A γ-type polyvinylidene fluoride/polybutylene adipate composite material and preparation method thereof

A technology of polybutylene adipate and polyvinylidene fluoride, which is applied in the field of polymer material preparation, can solve the problems of unfavorable standardized production and industrial application, complex preparation process, and various methods involved, and achieve excellent biocompatibility Sexuality, wide application, and excellent biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

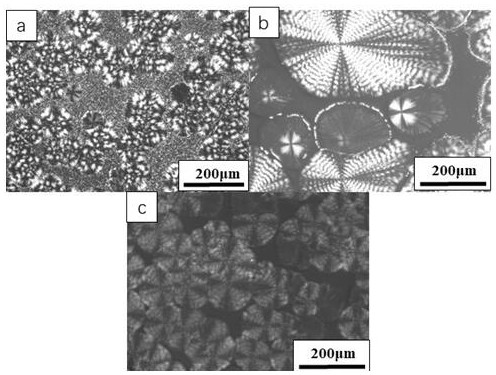

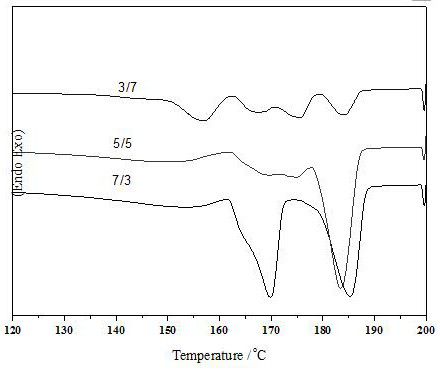

[0023] A preparation method of polyvinylidene fluoride / polybutylene adipate composite material, comprising the following steps:

[0024] 1) Weigh PVDF=0.15g, put it into a 10ml volumetric flask, and mark it as No. 1;

[0025] 2) Weigh PBA=0.35g, put it in No. 1 in step 1), use PVDF and PBA good solvent N,N-dimethylformamide to make up to 10ml, add magnetic stirring rotor at room temperature and magnetically stir for 30min, Make PVDF and PBA dissolve completely, in triplicate, obtain the blend solution that the content of PVDF and PBA is 30wt%;

[0026] 3) The PVDF / PBA solution prepared in step 2) is casted by the solution casting method to obtain a film with a uniform thickness. ℃ vacuum drying for 6 hours;

[0027] 4) Put the composite film prepared in step 3) into a constant temperature heating platform at 200°C, and incubate at a constant temperature for 10 minutes to ensure that the polymer film is fully melted to eliminate the thermal history;

[0028] 5) Rapidly lower...

Embodiment 2

[0031] A preparation method of polyvinylidene fluoride / polybutylene adipate composite material, comprising the following steps:

[0032] 1) Weigh PVDF=0.25g, put it into a 10ml volumetric flask, and mark it as No. 2;

[0033] 2) Weigh PBA=0.25g, put it in No. 2 in step 1), use PVDF and PBA good solvent N,N-dimethylformamide to make up to 10ml, add a magnetic stirring rotor at room temperature and magnetically stir for 30min, Make PVDF and PBA dissolve completely, obtain the blend solution that the content of PVDF and PBA is 50wt%;

[0034] 3) The PVDF / PBA solution prepared in step 2) is casted by the solution casting method to obtain a film with a uniform thickness. ℃ vacuum drying for 6 hours;

[0035] 4) Put the composite film prepared in step 3) into a constant temperature heating platform at 200°C, and incubate at a constant temperature for 10 minutes to ensure that the polymer film is fully melted to eliminate the thermal history;

[0036] 5) Rapidly lower the culture ...

Embodiment 3

[0039] A preparation method of polyvinylidene fluoride / polybutylene adipate composite material, comprising the following steps:

[0040] 1) Weigh PVDF=0.35g, put it into a 10ml volumetric flask, and mark it as No. 3;

[0041]2) Weigh PBA=0.15g, put it in No. 3 of step 1), use PVDF and PBA good solvent N,N-dimethylformamide to make the volume to 10ml, add magnetic stirring rotor at room temperature and magnetically stir for 30min, make PVDF and PBA are completely dissolved to obtain a blend solution in which the content of PVDF and PBA is 70wt%;

[0042] 3) The PVDF / PBA solution prepared in step 2) is casted by the solution casting method to obtain a film with a uniform thickness. ℃ vacuum drying for 6 hours;

[0043] 4) Put the composite film prepared in step 3) into a constant temperature heating platform at 200°C, and incubate at a constant temperature for 10 minutes to ensure that the polymer film is fully melted to eliminate the thermal history;

[0044] 5) Rapidly lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com