Process for extracting trilobatin from lithocarpus litseifolius

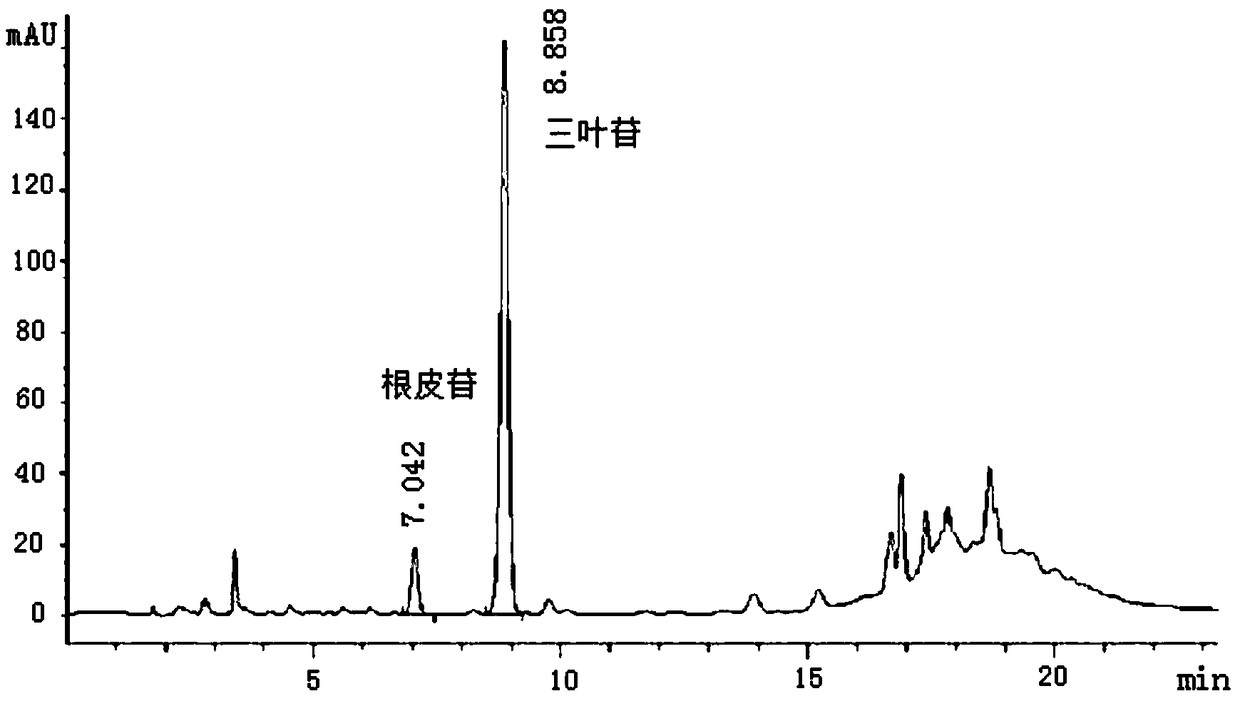

A technology of Cordyceps sinensis and trilobatin, which is applied in the field of monomer separation, can solve problems such as no reports, and achieve the effects of reducing scum, cumbersome operation, and simple and convenient separation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A process for extracting trilobatin from Fructus Alba lanceolata, comprising the following steps:

[0041] S1: Raw material crushing: select the tender leaves of Mujiraecho produced in April, coarsely pulverize them with a pulverizer to obtain Mujiraeba granules, and sieve the obtained Mujiraeba granules through a 10-mesh sieve to obtain Mujiraecho coarse powder;

