A paint compounding additive for reducing vehicle painting cost

A technology for compounding additives and paints, applied in coatings and other directions, can solve the problems of paint, thinner, curing agent waste, inability to improve paint utilization efficiency, and inability to cover parts, etc., to save paint, excellent interface properties and mechanical properties, Improves paint adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

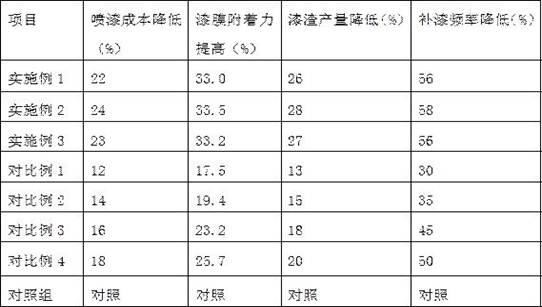

Examples

Embodiment 1

[0017] A paint compounding additive for reducing vehicle painting costs, which is made of the following components in parts by weight: 20 parts of polyethyleneimine, 5 parts of concentrated hydrochloric acid, 1.8 parts of carboxymethyl cellulose, 0.12 parts of catalyst, phthalic acid 15 parts, 60 parts of ethanol, 2.5 parts of ethylenediamine, 3.0 parts of graphene oxide, 1.2 parts of zirconia powder, 0.8 parts of vinyltriethoxysilane, 10 parts of water, and 1.5 parts of buffer solution. The preparation method comprises the following steps:

[0018] (1) Put polyethyleneimine, phthalic acid, and ethanol in a three-necked flask, slowly add concentrated hydrochloric acid dropwise in an ice-water bath at 0°C, and stir mechanically for 15 minutes, then slowly add ethylenediamine dropwise, and the material is added dropwise After finishing, add graphene oxide and catalyst, raise the temperature to 30°C, react at constant temperature for 2 hours, and obtain the reaction liquid to cool...

Embodiment 2

[0026] A paint compounding additive for reducing vehicle painting costs, which is made of the following components in parts by weight: 22 parts of polyethyleneimine, 5.5 parts of concentrated hydrochloric acid, 1.9 parts of carboxymethyl cellulose, 0.13 parts of catalyst, phthalic acid 16 parts, 65 parts of ethanol, 2.6 parts of ethylenediamine, 3.3 parts of graphene oxide, 1.3 parts of zirconia powder, 0.9 parts of vinyltriethoxysilane, 11 parts of water, and 1.8 parts of buffer solution. The preparation method comprises the following steps:

[0027] (1) Put polyethyleneimine, phthalic acid, and ethanol in a three-necked flask, slowly add concentrated hydrochloric acid dropwise in an ice-water bath at 2°C, and stir mechanically for 18 minutes, then slowly add ethylenediamine dropwise, and the material is added dropwise After that, add graphene oxide and catalyst, raise the temperature to 33°C, react at constant temperature for 2.5 hours, and obtain the reaction liquid to cool ...

Embodiment 3

[0035] A paint compounding additive for reducing vehicle painting costs, which is made of the following components in parts by weight: 25 parts of polyethyleneimine, 6 parts of concentrated hydrochloric acid, 2.0 parts of carboxymethyl cellulose, 0.14 parts of catalyst, phthalic acid 18 parts, 70 parts of ethanol, 2.8 parts of ethylenediamine, 3.5 parts of graphene oxide, 1.4 parts of zirconia powder, 1.0 parts of vinyltriethoxysilane, 12 parts of water, and 2.0 parts of buffer solution. The preparation method comprises the following steps:

[0036] (1) Put polyethyleneimine, phthalic acid, and ethanol in a three-necked flask, slowly add concentrated hydrochloric acid dropwise in an ice-water bath at 5°C, and stir mechanically for 20 minutes, then slowly add ethylenediamine dropwise, and the material is added dropwise After finishing, add graphene oxide and catalyst, raise the temperature to 35°C, react at constant temperature for 3 hours, and obtain the reaction liquid to cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com