Preparation method of nickel sulfide nanosheet array

A technology of nanosheet array and nickel sulfide, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of raw material consumption and achieve the effects of simplified preparation process, good catalytic performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Drop-coating thiolamine solution on nickel foam

[0027] Dissolve ethylenediamine and ethanedithiol in a volume ratio of 4:1 to make a thiolamine solution, and apply 0.5mL of thiolamine solution to 1*1cm 2 on the surface of one side of the nickel foam;

[0028] (2) Preparation of nickel foam supported nickel sulfide

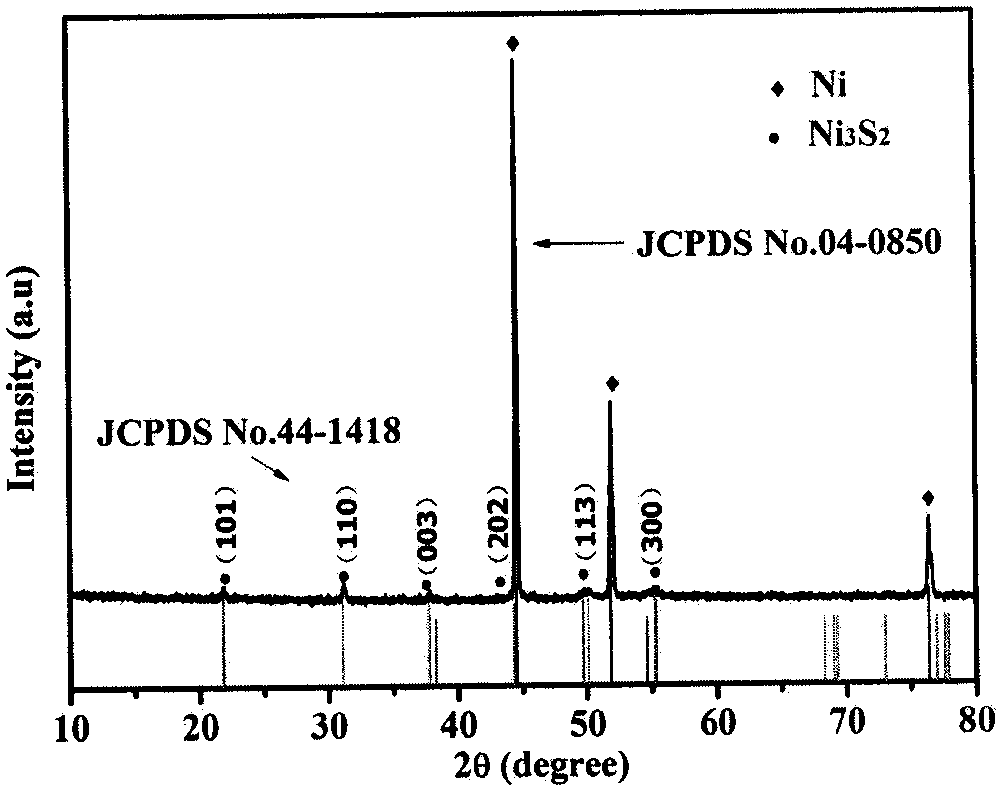

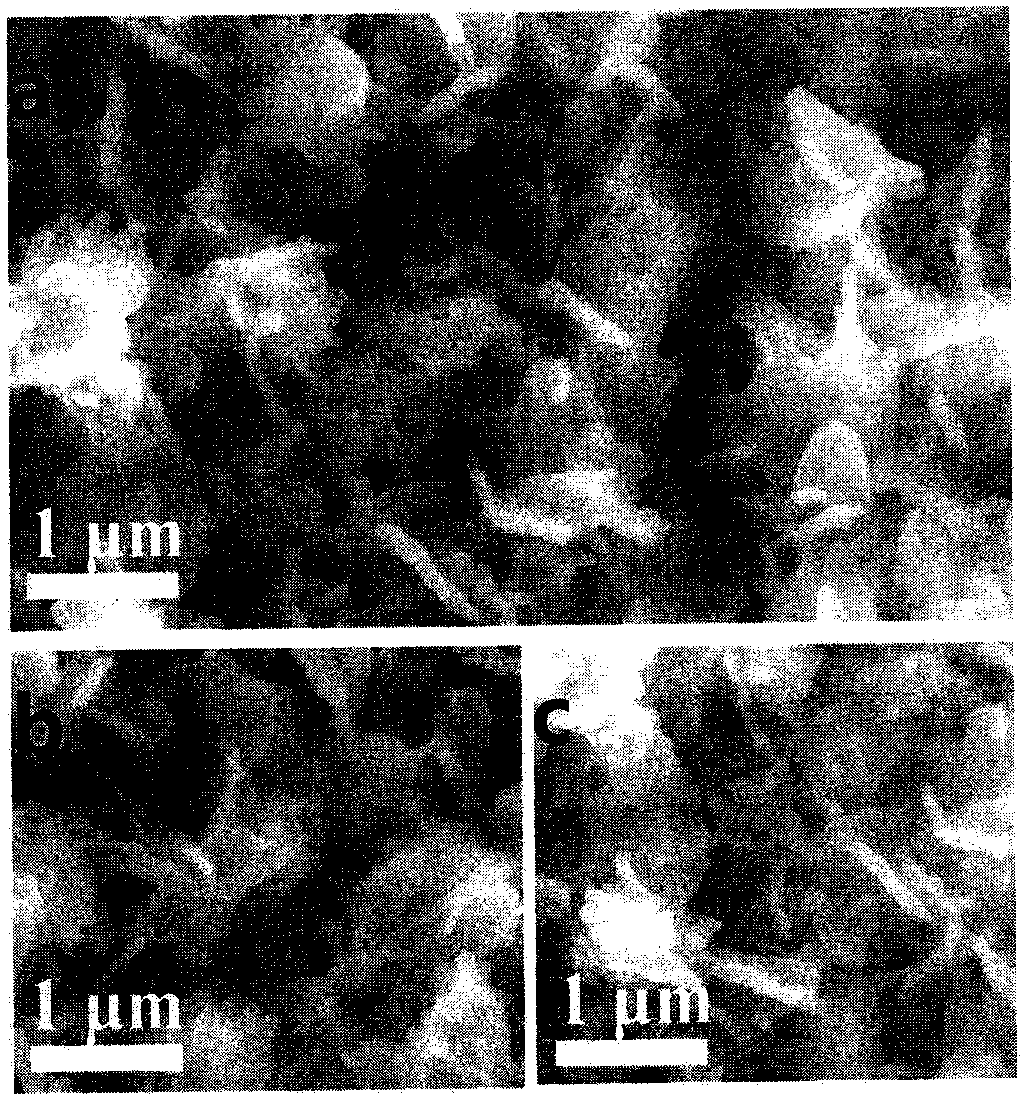

[0029] The nickel foam that had been drip-coated with the thiolamine solution in step (1) was allowed to stand at room temperature and pressure for 24 hours, then the sample was placed on a heating plate, and heated at 300°C for 60 s, and finally the foamed nickel-supported nickel sulfide nanosheet array was obtained (Ni 3 S 2 NFs / NFs). X-ray diffraction pattern ( figure 1 ) in (101), (110), (003), (202), (113), (300) corresponding to the standard card JCPDS No.44-1418 respectively, proved to be pure phase nickel sulfide, indicating that The invented method can be used to prepare phase-pure nickel sulfide (Ni 3 S 2 ); where the three strongest ...

Embodiment 2

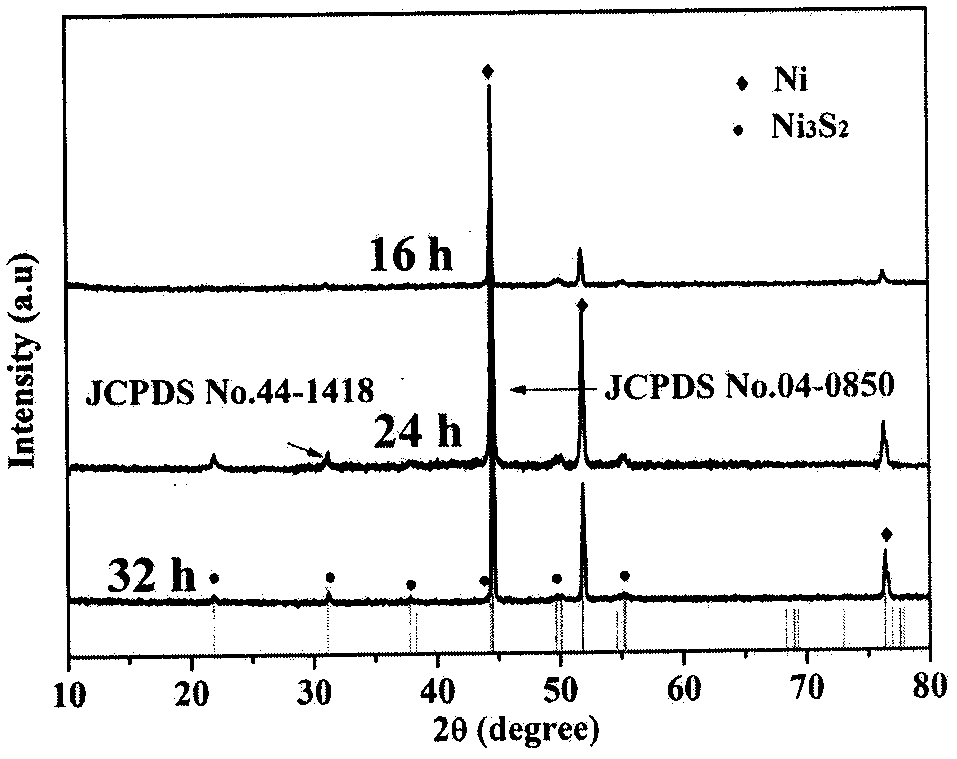

