Heat-conductive electromagnetic-shielding polypropylene composite material and preparation method of same

A composite material and electromagnetic shielding technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as complex construction, high density, and difficult molding, and achieve high equipment efficiency, excellent processing performance, and improved thermal conductivity. The effect of electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

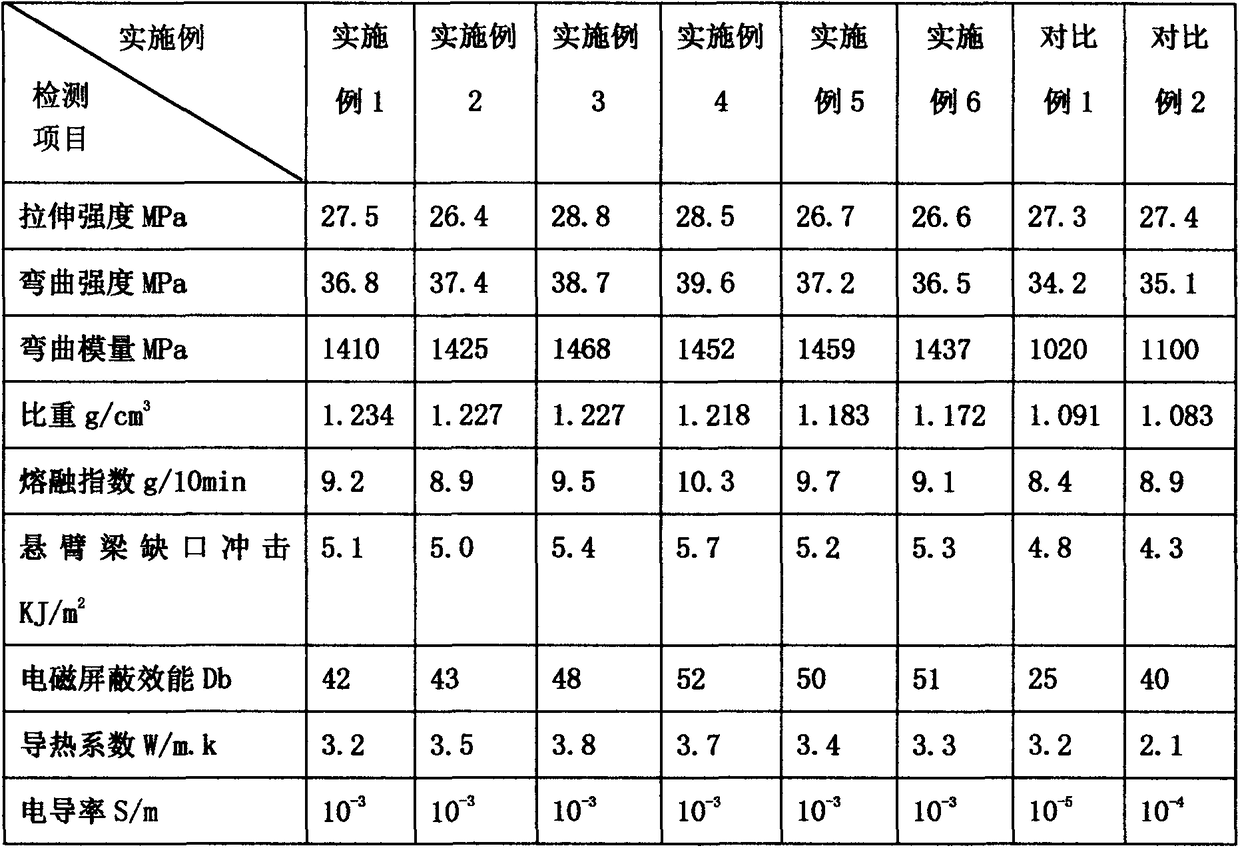

Examples

Embodiment 1

[0026] A heat-conducting electromagnetic shielding polypropylene material component and weight percent are 53 parts of pp resin, 5 parts of PE, 20 parts of silicon carbide, 15 parts of nanoscale graphene with a particle size of 10mm, 0.5 parts of antioxidant 168 and 1010, 1.5 parts lubricant, 5 parts compatibilizer.

[0027] Prepare the modified polypropylene material of the thermally conductive electromagnetic shielding material as follows:

[0028] A, take each raw material by weighing raw material ratio;

[0029] B, the polypropylene resin that will take by weighing, toughening agent, compatibilizer are mixed in high-speed mixer;

[0030] C. Add antioxidant and lubricant, and add conductive agent and thermal conductive agent through side feeding, and further mix evenly;

[0031] D. Send the mixed material to the twin-screw extruder for extrusion. The extrusion temperature is: the temperature of the first zone is 181°C, the temperature of the second zone is 198°C, the temp...

Embodiment 2

[0034] The mass composition ratio of a thermally conductive electromagnetic shielding polypropylene material is as follows: 52 parts of pp resin, 5 parts of PE, 19 parts of magnesium oxide, 17 parts of nano-scale carbon nanotubes with a diameter of 20 mm, and 0.5 parts of antioxidant 1010 , 1.5 parts of lubricant, 5 parts of compatibilizer.

[0035] Prepare the modified polypropylene material of the thermally conductive electromagnetic shielding material as follows:

[0036] A, take each raw material by weighing raw material ratio;

[0037] B, the polypropylene resin that will take by weighing, toughening agent, compatibilizer are mixed in high-speed mixer;

[0038] C. Add antioxidant and lubricant, and add conductive agent and thermal conductive agent through side feeding, and further mix evenly;

[0039] D. Send the mixed material to the twin-screw extruder for extrusion. The extrusion temperature is: the temperature of the first zone is 183°C, the temperature of the secon...

Embodiment 3

[0042] The mass composition ratio of a thermally conductive electromagnetic shielding polypropylene material is as follows: 51 parts of pp resin, 5 parts of PE, 18 parts of alumina, 19 parts of carbon fiber with a diameter of 2 mm, 0.5 parts of antioxidant 1098, and 1.5 parts of lubricating agent, 5 parts of compatibilizer.

[0043] Prepare the modified polypropylene material of the thermally conductive electromagnetic shielding material as follows:

[0044] A, take each raw material by weighing raw material ratio;

[0045] B, the polypropylene resin that will take by weighing, toughening agent, compatibilizer are mixed in high-speed mixer;

[0046] C. Add antioxidant and lubricant, and add conductive agent and thermal conductive agent through side feeding, and further mix evenly;

[0047] D. Send the mixed material to the twin-screw extruder for extrusion. The extrusion temperature is: the temperature of the first zone is 185°C, the temperature of the second zone is 201°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com