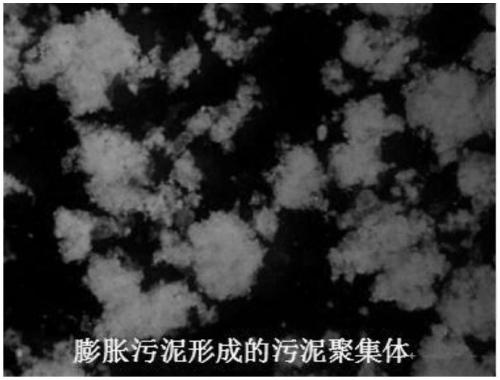

Method for rapidly controlling sludge expansion and keeping long-term stability by forming sludge aggregates

A rapid control and sludge bulking technology, applied in water/sludge/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve problems that have not been reported, and achieve simple and convenient operation and long-term normal operation , the effect is fast and obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for rapidly controlling sludge bulking and long-term stability by forming sludge aggregates, comprising the following steps:

[0029] (1) Take 1L of bulky sludge concentrated by gravity to a sludge concentration of 1g / L, and the SVI of the sludge 30 is 300mL / g;

[0030] (2) adding 0.05g of chitosan with a dry sludge mass of 5% to the sludge in step (1);

[0031] (3) Using a mechanical mixer with a rotating speed of 50rpm, the sludge and chitosan were stirred evenly, then 10ml of glacial acetic acid (the concentration of acetic acid was 1%) was added, and the stirring was continued for 2min at 50rpm;

[0032] (4) drip the NaOH solution of 4mol / L after step (3), adjust pH to 10;

[0033] (5) Stop stirring after step (4), pour out the supernatant after precipitation for 30 minutes, and wash and soak the sludge aggregates with tap water for 3 times, each soaking time is 2h, and the collected sludge aggregates are returned to the reactor after SVI 5 125mL / g, SVI ...

Embodiment 2

[0035] A method for rapidly controlling sludge bulking and long-term stability by forming sludge aggregates, comprising the following steps:

[0036] (1) Take 1L of bulky sludge concentrated by gravity to a sludge concentration of 3g / L, and the SVI of the sludge 30 is 250mL / g;

[0037] (2) adding 0.3 g of chitosan with 10% dry sludge mass to the sludge in step (1);

[0038] (3) Using a mechanical mixer with a rotating speed of 300rpm, the sludge and chitosan were stirred evenly, then 15ml of glacial acetic acid (the concentration of acetic acid was 1.5%) was added, and the stirring was continued at 300rpm for 2min;

[0039] (4) drip the NaOH solution of 3mol / L after step (3), adjust pH to 8;

[0040] (5) Stop stirring after step (4), pour out the supernatant after precipitation for 15 minutes, and wash and soak the sludge aggregates with tap water for 3 times, each soaking time is 1.5h, the collected sludge aggregates are returned to the reactor after SVI 5 105mL / g, SVI 30...

Embodiment 3

[0042] A method for rapidly controlling sludge bulking and long-term stability by forming sludge aggregates, comprising the following steps:

[0043] (1) Take 1 L of bulk sludge that is centrifuged and concentrated to a sludge concentration of 6 g / L, and the SVI of the sludge is 30 is 400mL / g;

[0044] (2) adding 1.2 g of chitosan with a dry sludge mass of 20% to the sludge in step (1);

[0045] (3) Using a mechanical mixer with a rotating speed of 600rpm, the sludge and chitosan were stirred evenly, then 20ml of glacial acetic acid (the concentration of acetic acid was 2%) was added, and the stirring was continued at 600rpm for 2min;

[0046] (4) drip the NaOH solution of 5mol / L after step (3), adjust pH to 9;

[0047] (5) Stop stirring after step (4), pour out the supernatant after precipitation for 25 minutes, and wash and soak the sludge aggregates with tap water for 3 times, each soaking time is 2.5h, the collected sludge aggregates are returned to the reactor after SVI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com