Preparation and application of highly crosslinked imidazole ionic liquid porous organic polymer

An ionic liquid, cross-linked imidazole technology, applied in the direction of organic compound/hydride/coordination complex catalyst, chemical/physical process, physical/chemical process catalyst, etc., can solve the problem of high substrate requirements, insufficient catalytic activity, Complex operation and other problems, to achieve the effects of huge development potential, wide range of pore volume changes, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

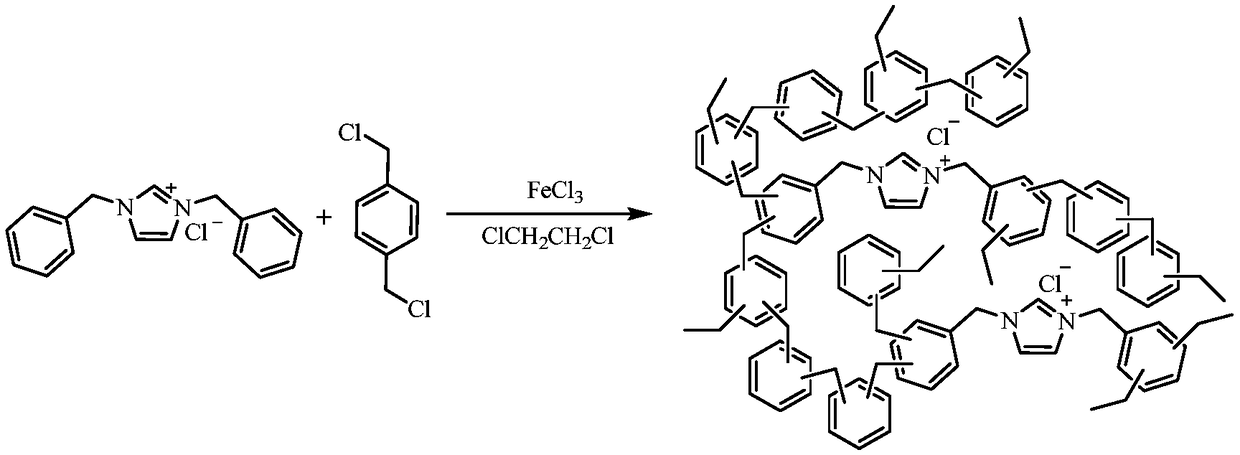

[0018] Weigh 0.28g of 1,3-dibenzyl imidazolium chloride salt, 0.88g of 1,4-p-dichlorobenzyl and 1.62g of ferric chloride catalyst and dissolve it in 20mL of 1,2-dichloroethane. After the reaction was completed, the filtrate was washed three times with methanol and then sucked dry, and was extracted with methanol in a Soxhlet extractor for 24 hours and then vacuum-dried to obtain 0.9 g of the product as a highly cross-linked imidazole ionic liquid porous organic polymer.

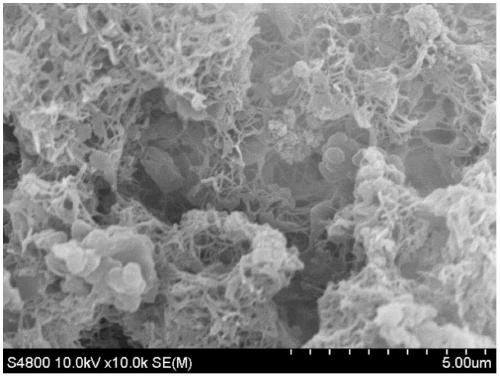

[0019] See attached figure 1 , the above product was characterized by scanning electron microscopy, and the morphology of the obtained polymer was an amorphous porous structure.