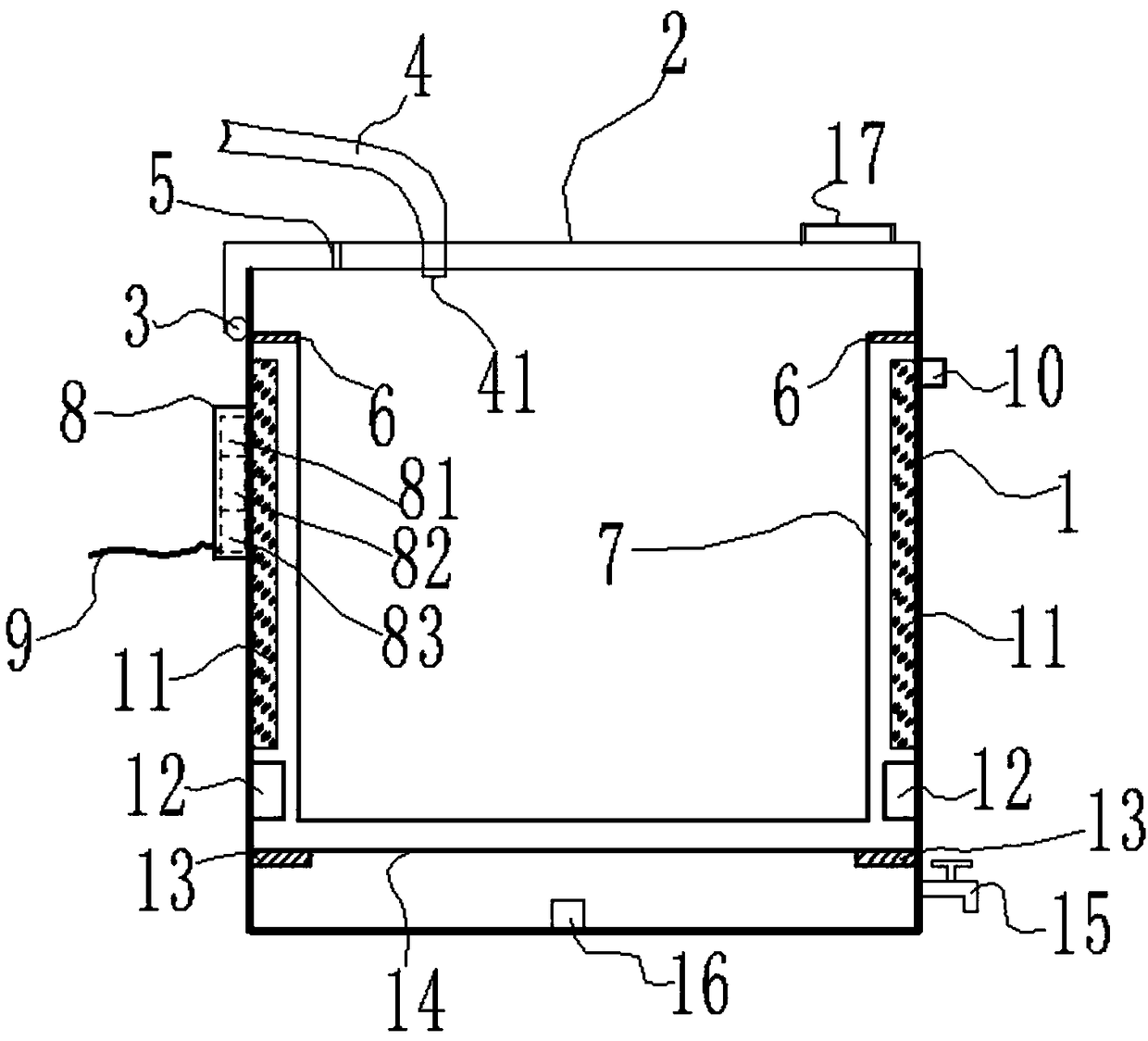

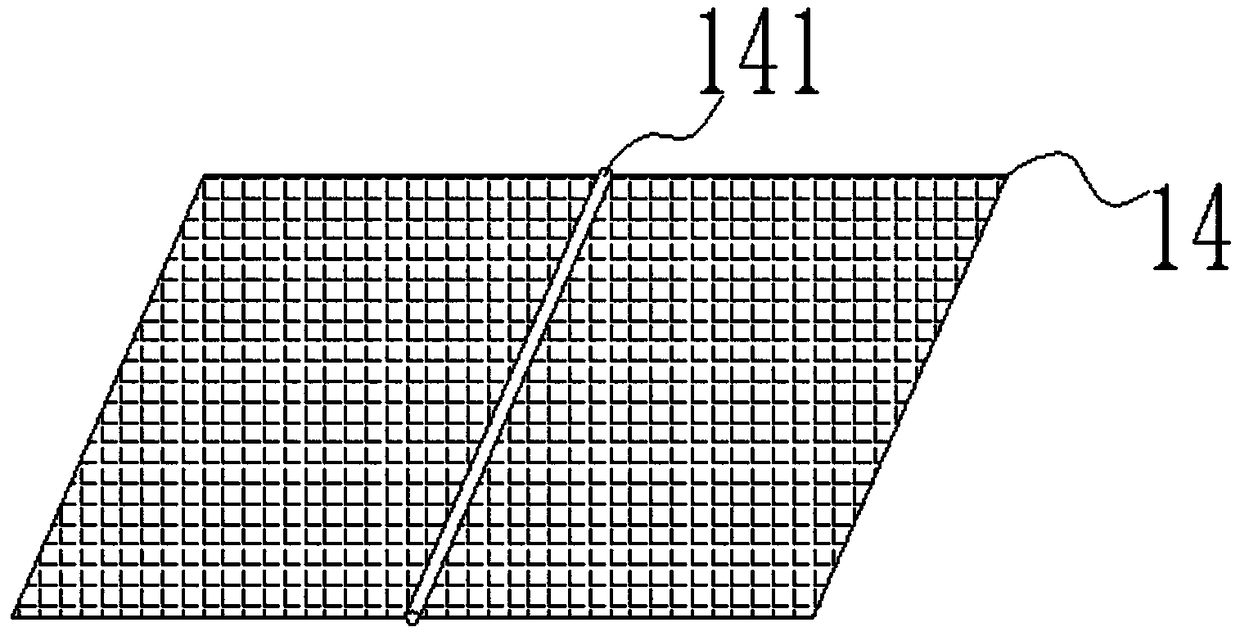

[0042] S2: Heating and separating: put the cassava powder obtained in step S1 into the heating reflux separator, then add pure water to the cassava powder in the heating reflux separator, heat the cassava powder in the reflux separator and The weight ratio of pure water is 1:6, and the heating temperature is 80°C. When the amount of phyllophyll leaf powder added at one time to the heating reflux separator is 1kg, the heating time is 10min. When the amount of the cassava coarse powder exceeds 2kg, the heating time is increased by 5min / 1kg on the basis of 10 minutes, and the cassava mixture A is obtained after ...

Embodiment 2

[0052] A process for extracting trilobatin from Fructus Alba lanceolata, comprising the following steps:

[0053] S1: Grinding of raw materials: select the young leaves of Mujiraecho produced in June, and coarsely pulverize them with a pulverizer to obtain Mujiraeba granules, and sieve the obtained Mujiraeba granules through a 10-mesh sieve to obtain Mujiraecho coarse powder;

[0054] S2: Heating separation: put the cayenne leaf powder obtained in step S1 into a heating reflux separator, the heating reflux separator used is the same as the heating reflux separator used in Example 1, and then the wood in the heating reflux separator Add pure water to the coarse powder of Ginger Yeke, and the weight ratio of the coarse powder of Ginger Yeke to the purified water in the heating reflux separator is 1:11, and the heating temperature is 90°C. When the weight is 1.5kg, the heating time is 10min. When the amount of cassia japonica coarse powder added at one time in the heating reflux ...

Embodiment 3

[0063] A process for extracting trilobatin from Fructus Alba lanceolata, comprising the following steps:

[0064] S1: Raw material crushing: select the tender leaf products of Mujiraecho produced in November, coarsely pulverize through a pulverizer to obtain Mujiraja granules, and sieve the obtained Mujiraeba granules through a 10-mesh sieve to obtain Mujiraegae coarse powder;

[0065]S2: Heating separation: put the cayenne leaf powder obtained in step S1 into a heating reflux separator, the heating reflux separator used is the same as the heating reflux separator used in Example 1, and then the wood in the heating reflux separator Add pure water to the coarse powder of Jiangyeke, heat the weight ratio of the coarse powder of Jiangyeke to the purified water in the reflux separator to 1:20, and the heating temperature is 100°C. When it is 2kg, the heating time is 10min, and when the amount of the coarse powder of Mujiangyeke added at one time in the heating reflux separator exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com