Back coating liquid for thermal transfer printing carbon ribbon and thermal sublimation carbon ribbon and preparation method thereof

A thermal sublimation, thermal transfer technology, applied in coating, printing, ink ribbon and other directions, can solve problems such as cost increase, failure to meet the requirements of heat resistance, waste of heat energy, etc., to achieve low energy consumption, energy saving, lower energy consumption cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

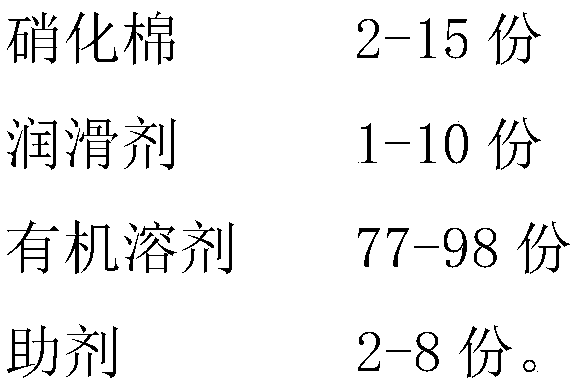

Method used

Image

Examples

Embodiment 1

[0025] Nitrocellulose 3 grams

[0026] Silicone oil 2 grams

[0027] Leveling agent BYK333 2g

[0028] Methyl ethyl ketone 46g

[0029] Toluene 47g

[0030] Weigh 46 grams of methyl ethyl ketone and 47 grams of toluene into the mixing tank, then weigh 3 grams of nitrocellulose, slowly add in the mixed solution of methyl ethyl ketone and toluene while stirring, stir evenly and dissolve completely, Weigh 2 grams of silicone oil and 2 grams of leveling agent BYK333 into the mixing tank and stir evenly. The whole process is carried out at room temperature.

[0031] The back coating solution is applied to thermal transfer printing and thermal sublimation carbon ribbons at 0.2 grams per square meter to meet the requirements of carbon ribbons for back coating. Heat resistance instantaneous temperature 260 degrees. Friction coefficient Kd<0.2. It is no problem to continuously print 30 rolls of 110X300m carbon ribbon with a Zebra 300dpi barcode printer at 14 degrees. No powder ...

Embodiment 2

[0033] Nitrocellulose 5g

[0034] Dispersant SP-725 2 grams

[0035] Silicone oil 2 grams

[0036] 40g methyl ethyl ketone

[0037] Toluene 51g

[0038] In the production process, weigh 40 grams of methyl ethyl ketone and 51 grams of toluene and add them to the mixing tank, then weigh 5 grams of nitrocellulose, slowly add them to the mixed solution of methyl ethyl ketone and toluene while stirring, and stir evenly and completely After dissolving, weigh 2 grams of silicone oil and 2 grams of dispersant SP-725, add them into the mixing tank and stir evenly. The whole process is carried out at room temperature.

[0039] The back coating solution is applied to thermal transfer printing and thermal sublimation carbon ribbons at 0.2 grams per square meter to meet the requirements of carbon ribbons for back coating. Heat resistance instantaneous temperature 260 degrees. Friction coefficient Kd<0.2. It is no problem to continuously print 30 rolls of 110X300m carbon ribbon with ...

Embodiment 3

[0041] Nitrocellulose 10g

[0042] Modified silicone 2 grams

[0043] Antistatic agent FA14 3 grams

[0044] Methyl ethyl ketone 42g

[0045] 43 grams of toluene

[0046] During the production process, weigh 42 grams of methyl ethyl ketone and 43 grams of toluene and add them to the mixing tank, then weigh 10 grams of nitrocellulose, slowly add the mixed solution of methyl ethyl ketone and toluene while stirring, and stir evenly and completely After dissolving, weigh 2 grams of modified silicone and 3 grams of antistatic agent FA14, add them into the mixing tank and stir evenly. The whole process is carried out at room temperature.

[0047] The back coating solution is applied to thermal transfer printing and thermal sublimation carbon ribbons at 0.2 grams per square meter to meet the requirements of carbon ribbons for back coating. Heat resistance instantaneous temperature 260 degrees. Friction coefficient Kd<0.2. It is no problem to continuously print 30 rolls of 110X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com