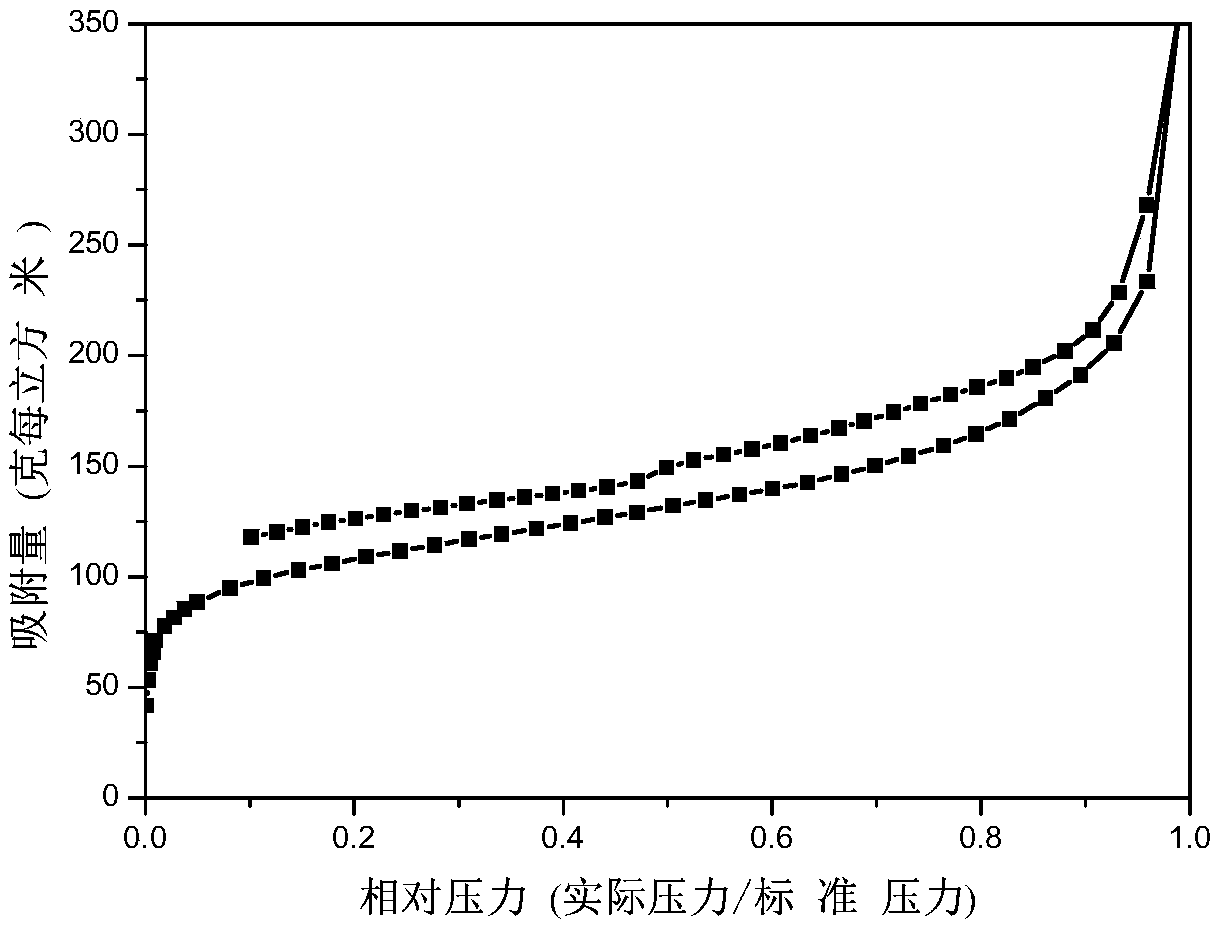

[0020] See attached figure 2 , the above product was characterized by nitrogen adsorption-desorption isotherm, and its specific surface area was 353.9m 2 g -1 , the pore volume is 0.5cm 3 g -1 .

Embodiment 2

[0022] Weigh 0.28g of 1,3-dibenzyl imidazolium chloride salt, 1.65g of 1,4-p-dichlorobenzyl and 1.62g of ferric chloride catalyst and dissolve it in 30mL of 1,2-dichloroethane. Under reaction for 24 hours, after the reaction finished, the filtrate was washed three times with methanol and then sucked dry, and was extracted with methanol in a Soxhlet extractor for 24 hours and then vacuum-dried to obtain 1.3g of the product as a highly cross-linked imidazole ionic liquid porous organic polymer.

Embodiment 3

[0024] Weigh 0.28g of 1,3-dibenzyl imidazolium chloride salt, 1.65g of 1,4-p-dichlorobenzyl and 3.24g of ferric chloride catalyst and dissolve in 40mL of 1,2-dichloroethane. Under reaction for 24 hours, after the reaction finished, the filtrate was washed three times with methanol and then sucked dry, and was extracted with methanol in a Soxhlet extractor for 24 hours and then vacuum-dried to obtain 1.7g of the product as a highly cross-linked imidazole ionic liquid porous organic polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com