[0031] The other steps are the same as in Example 1, except that the resting time under normal temperature and pressure is changed from 24h to 16h. As a result, an array of nickel sulfide nanosheets is also obtained, but the thickness of the nanosheets is about 120nm, and the size is about 1.5μm , and the gap spacing of the nanosheet array is about 300nm, the specific shape is as follows image 3 As shown in b; when the prepared sample is applied to electrocatalysis, its OER overpotential is 280mV, which is 50mV lower than the OER overpotential of the nickel sulfide nanosheet array prepared by the Tewodros Asefa research group using the hydrothermal method. The specific polarization curve of the sample is as Figure 4 shown by the green line.

Embodiment 3

[0033] The other steps are the same as in Example 1, except that the standing time under normal temperature and pressure is changed from 24h to 32h. As a result, an array of nickel sulfide nanosheets is also obtained, but the thickness of the nanosheets is about 150nm, and the size is about 1.3μm. , and the gap spacing of the nanosheet array is about 500nm, the specific shape is as follows image 3 As shown in c; when the prepared sample is applied to electrocatalysis, its OER overpotential is 300mV, which is 30mV lower than the OER overpotential of the nickel sulfide nanosheet array prepared by the Tewodros Asefa research group using the hydrothermal method. The specific polarization curve of the sample is as Figure 4 shown by the blue line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com