Photo-thermal double-curing 3D printing resin composition

A resin composition, 3D printing technology, applied in the field of 3D printing, can solve the problem of no heat-curable epoxy resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

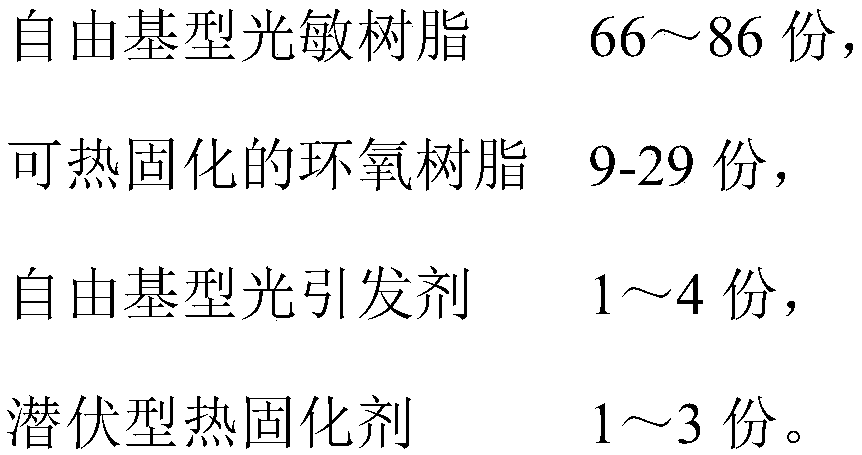

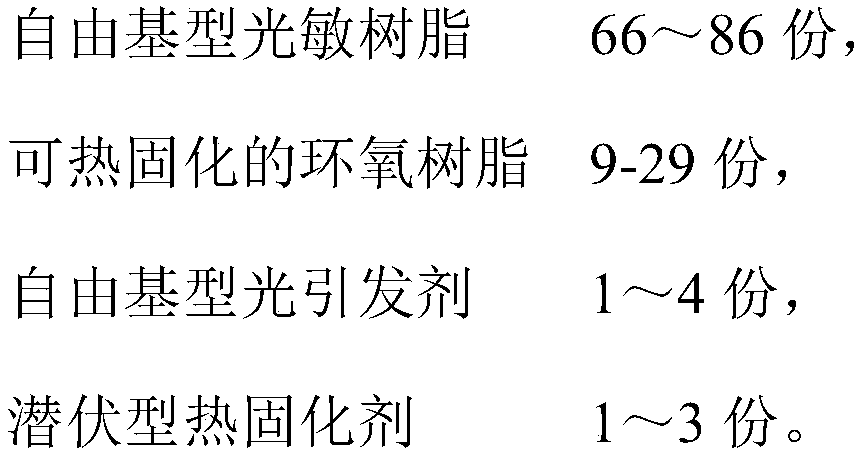

Method used

Image

Examples

Embodiment 1

[0024] A kind of photo-thermal dual curing 3D printing resin composition comprises 43 parts by mass of polyurethane acrylate (U-6282) and 43 parts by mass of pentaerythritol tetraacrylate, 4 parts by mass of photoinitiator 2,4,6-trimethyl Benzoyl-diphenylphosphine oxide, 9 parts by mass of aliphatic epoxy resin 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate, 1 part by mass of imidazole latent heat Curing agent Kingcure 390.

Embodiment 2

[0026] A light-thermal dual curing 3D printing resin composition includes 44 parts by mass of polyether acrylate and 22 parts by mass of trihydroxypropane triacrylate, 2 parts by mass of photoinitiator 2-hydroxyl-2-methyl- 1-phenylacetone, 29 parts by mass of bisphenol A epoxy resin E51, and 3 parts by mass of imidazole latent thermosetting agent Kingcure 390.

Embodiment 3

[0028] A light-thermal hybrid curing 3D printing resin composition includes 46 parts by mass of epoxy acrylate and 30 parts by mass of acryloylmorpholine, and 3 parts by mass of photoinitiator 2-hydroxyl-2-methyl-1-[ 4-(2-hydroxyethoxy)phenyl]-1-propanone, 19 parts by mass of 5,5-dimethylhydantoin epoxy resin, and 2 parts by mass of imidazole latent thermosetting agent Kingcure 390.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com