Method for removing thiophene-type sulfide in fuel oil by using Pd (II)-SiO<2> composite aerogel as adsorbent

A technology of composite airgel and adsorbent, which is applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc. It can solve the problems of providing active sites, low sulfur removal rate, and inability to effectively remove multiple sulfides at the same time , to achieve good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

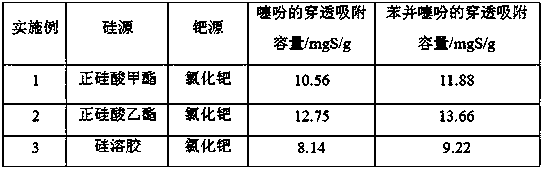

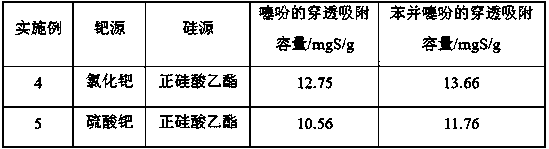

[0026] Embodiment 1~5: Pd(II)-SiO of different silicon sources and palladium sources 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0027] Pd(Ⅱ)-SiO with a silicon-palladium molar ratio of 320 prepared by the sol-gel method 2 In the composite airgel adsorbent, the silicon sources used include methyl orthosilicate, ethyl orthosilicate, and silica sol, and the palladium sources include palladium sulfate and palladium chloride. The prepared Pd(Ⅱ)-SiO 2 The composite aerogel was subjected to the penetration adsorption desulfurization experiment, and the specific operation was as follows: an appropriate amount of absorbent cotton was filled in the bottom layer of the fixed bed adsorption device, and then 1 g of Pd(Ⅱ)-SiO 2 Composite airgel with appropriate amount of quartz sand. Before the adsorption experiment started, the packed adsorbent was fully wetted with n-heptane. Inject simulated gasoline (1mgS / g) at 25°C with a space velocity...

Embodiment 6~10

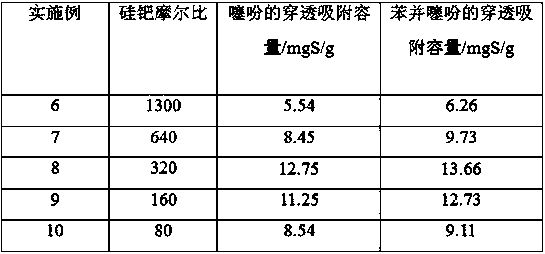

[0033] Embodiment 6~10: Pd(II)-SiO with different silicon-palladium molar ratios 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0034] Select Pd(II)-SiO with silicon-palladium molar ratios of 1300, 640, 320, 160 and 110 respectively 2 Airgel, other conditions are the same as the Pd(Ⅱ)-SiO prepared in Example 2 2 Composite airgel, through adsorption experiments on thiophene sulfides in simulated gasoline. The operation of the breakthrough adsorption experiment is the same as in Examples 1-5, and the adsorption results are shown in Table 3.

[0035] Table 3 Pd(Ⅱ)-SiO with different molar ratios of silicon to palladium 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0036]

[0037] As can be seen from Table 3, Pd(Ⅱ)-SiO 2 As the molar ratio of silicon to palladium decreases, that is, the content of palladium increases, the breakthrough adsorption capacity of thiophene and benzothiophene...

Embodiment example 11~15

[0038] Implementation Cases 11~15: Effect of different simulated gasoline injection space velocities on Pd(Ⅱ)-SiO 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0039] Use Pd(II)-SiO with a silicon-palladium molar ratio of 320 2 Composite airgel adsorbent. at an airspeed of 1 h -1 、2h -1 、4h -1 、6h -1 , 8 hours -1 Next, the breakthrough adsorption experiment was carried out on thiophene sulfides in simulated gasoline. The operation of the breakthrough adsorption experiment is the same as in Examples 1-5, and the adsorption results are shown in Table 4.

[0040] Table 4 Pd(Ⅱ)-SiO at different space velocities 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0041]

[0042] It can be seen from Table 4 that with the increase of the simulated gasoline injection space velocity, the breakthrough adsorption capacity of thiophene and benzothiophene will gradually decrease. When the space ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakthrough adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com