One-step preparation method for white light-emitting carbon dots

A technology of carbon dots and white light, applied in the field of luminescent nanomaterials, can solve the problems of difficulty in uniform dispersion, consumption of rare earth resources, and difficulty in control, and achieves safe and efficient methods, simple processes, and the effects of light-emitting and encapsulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The carbon dots emitting white light were prepared as follows:

[0031] 1. Weigh 0.254g of o-phenylenediamine and 0.255g of catechol, put them in a 20mL reaction kettle, add 10mL of n-amyl alcohol into it, put them in an oven, heat up to 200°C, keep warm for 12 hours, and cool naturally. A solution of carbon dots emitting white light was obtained.

[0032] 2. Take out the solution obtained in step 1 and place it in uniformly stirred hot water at 85°C that is 10 times the volume of the reacted solution, heat and stir for 3 hours, and fully dissolve the incompletely reacted reactants in the hot water. Put this liquid in a centrifuge tube, centrifuge at 5000 rpm for 10 minutes, and take the lower layer of sediment.

[0033] 3. Redisperse the lower precipitate obtained in step 2 into ethanol with 3 times the volume of the solution after the reaction, and sonicate for 30 minutes.

[0034] 4. The liquid obtained in step 3 was rotary evaporated, and the solid in the lower la...

Embodiment 2

[0042] The preparation method of white light LED is as follows:

[0043]1. Weigh 5 μg of the white carbon dot prepared in Example 1 and place it in a 4 mL small plastic tube, add 25 μL of tetraethylenepentamine to it to obtain a transparent and clear solution, then add 125 μL of epoxy resin, and mix well.

[0044] 2. Drop a drop of the mixture in step 1 on the LED chip whose emission peak is at 365nm, and let it stand at room temperature for 6 hours until it solidifies.

[0045] 3. The LED emits white light under the excitation of 365nm.

[0046] Figure 7 It is a picture of the white light LED device prepared in Example 2.

PUM

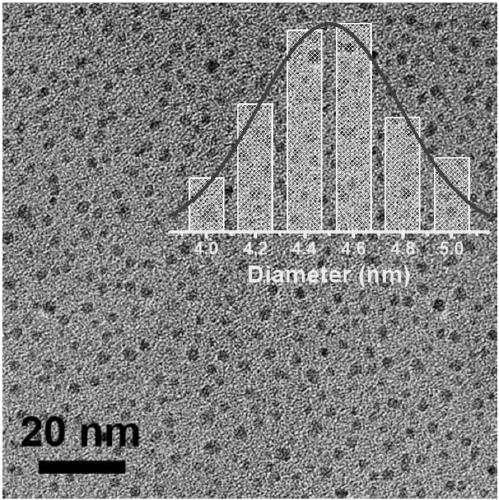

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com