A method of quickly obtaining ore using impact crushing

A technology of impact crushing and impact crushing, which is applied in the direction of grain processing, etc., can solve the problems of large equipment investment, high crushing energy consumption, and low crushing efficiency, and achieve the effect of simplifying the process, shortening the process, and improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

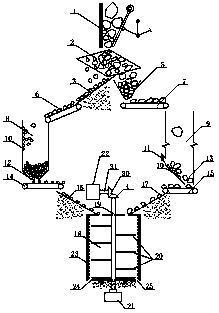

[0031] A method for quickly obtaining ore using impact crushing, including jaw crusher 1, coarse screen 2, throwing impact crushing bin 8, falling ore impact crushing bin 9 and impact crushing bin 18. A coarse crusher is provided below the outlet of jaw crusher 1. Screen 2, ore hopper A5 is set on the lower right side of coarse screen 2, and vibrating screen A3 is set on the lower left side of coarse screen 2. The left exit of vibrating screen A3 is movably connected to the right side of the inclined throwing belt conveyor 6, and the inclined throwing belt conveys The left side of the machine 6 is fixedly connected with the upper right side of the throwing impact crushing bin 8. The bottom end of the throwing impact crushing bin 8 is fixedly connected with the upper end of the ore drawing hopper B12. The lower end of the ore drawing hopper B12 is equipped with a horizontal belt conveyor B14 and a horizontal belt conveyor. A vibrating screen B16 is provided under the right end of...

Embodiment 2

[0036] Example 2: Based on Example 1 but with a difference;

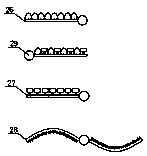

[0037] The left and right sides of the main shaft 19 of the crusher are fixedly connected to the inner end of the impact crushing rod 20. There are four impact crushing rods 20. The impact crushing rod 20 is composed of spherical manganese steel brazing medium 26, spherical manganese steel brazing and manganese in turn from top to bottom. Steel square hammer mixed media 29, manganese steel square hammer media 27 and sawtooth media 28 are made of four media; the top of the grinder main shaft 19 is fixedly connected with the axis of the driven gear 4, and the driven gear 4 is meshed and connected with the transmission gear 30 to drive The axis of the gear 30 is fixedly connected to the right end of the transmission shaft 31, the left end of the transmission shaft 31 is fixedly connected to the right end of the auxiliary motor 22, the auxiliary motor 22 is arranged on the upper left side of the impact crushing chamber 18; ...

Embodiment 3

[0039] Embodiment 3: Based on Embodiments 1 and 2, but the difference is;

[0040] S1. The raw magnetite ore is crushed by the jaw crusher 1 and then enters the coarse screen 2, the large pieces on the screen enter the falling impact crushing bin 9, and the small pieces and mineral powder under the screen enter the throwing impact after being sieved by the vibrating screen A3 Broken warehouse 8;

[0041] S2. The products of throwing impact crushing bin 8 and falling ore impact crushing bin 9 are sieved on vibrating screen B16 and vibrating screen C17 respectively. The fine ore under the screen enters the beneficiation, and the products on the screen enter the impact crushing bin 18;

[0042] S3. The impact crushing bin 18 adopts a layered impact crushing method. The crushing medium on the impact crushing rod 20 imposes point, line, surface and combination impact loads on the ore to capture the impact ore;

[0043] S4. The impact crushing rod 20 at the bottom of the crusher main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com