Industrial robot control system and method based on ethercat bus

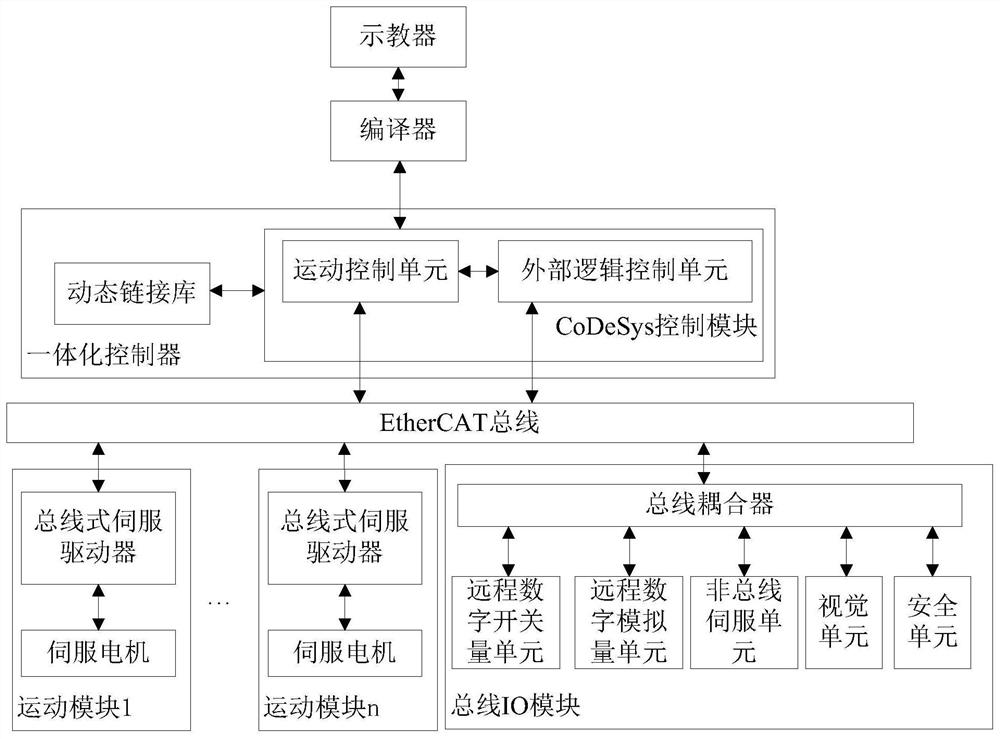

An industrial robot and control system technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of poor reliability, difficult integration, high price, etc., to improve scalability and stability, ensure real-time performance and reliability , The effect of reducing the cost of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0064] Industrial robots based on EtherCAT bus, including the following steps:

[0065] B1, after the bus IO module acquires the switching information of the user input, send the switch information to the CodeSys control module.

[0066] B2, the CODESYS control module receives the switching information, and then calls the preset function from the dynamic link library according to the preset execution information, and obtains the motion parameters to the bus servo drive by EtherCAT bus according to the function of the robot. ;

[0067] B3, the bus servo driver rotates according to the motion parameter control servo motor.

[0068] The user inputs the switch information by the automated control device, the switch information transmits to the integrated controller through the EtherCAT bus, and the CodeSys control module in the integrated controller selects the corresponding mode of operation, and activates the robot. During the CodeSys control module control, implement the function o...

Embodiment 3

[0070] like figure 2 As shown, an industrial robot control method based on the EtherCAT bus, including the following steps:

[0071] A1, after the teaching device obtains the control information input by the user, send the control information to the compiler.

[0072] A2, the compiler acquires the execution information after encoding the control information, and issues the execution information to the CodeSys control module. The control information includes at least one of a linear motion instruction, a point-to-point motion command, an arc motion command, a conditional selection instruction, a program call, a welding instruction, and a palletizing instruction.

[0073] A3, after the bus IO module acquires the switch information of the user input, send the switch information to the CodeSys control module.

[0074] A4, the CODESYS control module receives the switch information, and then calls the preset function from the dynamic link library according to the preset execution inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com