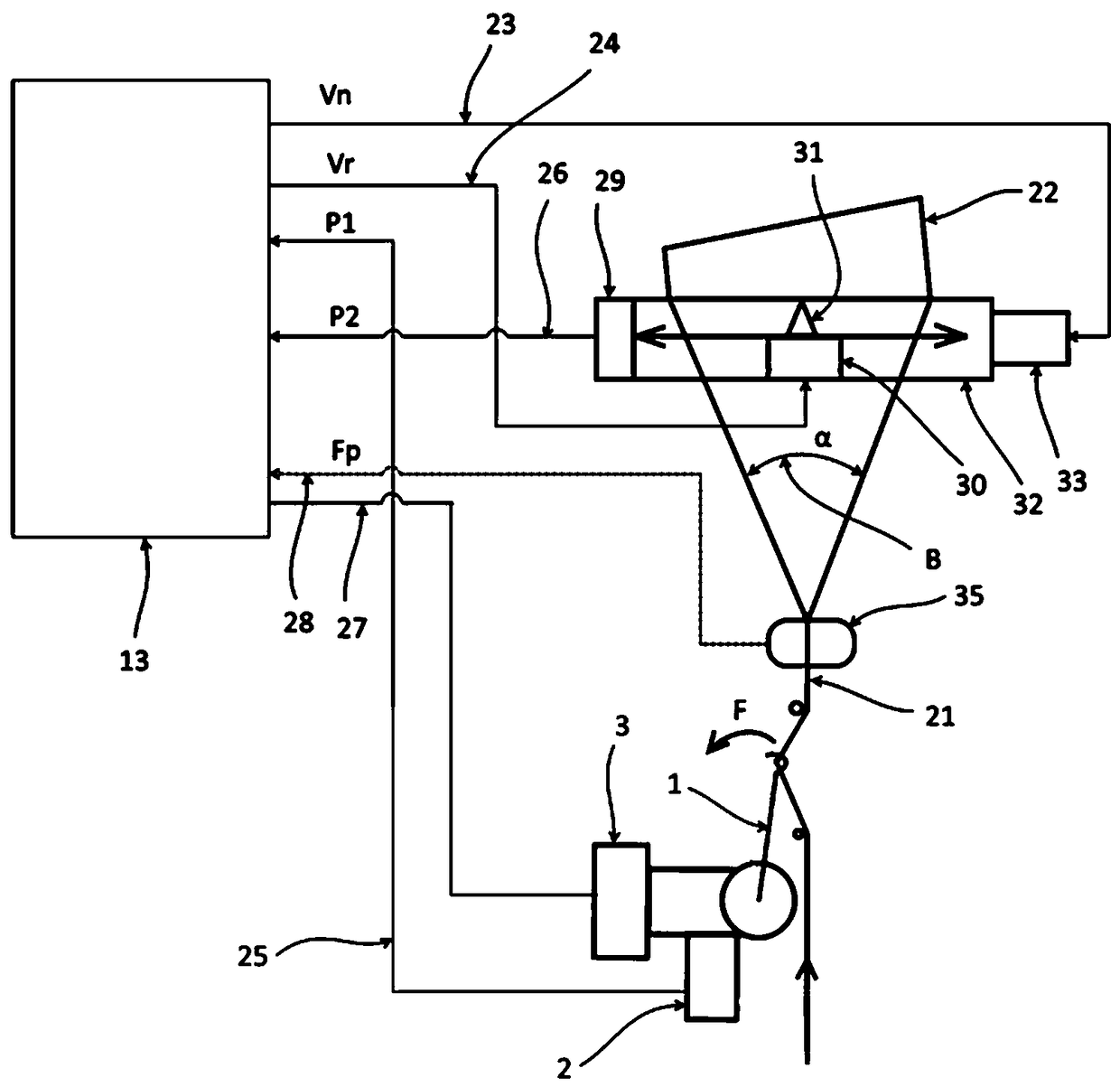

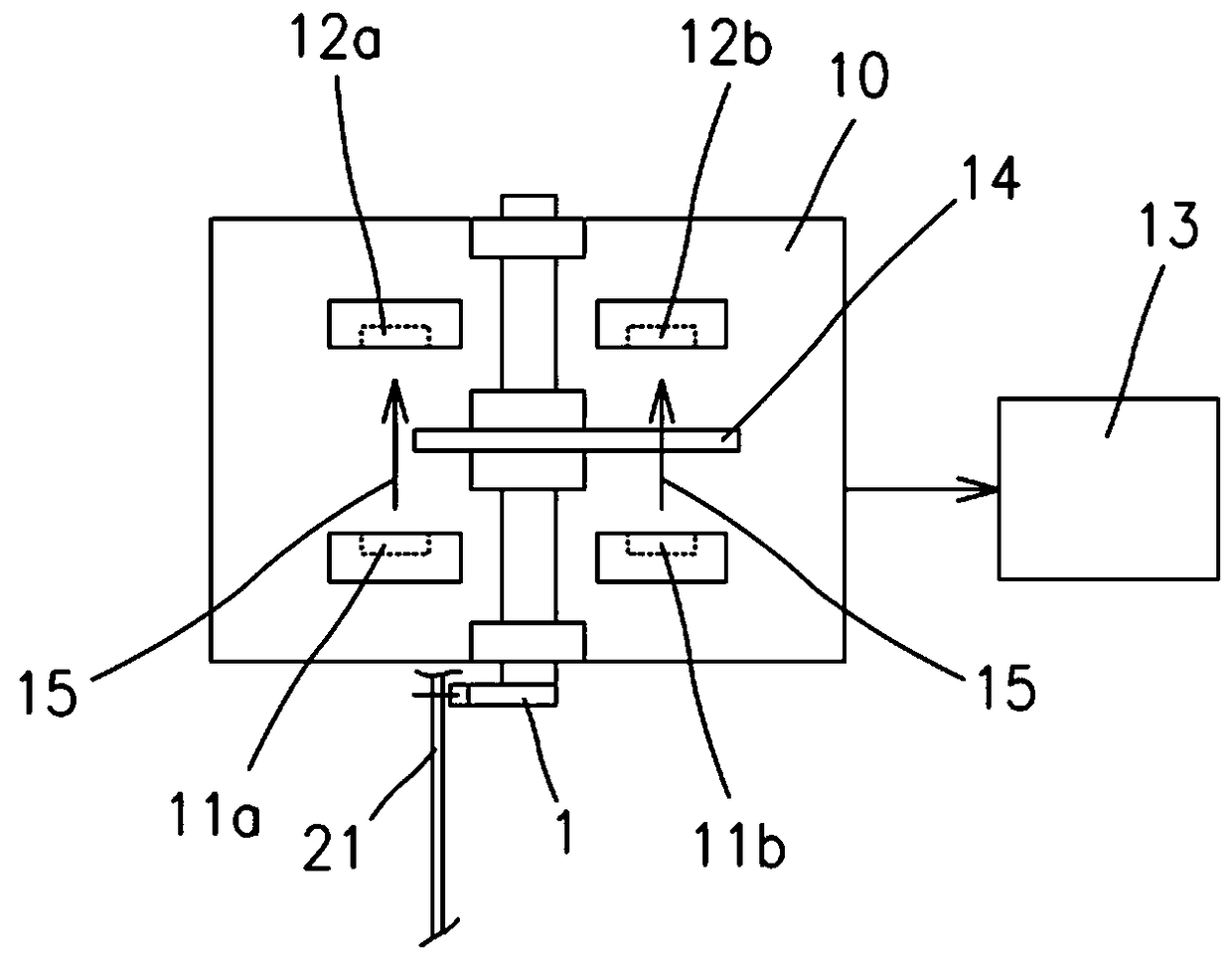

[0025] The invention will become clear from the description of an example embodiment of an active yarn loop compensator with a position sensor of a compensating arm and from the description of an example of controlling this compensator at the workbench of a spinning machine, wherein the compensator is arranged In the section between the yarn drawing mechanism from the spinning unit and the yarn winding device on the cross-winding bobbins.

[0026] Workbenches for spinning machines like this are well known, and therefore, for the sake of completeness, they will be described here only symbolically, without drawings. The spinning machine comprises at least one row of identical tables arranged next to each other, wherein each table comprises a spinning unit in which the yarn is formed. The yarn is drawn from the spinning unit by a yarn drawing mechanism comprising a known pair of drawing rollers between which the yarn passes and which are rotatably mounted on the machine frame mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com